Surface protection film

A protective film and non-crystalline technology, applied in the direction of film/sheet adhesives, synthetic resin layered products, chemical instruments and methods, etc., can solve printing defects, change the surface properties of the adherend, and be difficult to extract, etc. problem, to achieve the effect of excellent blocking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

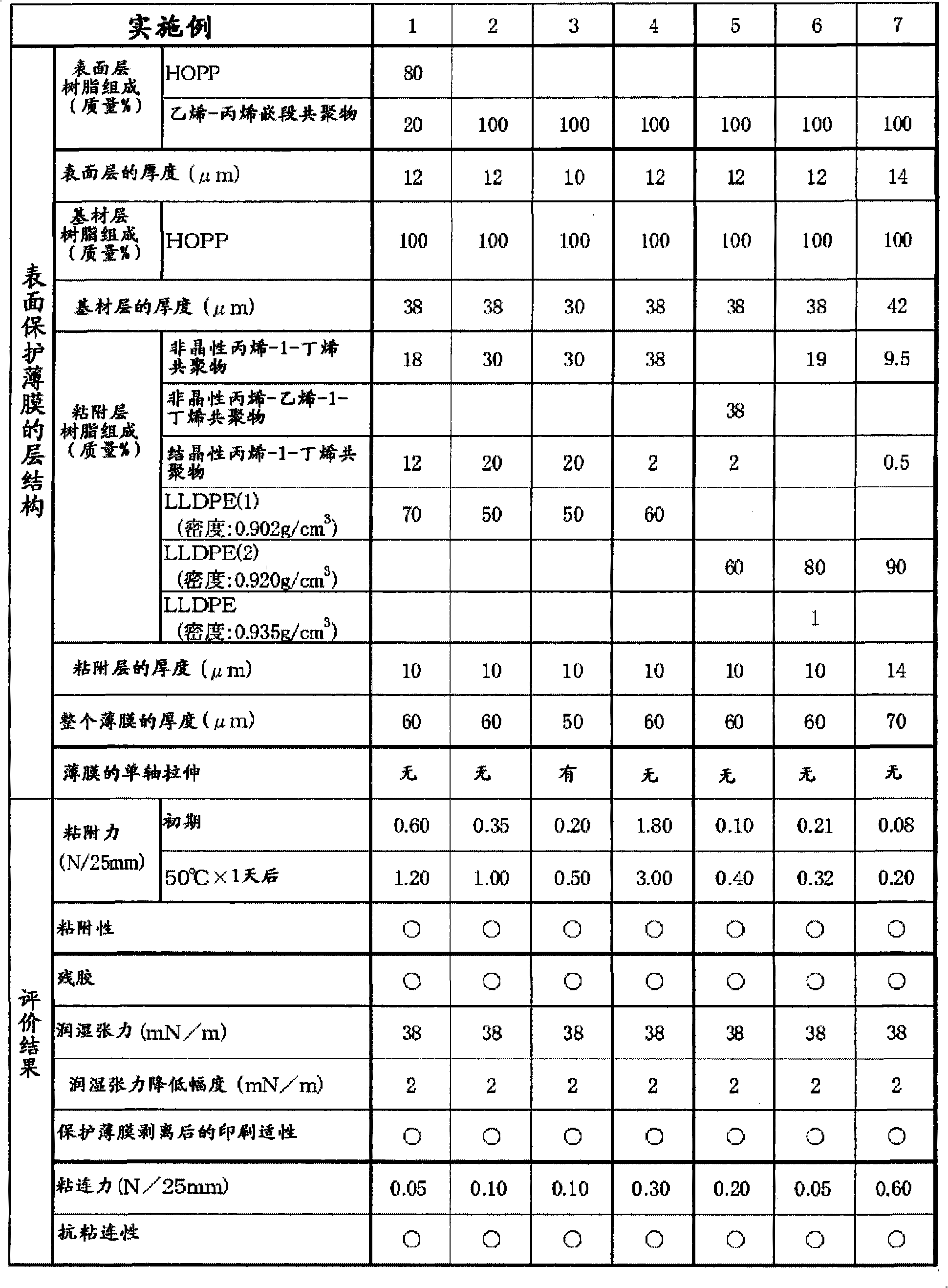

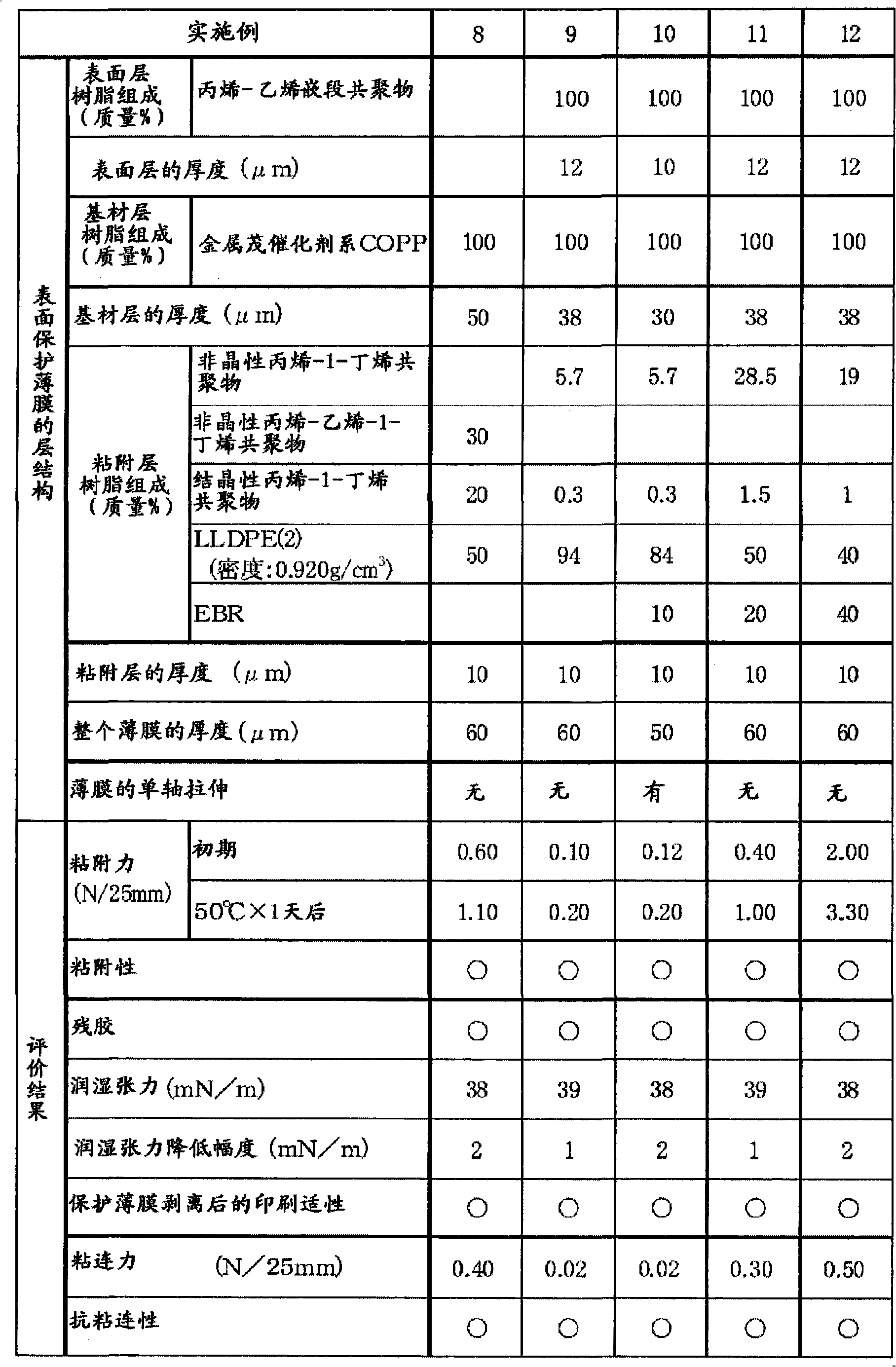

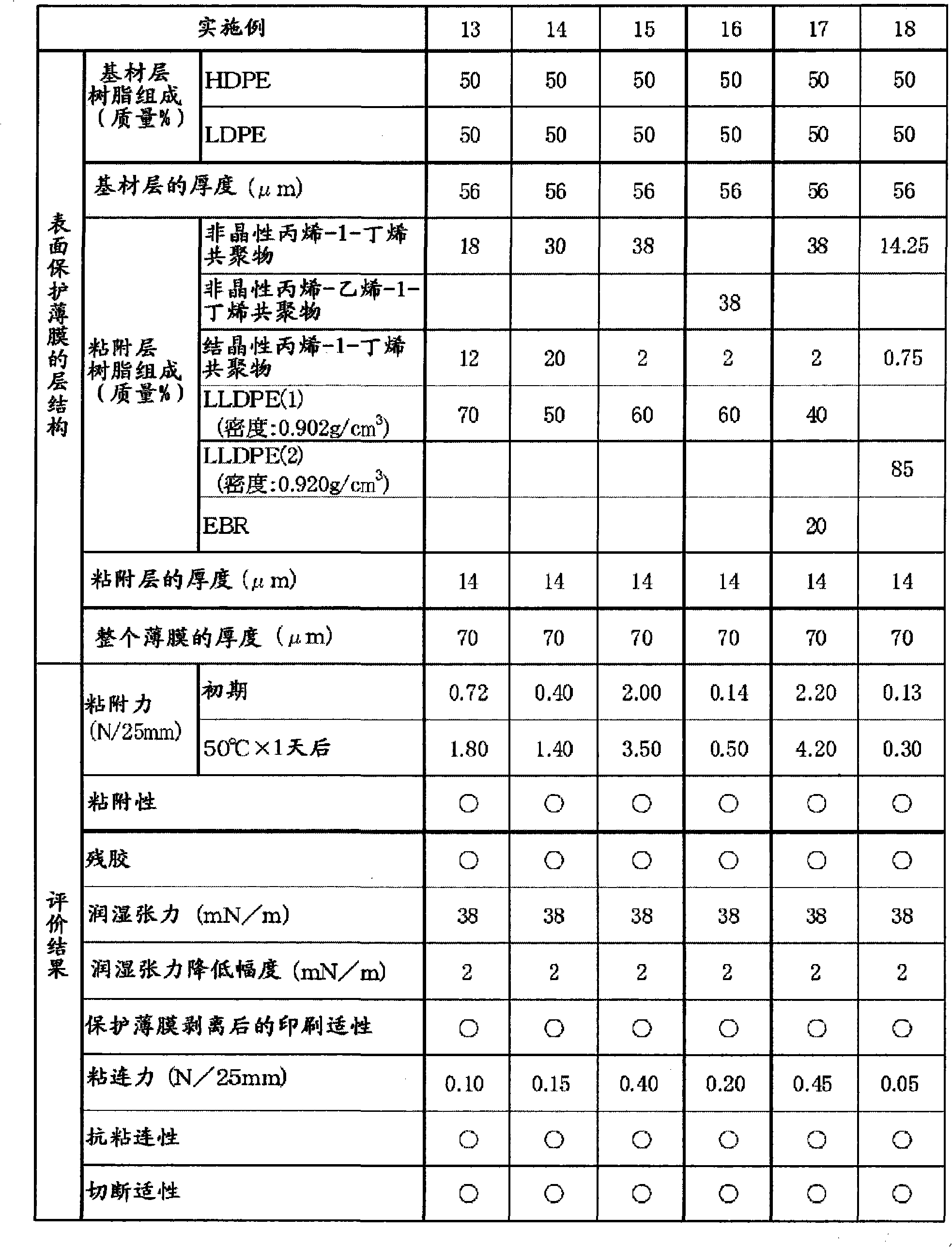

[0058] Examples and comparative examples are given below to specifically describe the present invention.

Synthetic example 1

[0060] [Synthesis of Amorphous α-Olefin Polymer (Amorphous Propylene-1-Butene Copolymer)]

[0061]In a 100L stainless steel polymerization vessel equipped with a stirrer, propylene and 1-butene were continuously copolymerized using hydrogen as