Conveying equipment and conveying bent pipe thereof

A technology of bending pipes and inner pipes, which is applied in the field of conveying bends and conveying equipment with the conveying bends, can solve problems such as unstable quality of bends, prone to defects in casting, complicated manufacturing process, etc., to overcome the overall resistance Poor impact, shorten production cycle, improve overall strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

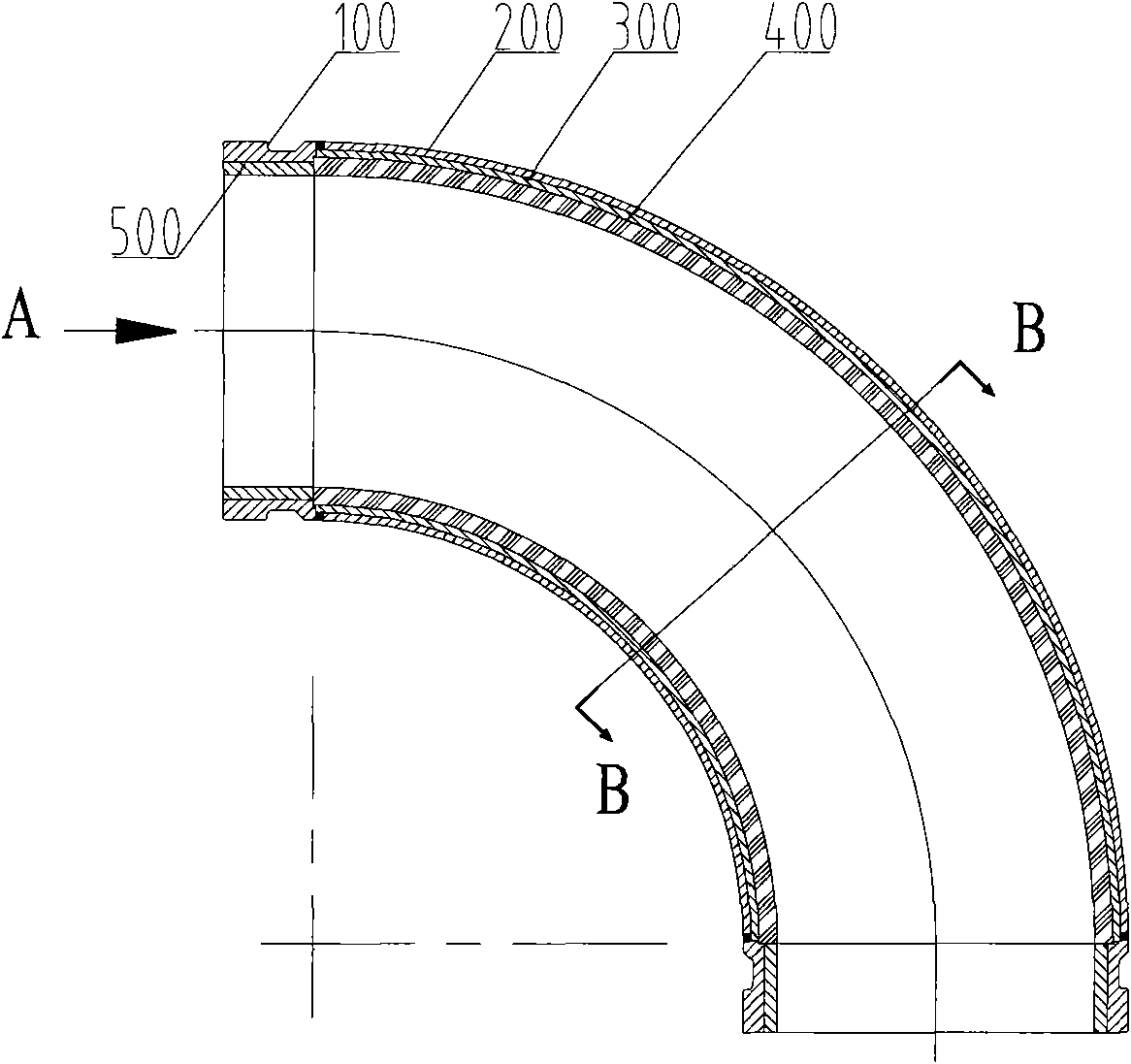

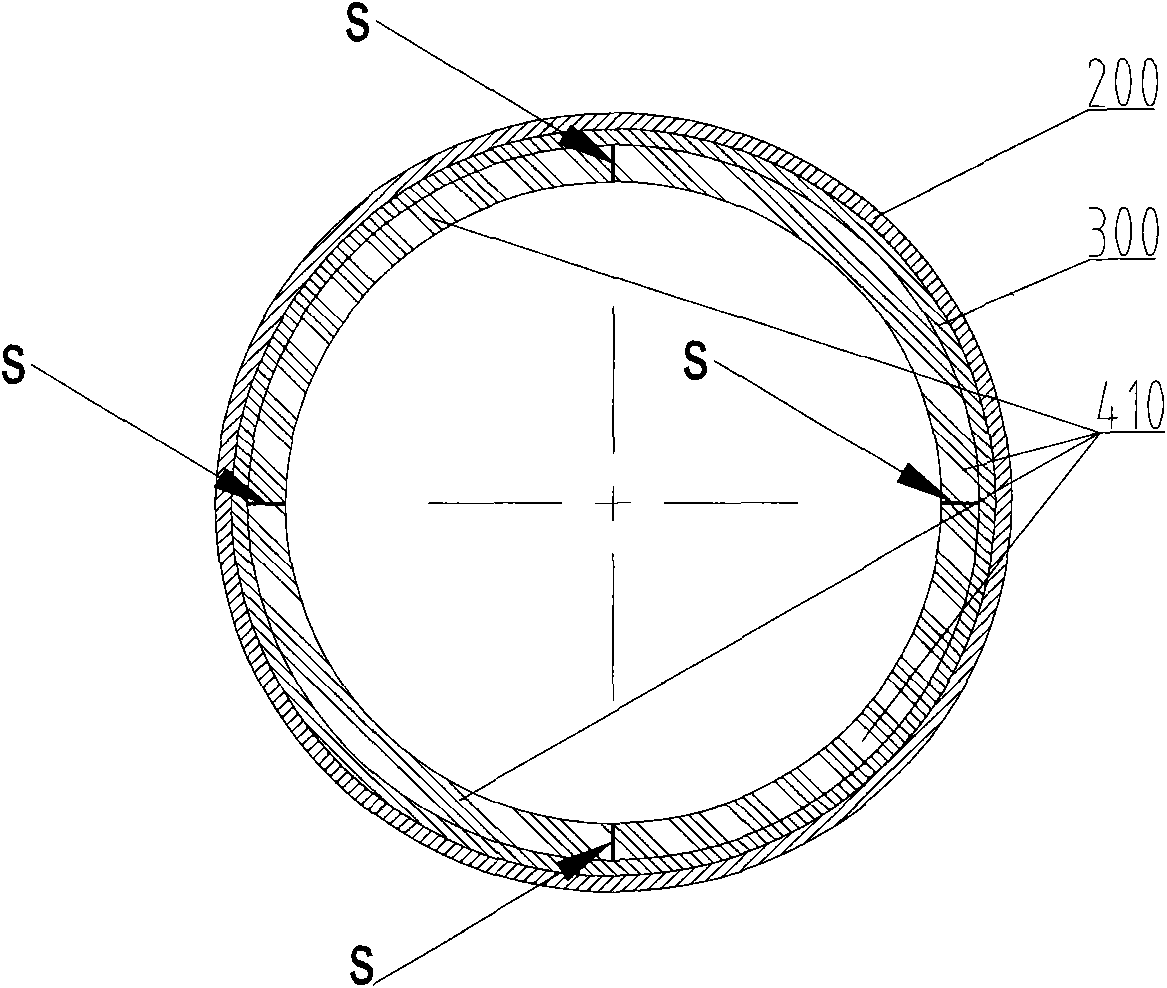

[0051] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. It should be noted that the conveying elbow provided in the present invention is not limited to