Multipurpose sheet metal stamping die-set for positive edge pressing

A sheet metal stamping, multi-purpose technology, used in metal processing equipment, forming tools, manufacturing tools, etc., can solve problems such as pressure rise, high-speed descending, causing accidents, etc., to improve work ability, safety, and novel structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

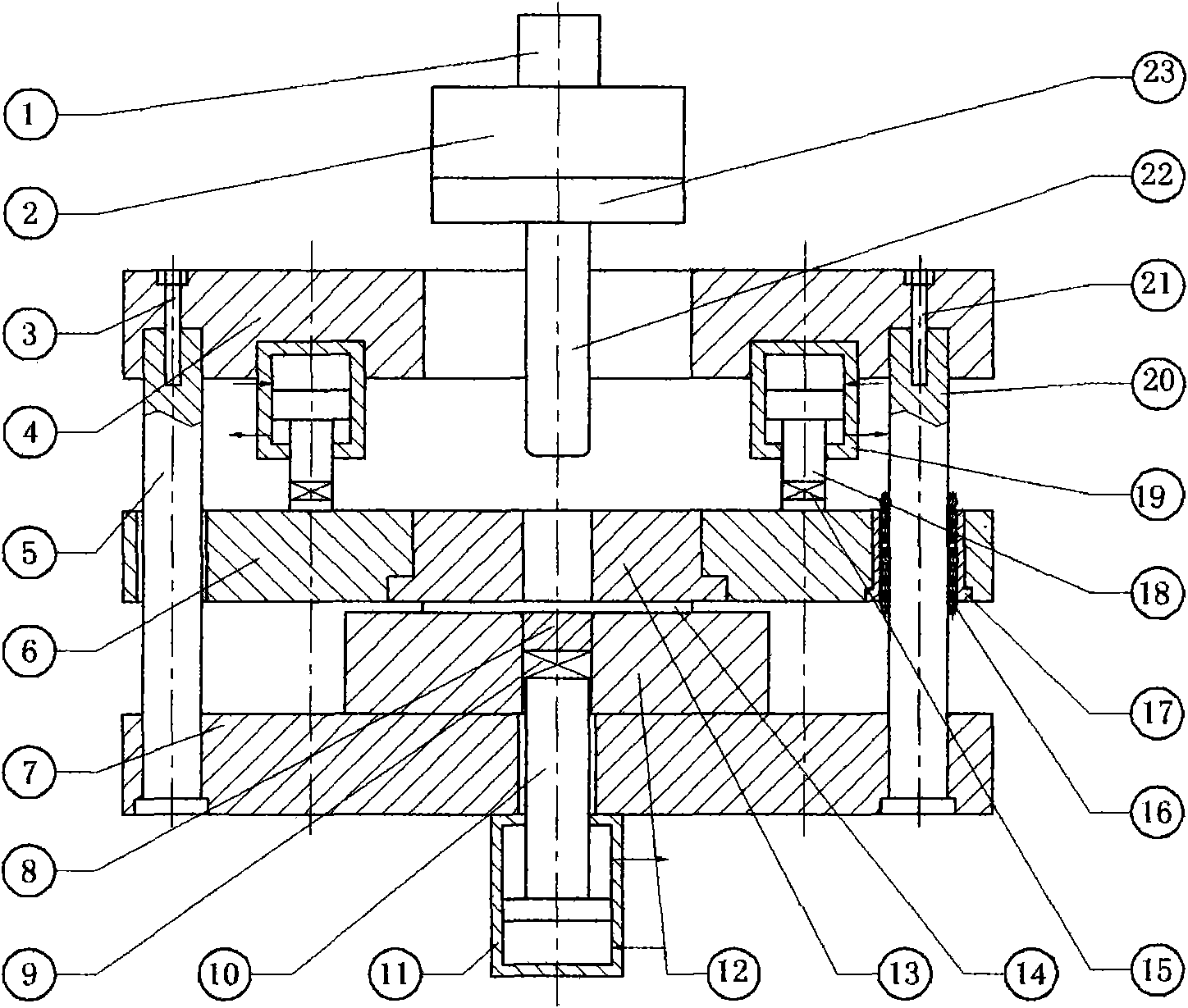

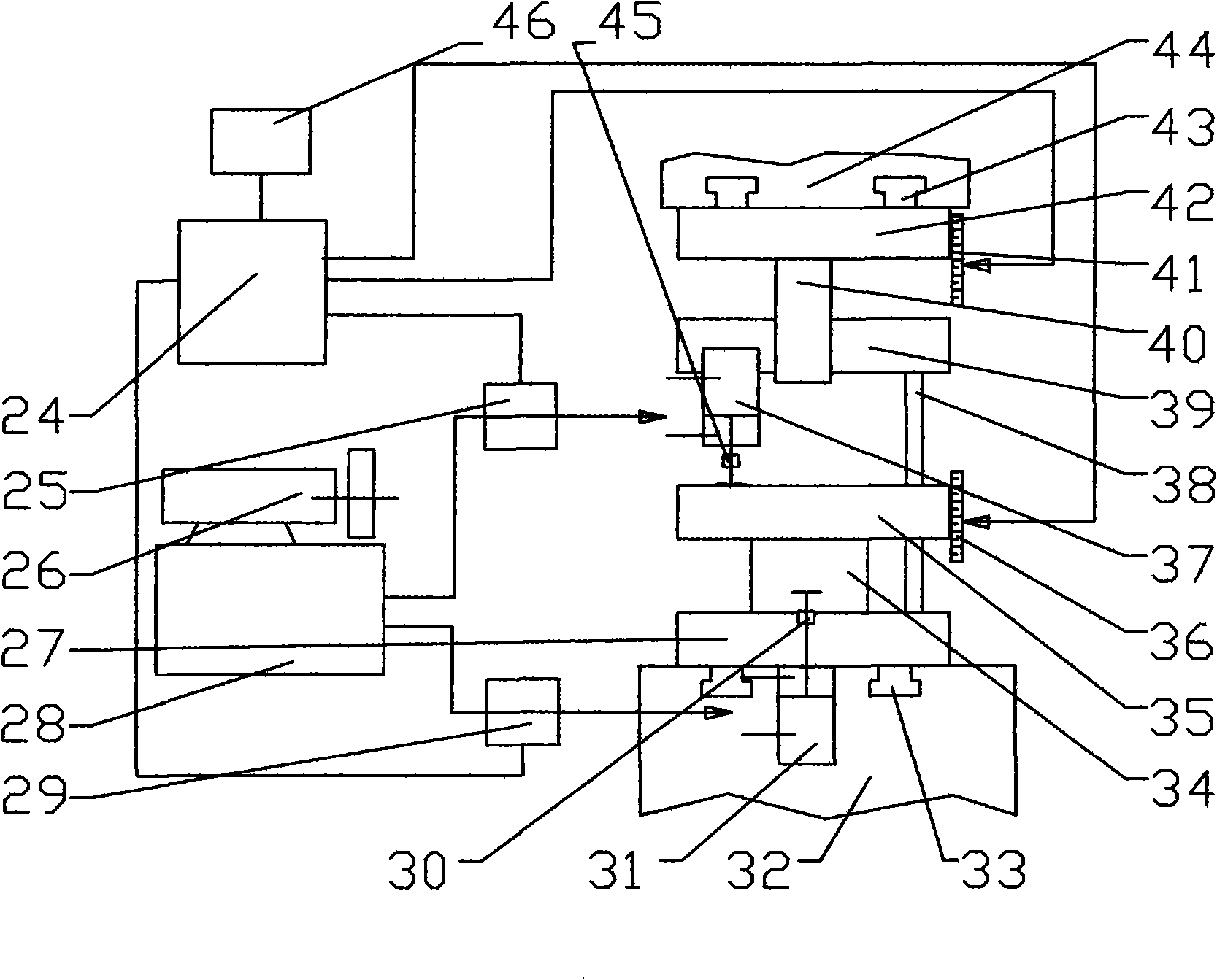

