Concrete-based element mixing body

A technology of mixed element and concrete matrix, which is applied in the direction of building components, building insulation materials, buildings, etc., and can solve the problems of poor high temperature resistance, inability to withstand high temperature flue gas, and poor waterproof effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

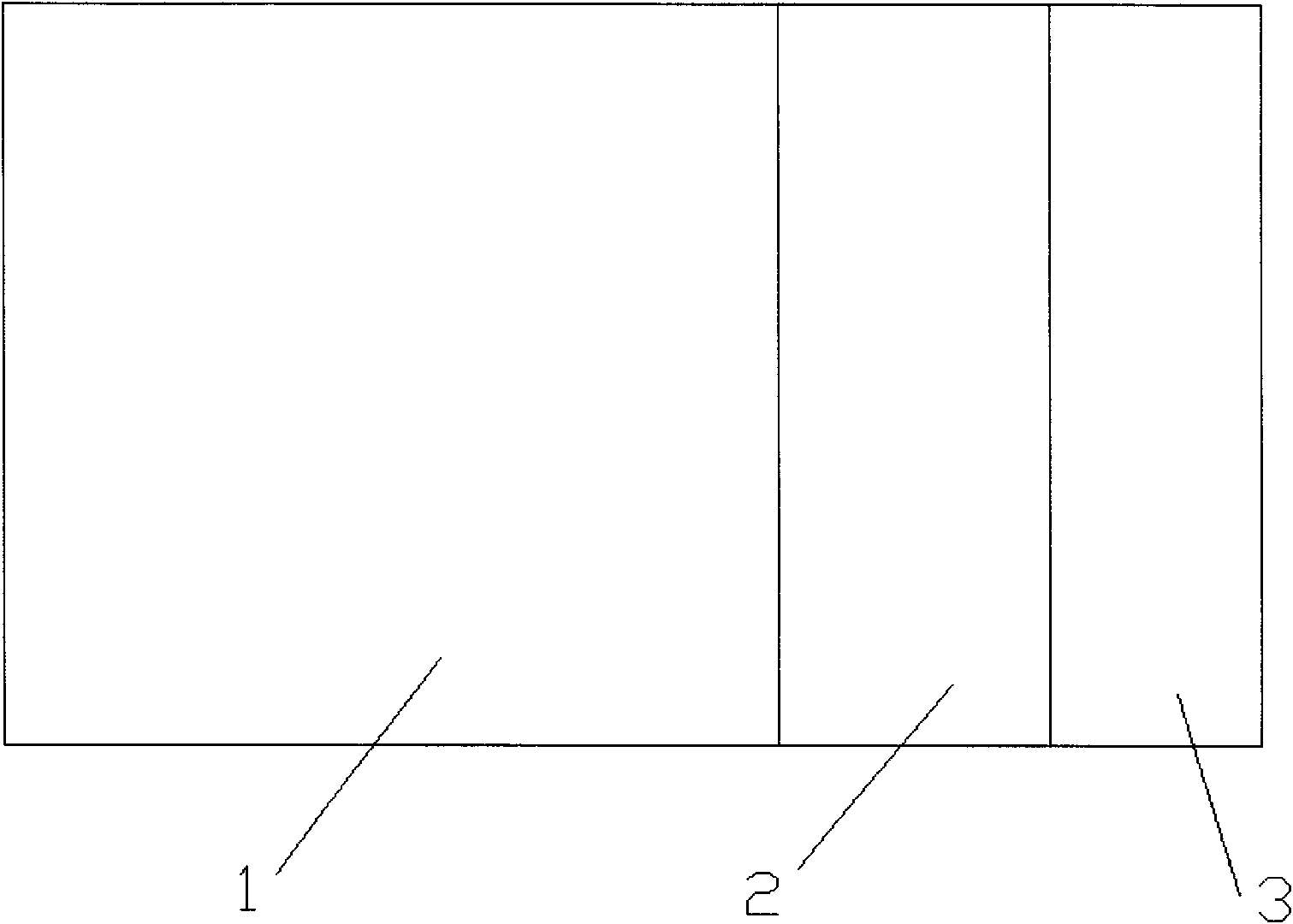

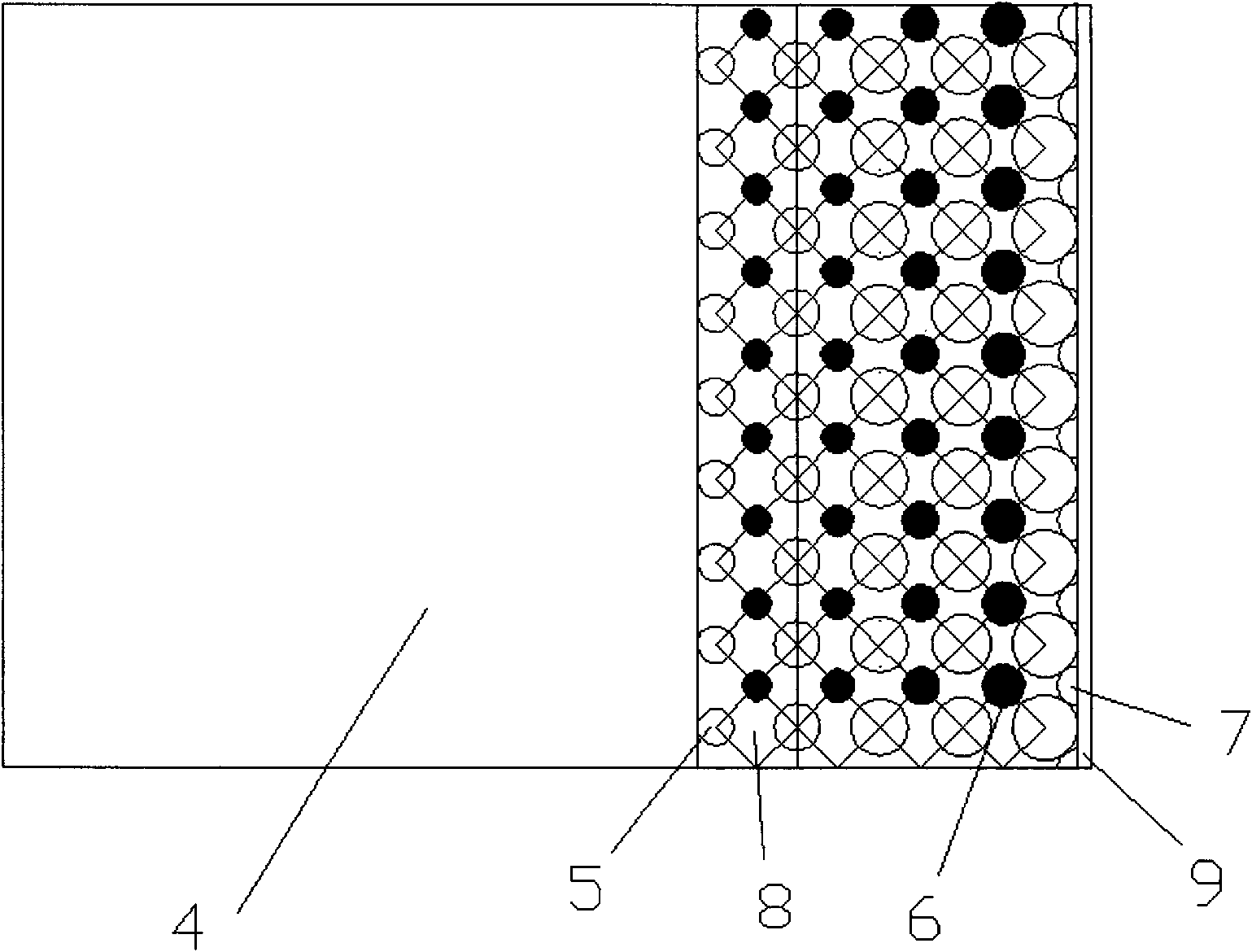

[0022] as attached figure 1 As shown, the untreated concrete matrix includes concrete tough layer 1, concrete pulverization layer 2 and floating ash and corrosion pulverization layer 3, while the concrete base-mixed body includes concrete matrix 4, reducing agent 5, reinforcing agent 6. Repairing agent 7, toughening agent 8, glaze agent 9, see attached figure 2 . The whole concrete base-mixed body is a mixed body formed by the combination of the main body integrating reduction, reinforcement, repair and toughening, and the glazed protective reinforcement surface, forming an impermeable, temperature-resistant, acid-resistant, A chemical molecular chain structure that is resistant to wear, stretch, and thermal shock. This main body reticulates in the temperature range of ≤250°C.