a molecular weight modifier to obtain amorphous propylene-1-butene as an amorphous α-olefin polymer. Butene copolymer. Specifically, from the lower part of the polymerizer, the polymerization solvents hexane, propylene, and 1-butene were continuously supplied at a feed rate of 100 L / hour, 24.00 kg / hour, and 1.81 kg / hour, respectively, and from the upper part of the polymerizer, continuously The reaction mixture was withdrawn steadily to keep the reaction mixture in the polymerizer at 100 L. In addition, dimethylsilyl (tetramethylcyclopentadienyl) as a catalyst component was continuously supplied from the lower part of the polymerizer at feed rates of 0.005 g / hour, 0.298 g / hour, and 2.315 g / hour, respectively. (3-tert-butyl-5-methyl-2-p...

Synthetic example 2

[0063] [Synthesis of Amorphous α-Olefin Polymer (Amorphous Propylene-Ethylene-1-Butene Copolymer)]

[0064] A 2 L detachable flask reactor equipped with a stirrer, a thermometer, a dropping funnel, and a reflux condenser was decompressed and replaced with nitrogen, and then 1 L of dry toluene was introduced as a polymerization solvent. At this time, under normal pressure, 2×10 -6 cm 3 / min, 4×10 -6 cm 3 / min, 1×10 -6 cm 3 Ethylene, propylene and 1-butene were continuously fed at a feed rate of 1 / min, and the solvent temperature was controlled at 30°C. After adding 0.75 mmol triisobutylaluminum (hereinafter referred to as TIBA) to the polymerization tank, add 0.0015 mmol dimethylsilyl (tetramethylcyclopentadienyl) (3-tert-butyl- 5-methyl-2-phenoxy)titanium dichloride. After 15 seconds, 0.0075 mmol of triphenylmethyltetrakis(pentafluorophenyl) borate was added to the polymerization tank, and polymerization was carried out for 10 minutes. As a result, an amorphous propyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com