Mineral hydraulic bracket controller, bracket control system and communication method

A technology of hydraulic support and communication method, which is applied in the direction of mine roof support, pillar/support, comprehensive factory control, etc. It can solve the problems of inability to realize long-distance high-speed data transmission and the limitation of the number of network nodes, so as to improve the transmission rate and Effects of noise immunity, reduced points of failure, parts and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

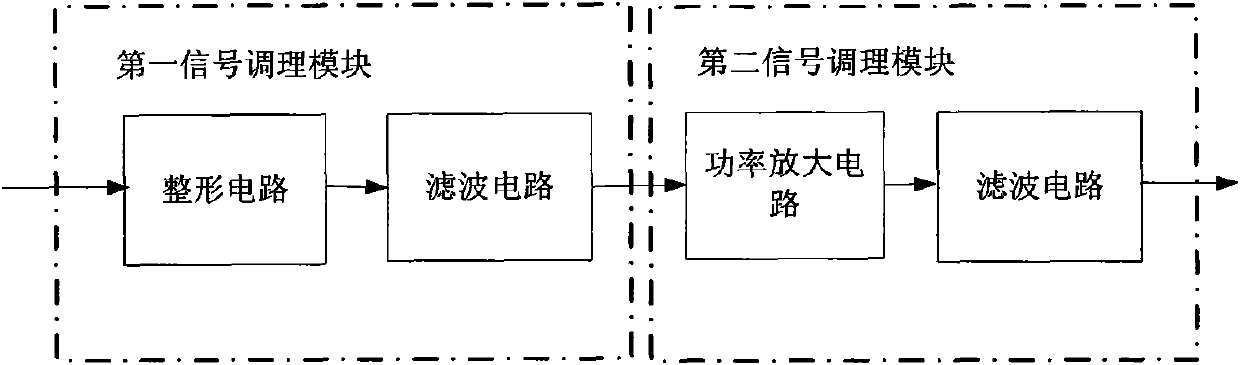

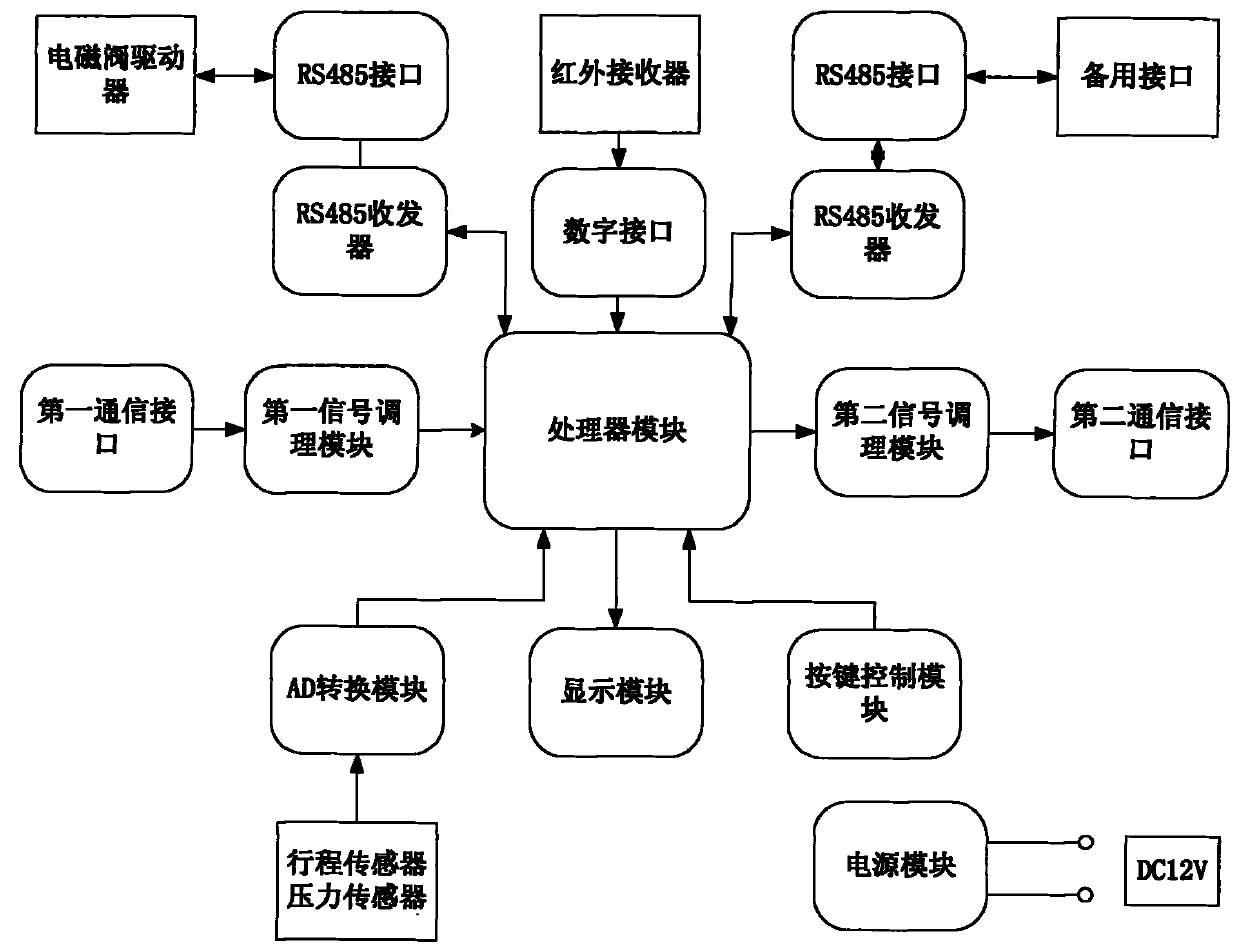

[0024] figure 2 It is a structural schematic diagram of the mine hydraulic support controller of the present invention, as shown in the figure, including a processor module as a central processing unit, and the processor module is connected with two signal conditioning modules, namely the first signal conditioning module in the figure , the second signal conditioning module (any signal conditioning module acts as the role of the first signal conditioning module when receiving the data frame signal, and acts as the role of the second signal conditioning module when transmitting the data frame signal); each signal conditioning module communicates with a Interface connection, that is, the first communication interface and the second communication interface in the figure. In the present invention, when the mine hydraulic support controller is used as the source sending end of the data signal, the processor module is responsible for generating the data frame signal according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com