Method of anti-leak treatment on petroleum drilling place by adopting composite geo-membrane

A composite geomembrane, oil drilling technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problem of not involving the technical content of the composite geomembrane oil drilling site, the inability to obtain idle land, and the ineffectiveness of preventing leakage. and other problems, to achieve the effect of improving the anti-leakage effect, preventing pollution and facilitating drilling construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

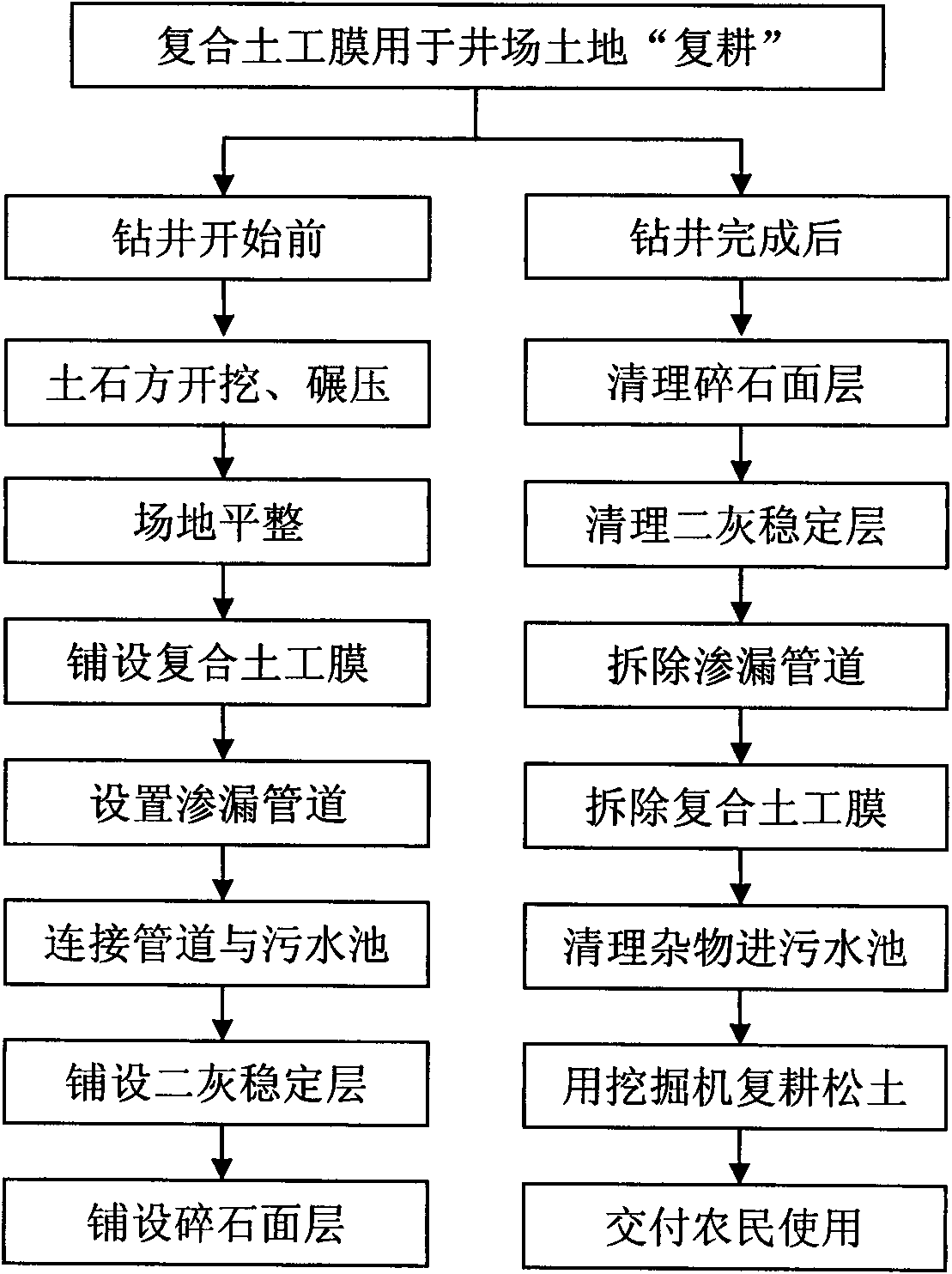

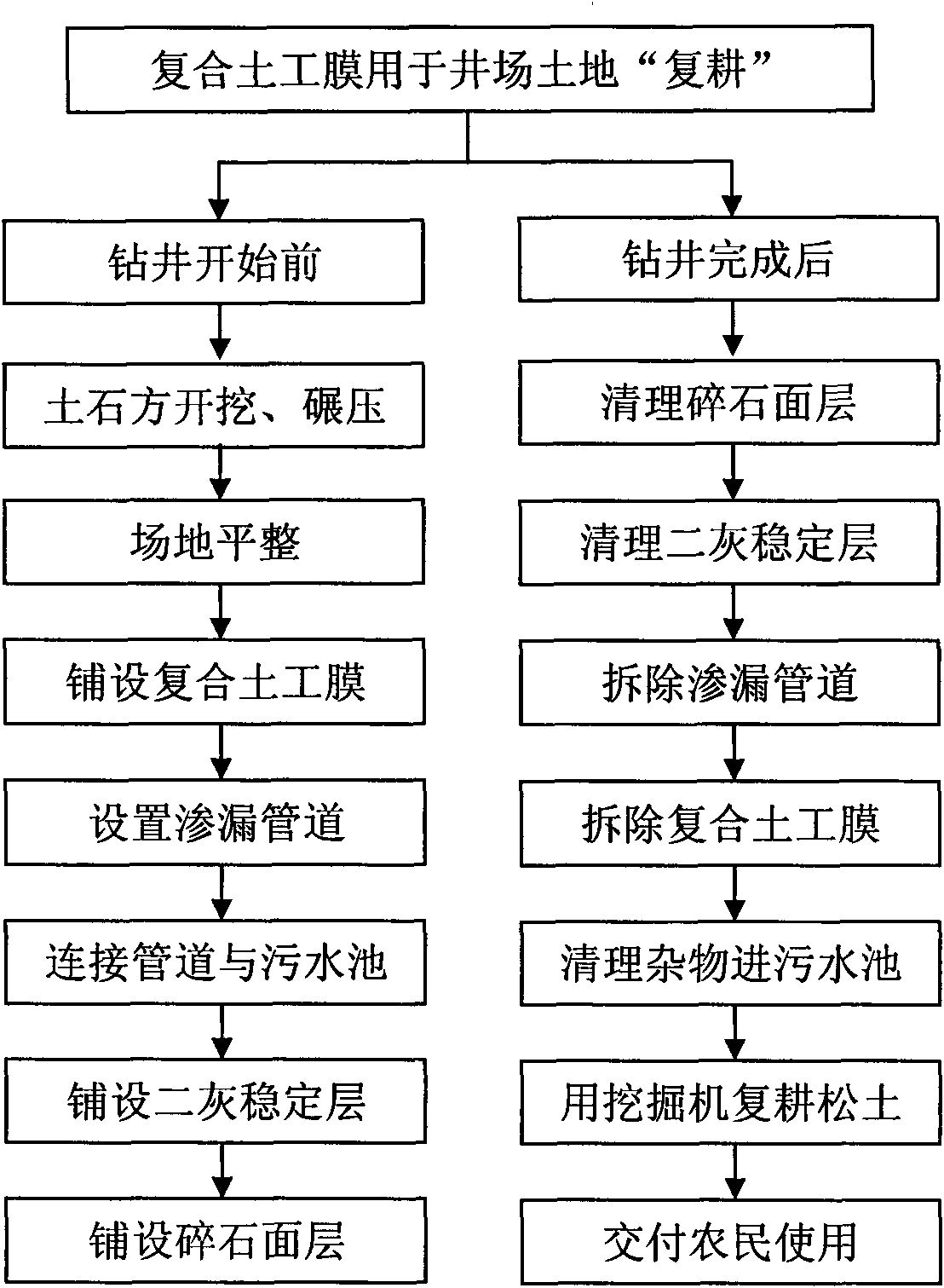

[0038] The invention discloses a method for anti-leakage treatment of an oil drilling site by using a composite geomembrane. The following steps are adopted:

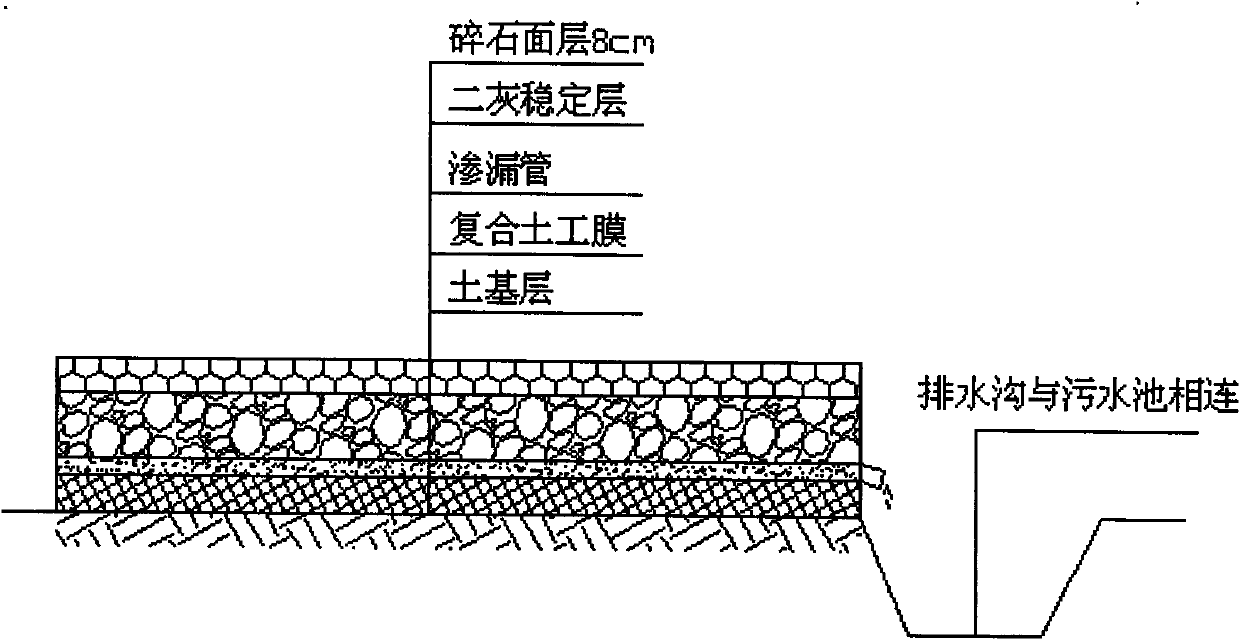

[0039] a. Site leveling: Before laying the composite geomembrane, carry out the operation according to the conventional site leveling operation procedure; b. Laying the composite geomembrane: first level the base surface with sand or clay with a small particle size, and then lay the composite geomembrane on the base surface. Geomembrane, the two ends of the composite geomembrane embedded in the soil are corrugated, and finally a transitional layer is laid on the composite geomembrane with fine sand or clay, and the joints between multiple composite geomembranes are processed; c, laying Leakage pipes: Arrange leakage pipes at places prone to leakage; d. Lay fly ash stabilized layer: use crushed stone, lime and fly ash as raw materials, lay fly ash stabilized layer on the composite geomembrane, according to the total amoun...

Embodiment 2

[0041] As a preferred embodiment of the present invention, in step d, when the fly ash stabilized layer is laid on the composite geomembrane, the laying of the fly ash stabilized layer is carried out while the film is being laid. In the step b, the laying thickness of the transitional layer is 2cm. In the b step, the seam treatment method adopts the heat welding method, and the overlap width of the weld seam in the heat welding is not less than 8cm. In the step b, the laying thickness of the composite geomembrane is not less than 0.25mm. In the b step, the connection between the composite geomembrane and the surrounding structures is anchored by expansion bolts and steel plate beading, and then the emulsified asphalt is painted on the connection part for bonding, and the thickness of the emulsified asphalt is more than 2mm. In the step c, the place prone to leakage refers to the seam, the weight pump, the machine room or the connection between the composite geomembrane and th...

Embodiment approach

[0043] With reference to the accompanying drawings of the description, as the best embodiment of the present invention is as follows:

[0044] a. Site leveling:

[0045] Before the composite geomembrane is laid, the operation shall be carried out according to the conventional site leveling operation procedure. It mainly includes earth-rock blasting, earth-rock excavation, earth-rock allocation, site leveling and compaction and other processes.

[0046] b. Laying composite geomembrane

[0047] During construction, the base surface should be leveled first with sand or clay with small particle size, and then the composite geomembrane should be laid. The composite geomembrane should not be stretched too tightly, and the parts buried in the soil at both ends are corrugated. Finally, a layer of about 2cm is laid on the geomembrane with fine sand or clay. Lay a 20cm fly ash stable layer as an anti-scour protection layer. During construction, try to protect the geomembrane. It is be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com