Arc reactor

A reactor, Anqi's technology, applied in the field of Anqi reactor, can solve the problems of increasing equipment cost and power consumption, limited reaction efficiency, large dead zone area, etc., to reduce reactor dead zone and enhance mass transfer effect , Improve the effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

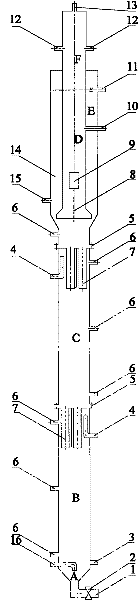

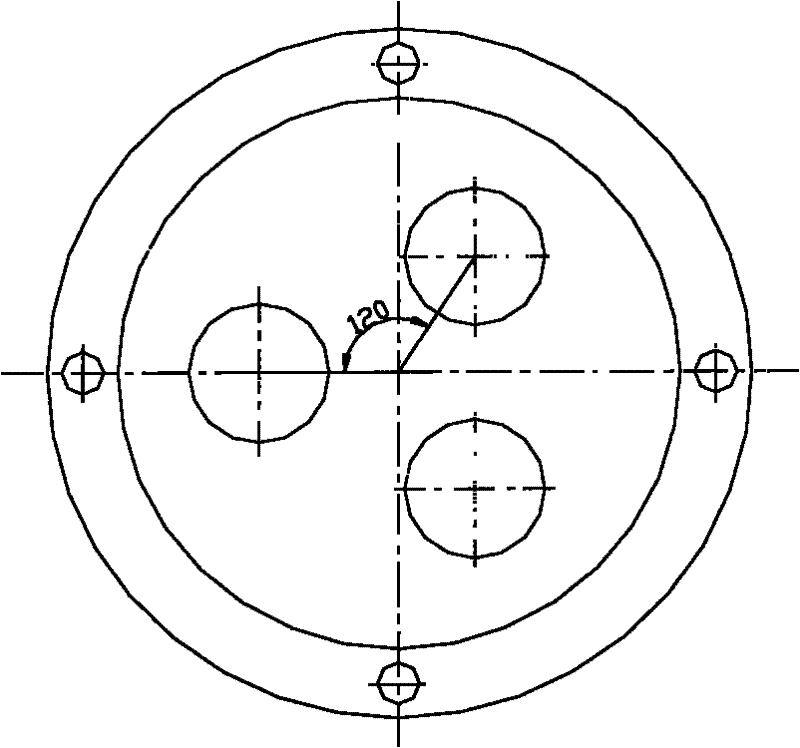

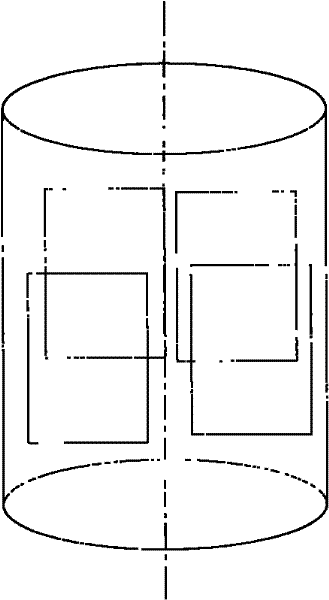

[0019] As shown in the figure, the main body of Anqi reactor includes water distribution area A, main reaction area, auxiliary reaction area D, precipitation area E and three-phase separation area F from bottom to top, and the main reaction area is divided into the first reaction chamber B) and the second reaction chamber C; the bottom of the water distribution area A is provided with a mud discharge pipe 1 and a valve 2, and the side wall of the water distribution area A is provided with a return water inlet pipe 3, a water inlet pipe 16 and a sampling port 6; the upper end of the first reaction chamber B A flange 5 is provided, a three-tube partition 7 is provided on the upper part of the first reaction chamber B, a sampling port 6 and an air stirring control pipe 4 are provided on the upper side wall of the first reaction chamber B, and a sampling port is provided on the side wall of the middle part of the first reaction chamber B. Port 6, the upper end of the second reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com