Organic anti-freeze cooling liquid and preparation method thereof

An anti-freezing coolant, organic technology, applied in the field of automotive coolant, can solve the problems of insufficient amount of antioxidants, consumption of antioxidants, etc., and achieve the effects of good market prospects, low production costs, and less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with specific embodiments.

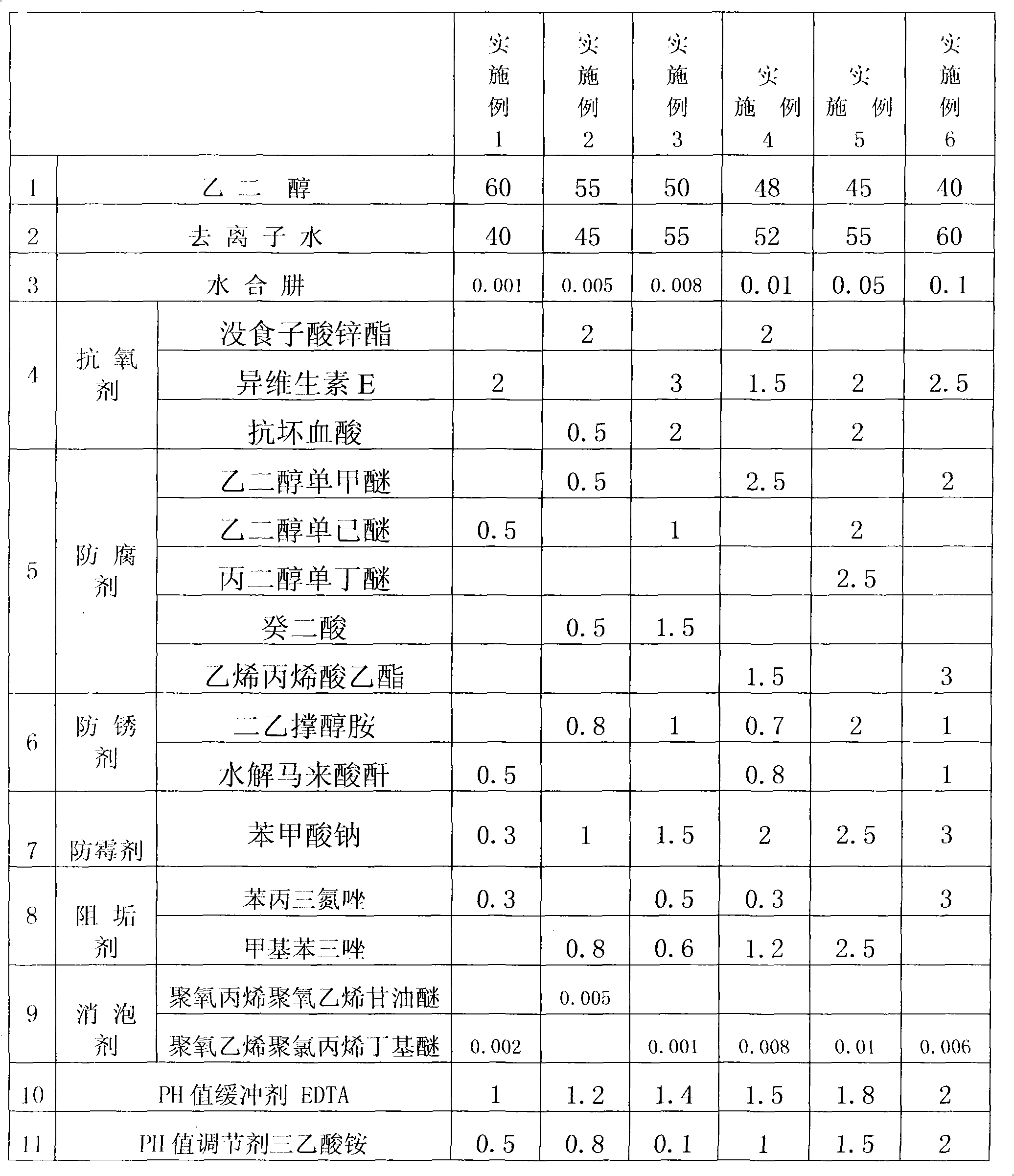

[0042] The basic component of antifreeze coolant is ethylene glycol, the amount of ethylene glycol determines the grade of antifreeze coolant, the second main component is deionized water, deionized water contains free oxygen, free oxygen is destructive, one of the technical characteristics of the present invention It is to add a reducing agent to change deionized water into deionized oxygen-free water. The amount of additives is related to the amount of deionized water. The preparation process is mainly to deal with free oxygen in deionized water. It is operated under normal pressure, heated to boiling, added, stirred, Make it fully dissolve, and the quantity of materials used in each embodiment in Table 1 has been in kg.

[0043] Table 1

[0044]

[0045] Reactor A is a closed container with stirring, heating, cooling and testing equipment attached to reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com