Dairy cow nipple antifreezing disinfector and preparation method thereof

A technology for cow teats and disinfectants, which is applied in the direction of pharmaceutical formulas, local antibacterial agents, medical preparations with non-active ingredients, etc., can solve the problems of low skin surface temperature and poor protective effect, and achieve simple operation and improved film formation Effect, the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of embodiment of milk cow teat antifreeze disinfectant of the present invention, the composition and preparation method of milk cow teat antifreeze disinfectant described in the present embodiment are as follows:

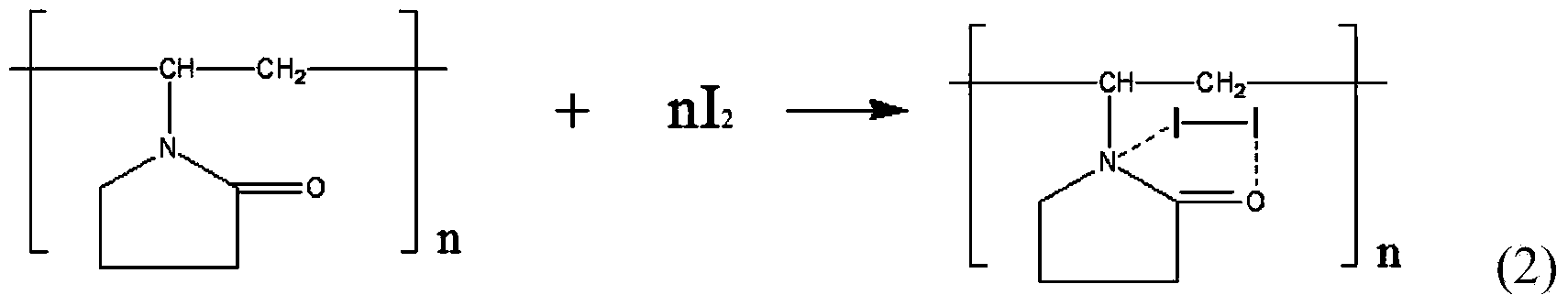

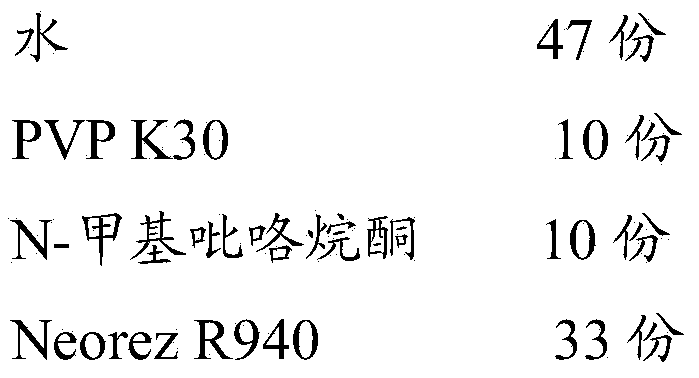

[0029] (1) Preparation of polymer film-forming agent

[0030]

[0031] In a four-neck flask equipped with a reflux condenser, a stirrer, and a thermometer, add water, N-methylpyrrolidone, NeorezR940, and PVPK30 respectively, stir and raise the temperature to 65°C, and keep the temperature for 0.5h to obtain a polymer film-forming agent;

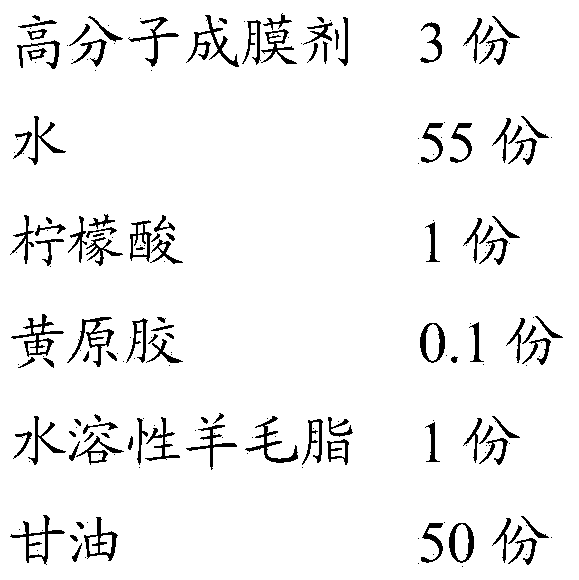

[0032] (2) Preparation of products

[0033]

[0034]

[0035] In a four-neck flask equipped with a reflux condenser, a stirrer, and a thermometer, add water, citric acid, and xanthan gum respectively, heat and stir to raise the temperature to 50-60°C, and keep the temperature for 1 hour; add a polymer film-forming agent, 50-60°C heat preservation reaction for 1 hour; add water-soluble lanolin, glycerin, potass...

Embodiment 2

[0037] A kind of embodiment of milk cow teat antifreeze disinfectant of the present invention, the composition and preparation method of milk cow teat antifreeze disinfectant described in the present embodiment are as follows:

[0038] (1) Preparation of polymer film-forming agent

[0039]

[0040] In a four-necked flask equipped with a reflux condenser, a stirrer, and a thermometer, add water, N-methylpyrrolidone, NeorezR9403, and PVPK30 respectively, stir and heat up to 65°C, and keep the temperature for 2 hours to obtain a polymer film-forming agent;

[0041] (2) Preparation of products

[0042]

[0043] In a four-necked flask equipped with a reflux condenser, a stirrer, and a thermometer, add water, acetic acid, and xanthan gum respectively, heat and stir to raise the temperature to 50-60°C, and keep the temperature for 0.5 hours; add a polymer film-forming agent, 50 ~60°C heat preservation reaction for 2 hours; add OT-75, propylene glycol, potassium iodate, potassi...

Embodiment 3

[0045] A kind of embodiment of milk cow teat antifreeze disinfectant of the present invention, the composition and preparation method of milk cow teat antifreeze disinfectant described in the present embodiment are as follows:

[0046] (1) Preparation of polymer film-forming agent

[0047]

[0048] In a four-necked flask equipped with a reflux condenser, a stirrer, and a thermometer, add water, N-methylpyrrolidone, NeorezR940, and PVPK30 respectively, stir and heat up to 65°C, and keep the temperature for 2 hours to obtain a polymer film-forming agent;

[0049] (2) Preparation of products

[0050]

[0051] In a four-neck flask equipped with a reflux condenser, a stirrer, and a thermometer, add water, citric acid, and xanthan gum respectively, heat and stir to raise the temperature to 50-60°C, and keep the temperature for 1 hour; add a polymer film-forming agent, 50-60°C heat preservation reaction for 3 hours; add water-soluble lanolin, glycerin, potassium iodate, potass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com