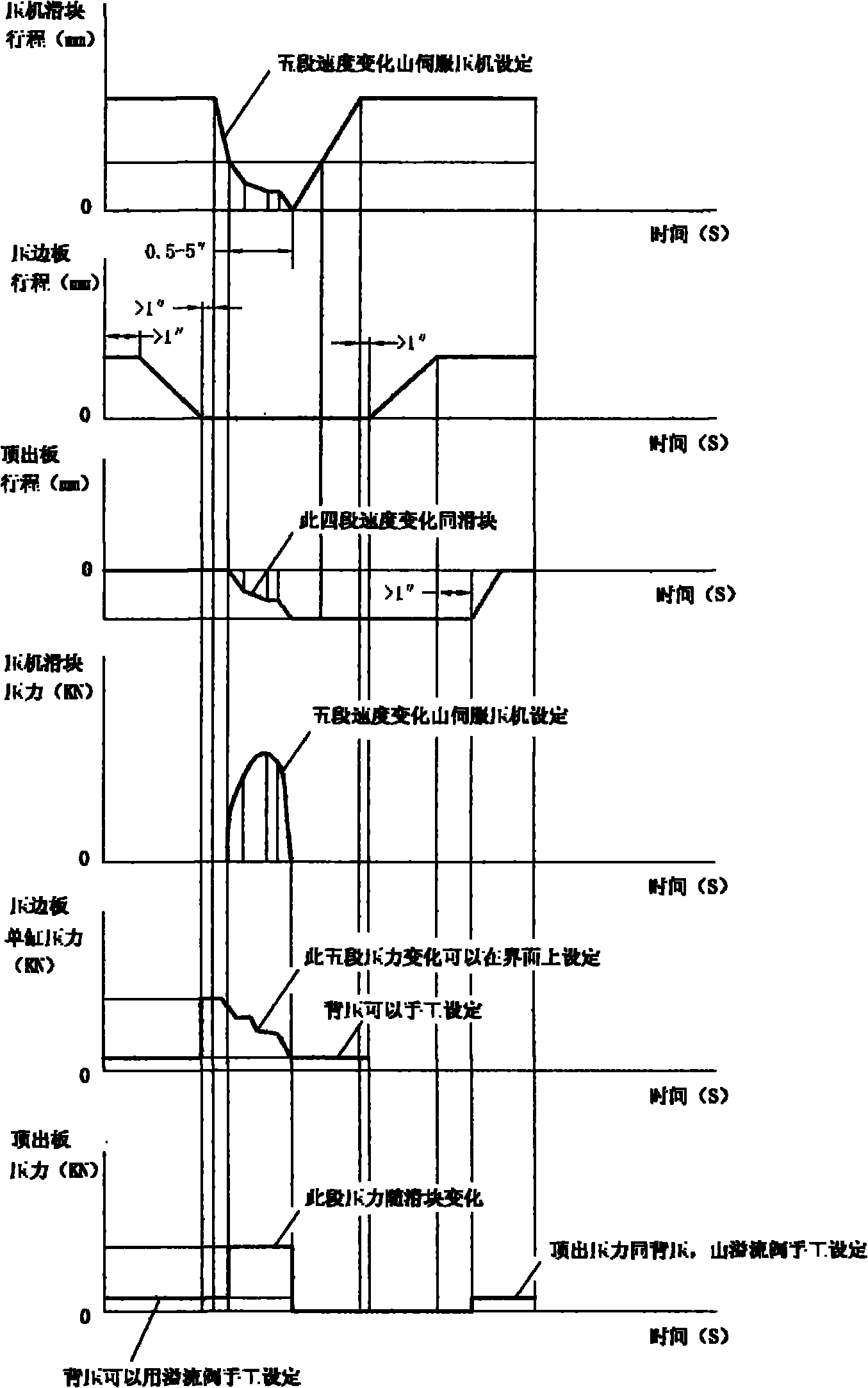

[0021] Such as figure 1 As shown, it is the structure of the positive edge blanking stamping die frame. The upper mold part includes the mold Bing 01, the upper template 02, the punch 22 and the punch backing plate 23, which are installed on the bottom surface of the slide block of the press and move with the slide block. According to the requirement of the guiding accuracy of the slider of the press, the guiding mechanism of the upper and lower molds of the mold can be set. The lower mold part is composed of the lower mold support plate 04, the blank holder 06, the lower template 07, the support column screw 03, the support column 05 and the ball guide column and guide sleeve. A blankholder hydraulic cylinder piston rod acts on the blankholder plate, and a blankholder force sensor is arranged on the piston rod. The anti-top plate 08 of the anti-top part is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com