Hydraulic high-efficiency water-saving toilet stool

A hydraulic and high-efficiency technology, applied in water supply devices, flushing equipment with water tanks, buildings, etc., can solve problems such as difficult to clean, fiber accumulation, difficult to clean, etc., to achieve high comprehensive water saving efficiency, comprehensive cost performance, and applicability broad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

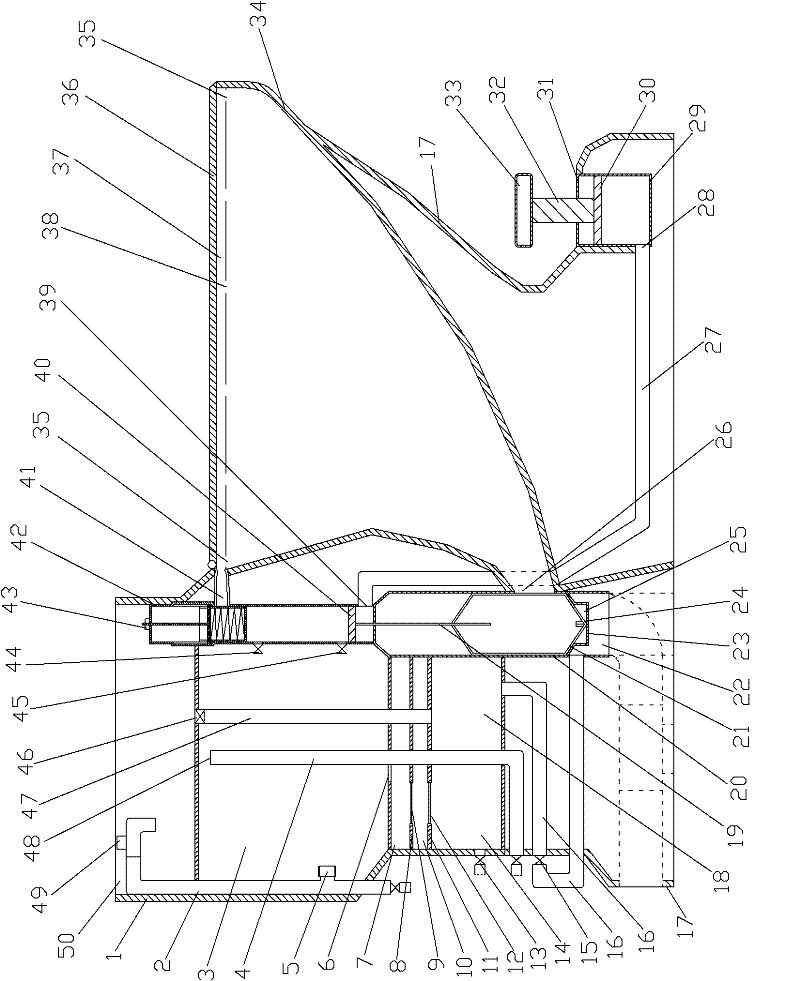

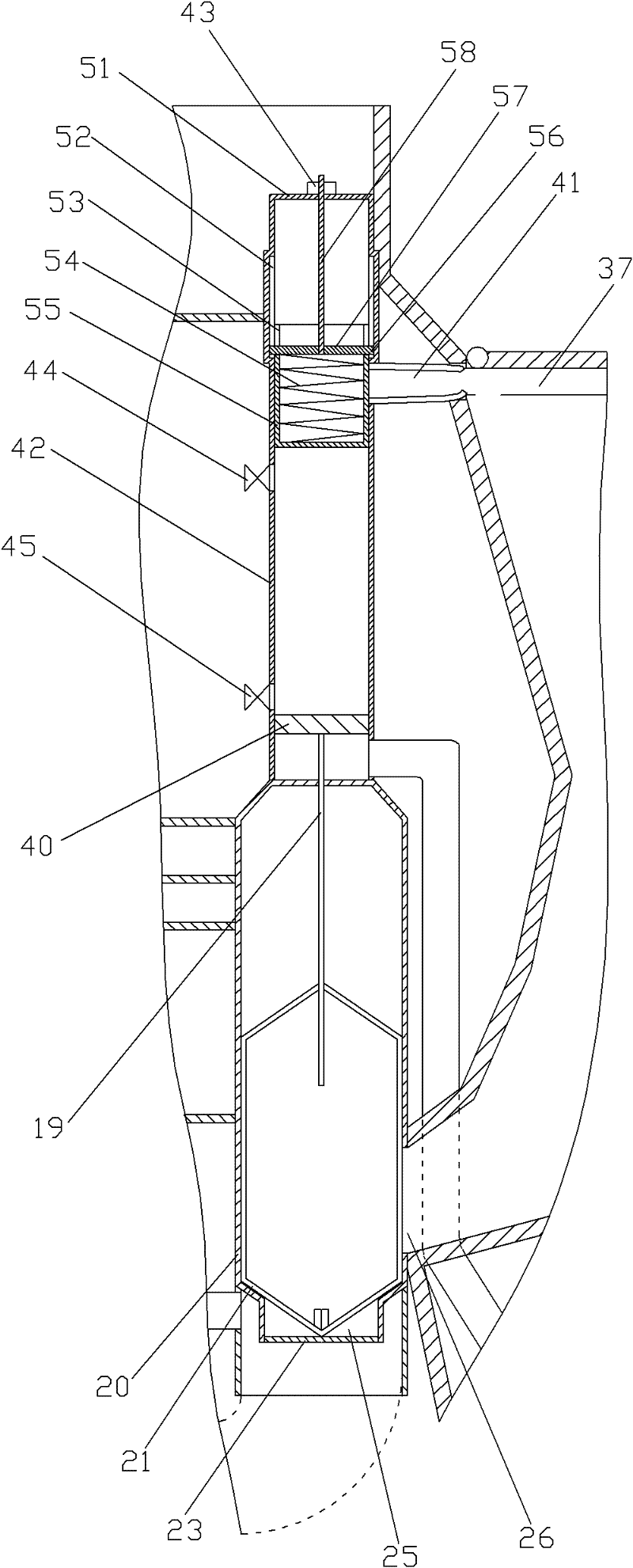

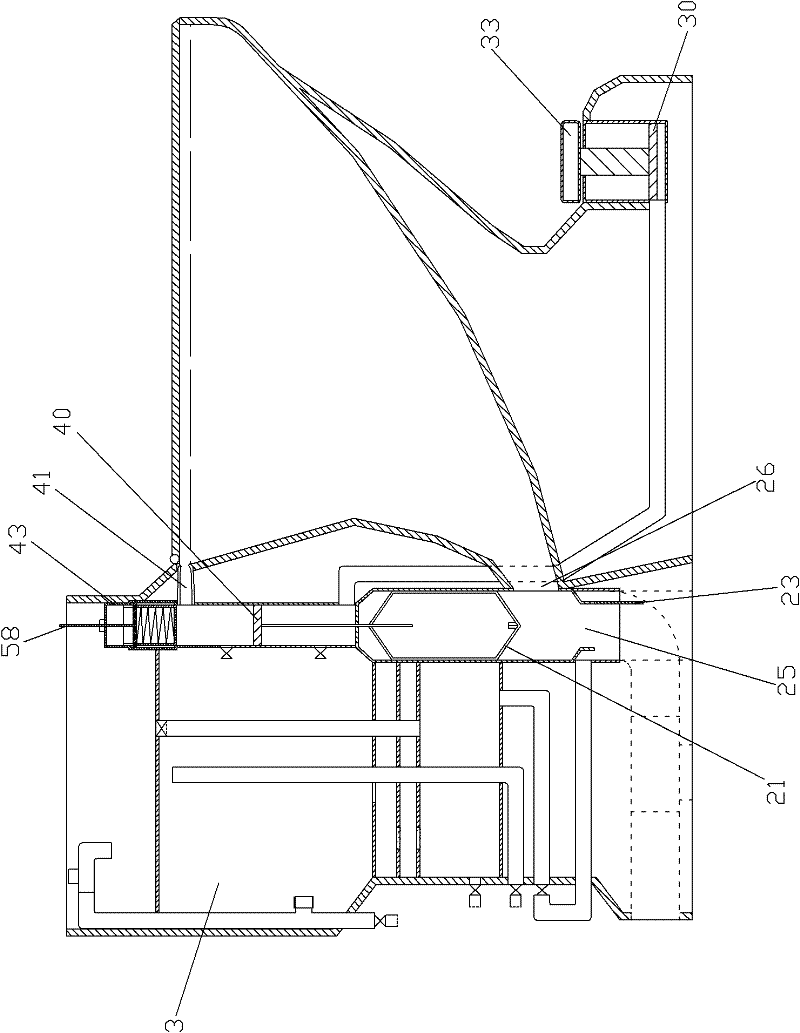

[0030] Such as Figure 1 to Figure 3 As shown, the hydraulic high-efficiency water-saving toilet of the present invention includes a main body system, a water tank system, and a spray washing system. The main system includes a base 17, a casing 1 and a urinal 34. The water tank system includes a washbasin 50, a water storage tank 3, and a water quality treatment tank 18. The spray system includes a water-saving spray wash device, a sewage intercepting device, and a pedal hydraulic device.

[0031] The base 17 is located at the bottom of the main system, and it is roughly composed of two parts, the front and rear seats. The base 17 is the main fixed support of the main system. The box body 1 is located at the rear and upper part of the base 17. The important part of the closet, the urinal is located at the front top of the base 17 and the front end of the casing 1, the urinal 34 is shaped like a crooked funnel, and the urinal 34 is connected with a corresponding urinal cover 36...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com