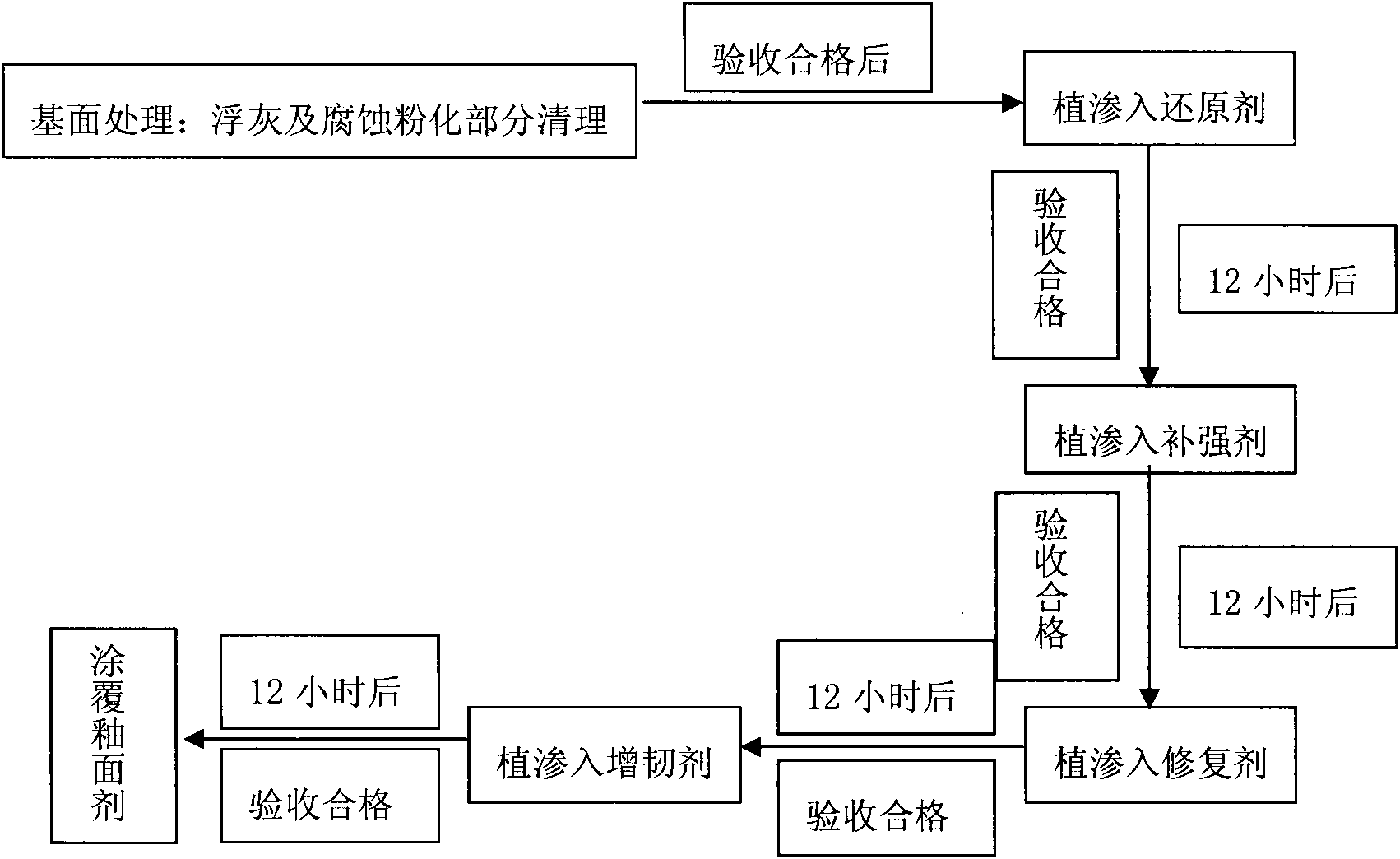

[0023] as attached image 3 As shown, the construction process of the concrete-based ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com