Rotation speed synchronizing signal-based spark plug sparking control device

A speed synchronization signal and control device technology, applied in the direction of automatic control, automatic control, electrical automatic control, etc., can solve problems such as adverse effects on engine performance, impact on spark plug service life, spark-over timing angle error, etc., and achieve great practical significance in production , Avoid invalid flashover, high ignition success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be described below in conjunction with the accompanying drawings and embodiments.

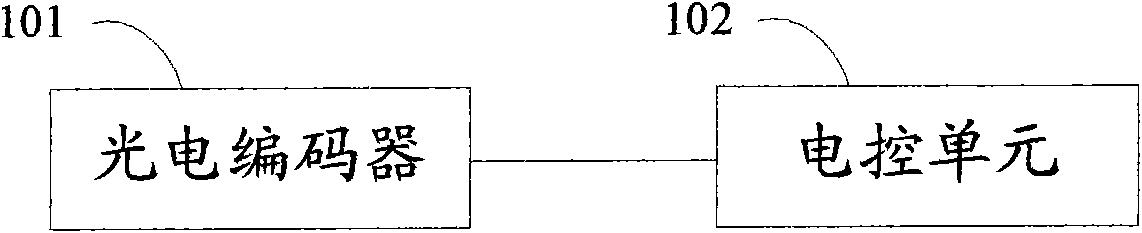

[0027] figure 1 An overall structural diagram of a spark plug flashover control device based on a rotational speed synchronization signal provided by the present invention.

[0028] see figure 1 , the present invention provides a spark plug flashover control device based on a speed synchronization signal, the device includes a photoelectric encoder 101 and an electronic control unit 102, wherein:

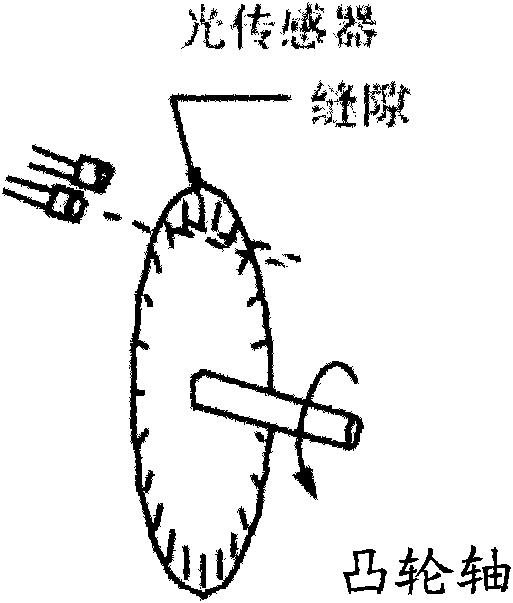

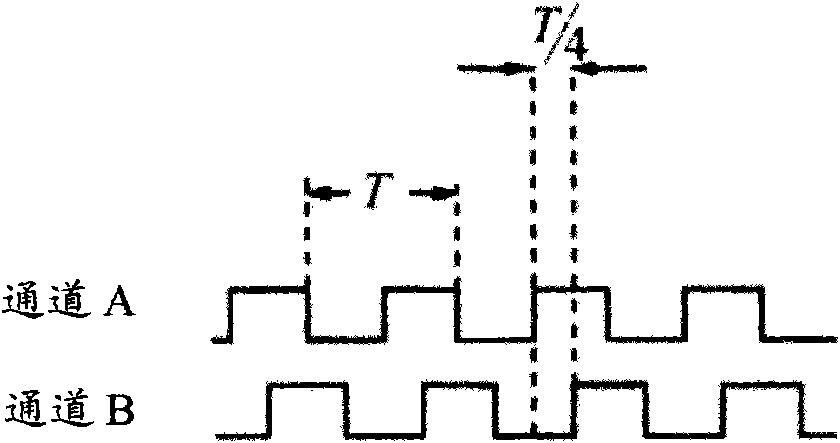

[0029] Photoelectric encoder 101, it is installed on the camshaft of engine, is used for the speed synchronous signal of real-time acquisition engine and top dead center signal and outputs to electric control unit 102 (being single-chip microcomputer);

[0030] The electronic control unit 102 is connected with the photoelectric encoder 101, and is used to realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com