conveying concrete, and can also be applied to conveying ash, other mud or other materials having similar properties to concrete mud.

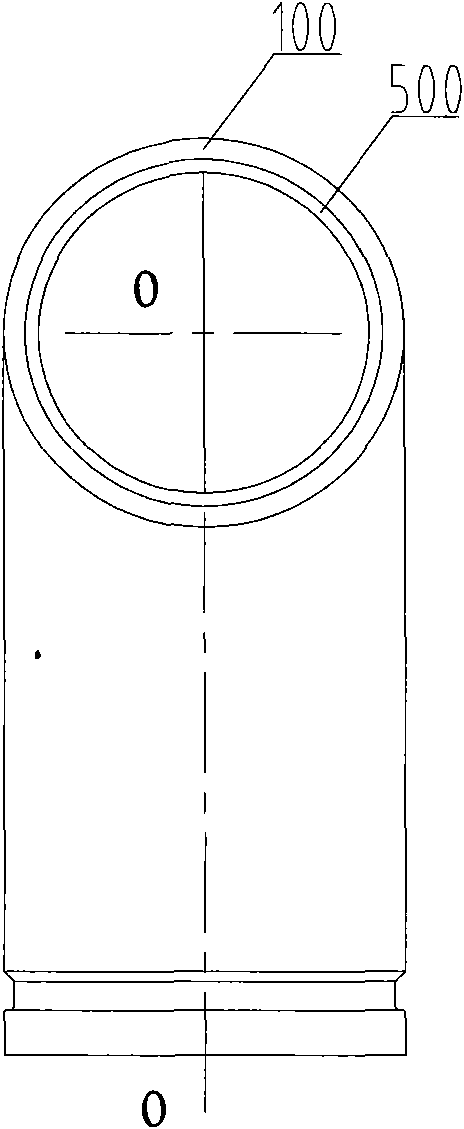

[0052] For the delivery elbow, the center line is a curve, and the curve is located in a longitudinal plane, for the convenience of description; in this application document, the section formed by cutting along a plane perpendicular to the curve is called a radial section, The section formed by cutting along the above-mentioned longitudinal plane is called a longitudinal section.

[0053] Please refer to figure 1 and figure 2 , figure 1 It is a schematic diagram of the longitudinal sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com