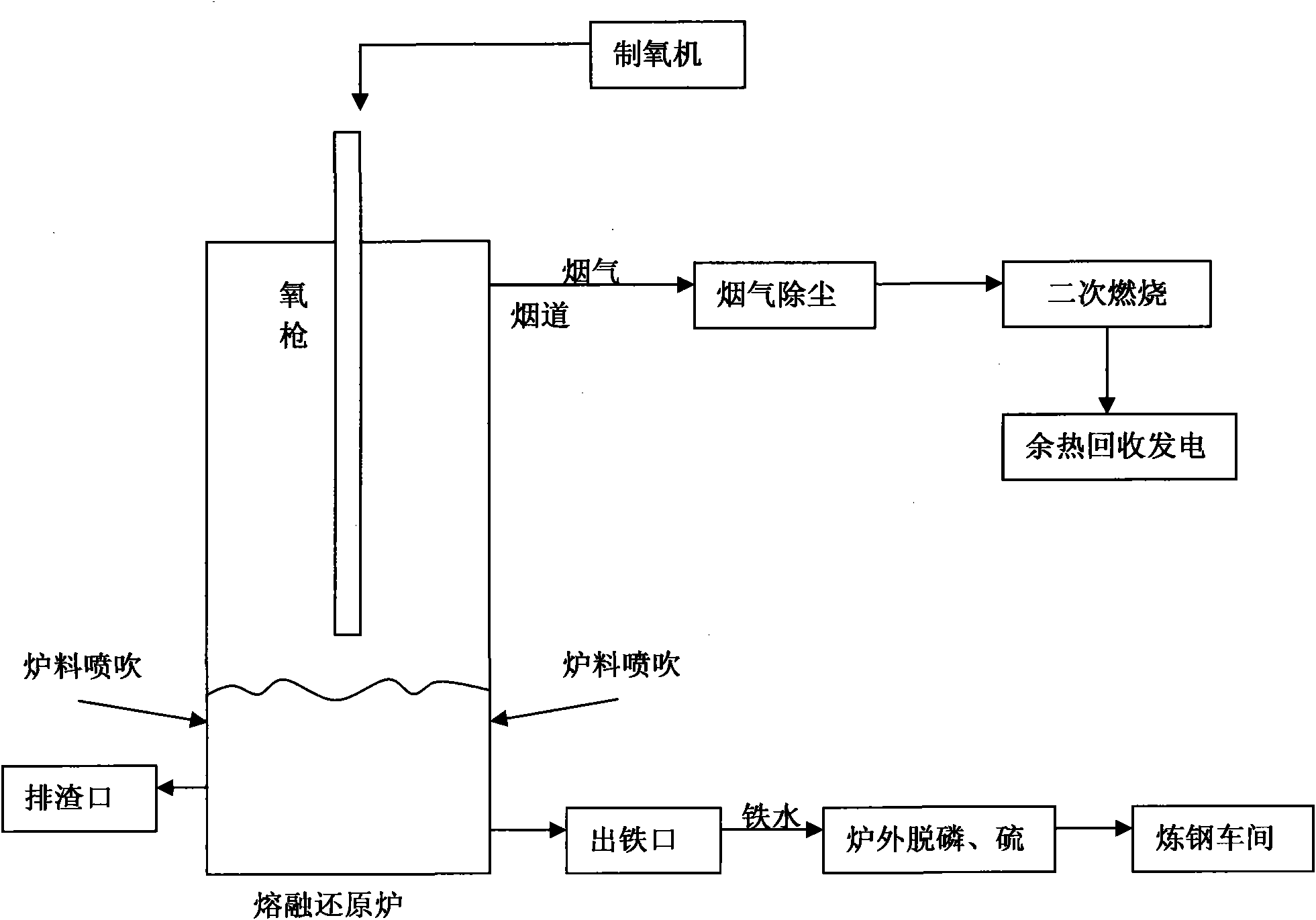

Method for producing low-phosphorus molten iron by utilizing oxygen-enriched top blown to carry out melting reduction on high-phosphorus iron ore

A technology of oxygen-enriched top-blowing and high-phosphorus iron ore, applied in the field of energy and metallurgy, can solve the problems of heavy pollution, low thermal efficiency, and high energy consumption of blast furnace ironmaking technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

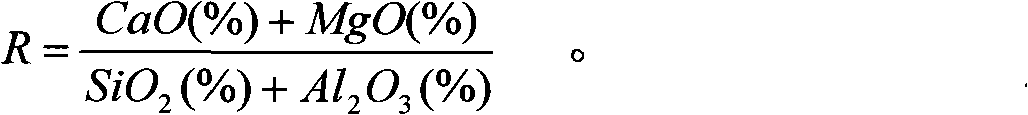

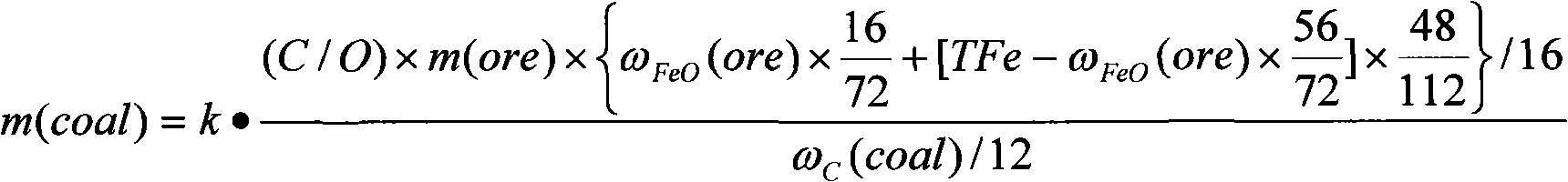

[0062] Example 1 Huimin iron ore (TFe (%) = 49.01, FeO (%) = 1.36, SiO 2 (%)=18.99, Al 2 o 3 (%)=5.81, MgO(%)=0.23, CaO(%)=0.36, TiO 2 (%) = 0.28, S (%) = 0.038, P (%) = 0.90), flux and coal (C (%) = 76.43, ash (%) = 15.29, volatile matter (%) = 7.78, CaO (%) )=1.59, SiO 2 (%)=7.80, S (%)=0.35, P (%)=0.050) powder crushing (≤30mm), be 1.1 according to basicity, carbon ratio C / O is 1.1 process parameter proportioning mixing, by Furnace side injection enters the smelting reduction furnace, the furnace temperature is controlled at 1450°C, and the molten iron results obtained under the condition of oxygen-enriched top blowing: the recovery rate of iron reaches about 86.8%, the phosphorus content in pig iron is 0.32%, and the sulfur content is 0.1645 %, because the content of sulfur and phosphorus is still high, so the remaining oxidative atmosphere is used to continue the dephosphorization outside the furnace after the molten iron is released. The models of oxygen-enriched an...

Embodiment 2

[0063] Example 2 The above raw materials are the same, according to the basicity of 1.1, the carbon ratio C / O is 1.1, the process parameters are mixed evenly, sprayed into the smelting reduction furnace from the side of the furnace, and the furnace temperature is controlled at 1400 ° C. The result of molten iron under blowing conditions: the recovery rate of iron reaches about 84.3%, the phosphorus content in pig iron is 0.23%, and the sulfur content is 0.07%. According to the requirements for molten iron, it is decided whether to carry out dephosphorization and desulfurization outside the furnace, and then sent to Steel workshop.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com