Optical fiber loop for optical fiber gyroscope

An optical fiber loop and fiber optic gyroscope technology, which is used in Sagnac effect gyroscopes, gyroscopes/steering sensing equipment, optics, etc. The coil quality is difficult to achieve consistency and stability, affecting the mass production of fiber optic gyroscope products, etc., to achieve the effects of improving geometric control accuracy, performance indicators, winding efficiency, and control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

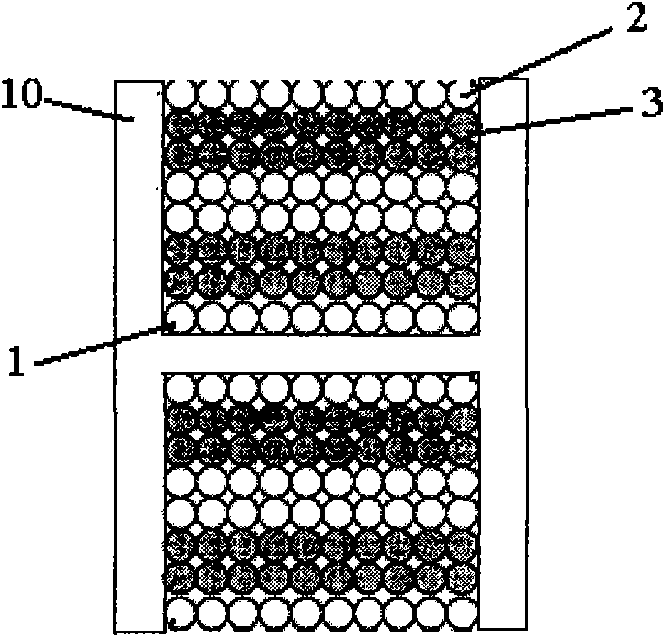

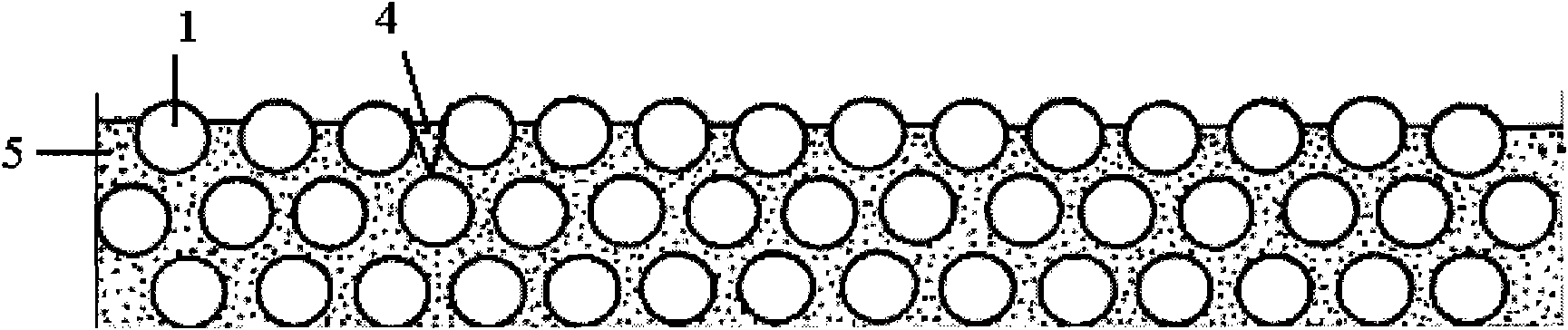

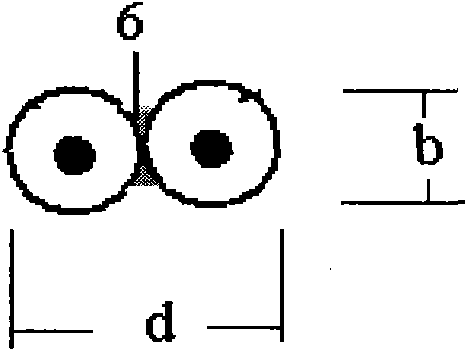

[0026] Two polarization-maintaining optical fibers 1 of the same type are bonded side by side with resin and cured by ultraviolet light to form a dual-core polarization-maintaining optical fiber ribbon 6. Half to another identical optical fiber reel, thereby obtaining the midpoint 9 of this one and band optical fiber ribbon, this midpoint is exactly the symmetrical midpoint needed when winding the ring, and the winding of the coil starts from this midpoint . Using the quadrupole winding method, starting from the symmetrical midpoint, the optical fiber ribbons on the two fiber distribution discs are wound onto the sensing skeleton 10 in sequence, Figure 4 and Figure 5 The key steps of the quadrupole winding method are given. The dual-core polarization-maintaining optical fiber ribbon 6 is equally divided into left and right sections and wound on the left and right fiber splitters 7 and 8, and the midpoint of the optical fiber ribbon is 9 in the figure. Then the reel-shaped...

Embodiment 2-8

[0029] In Embodiment 2-8, the same parallel structure design is adopted, and the quadrupole symmetrical winding method is also used to wind the optical fiber ring, and the parameters of the parallel tape, the parameters of the ring skeleton and the parameters of the optical fiber ring after winding are See Table 1 for polarization crosstalk parameters. Wherein the full text measurement condition is identical with embodiment 1.

[0030] Table 1: Parallel parameters, ring bobbin parameters, and polarization crosstalk parameters of the fiber ring after winding

[0031]

[0032] It can be seen from Table 1 that, using the polarization-maintaining optical fiber ribbon of the present invention to wind the optical fiber ring, the crosstalk at room temperature remains quite stable, and at the same time, the crosstalk at full temperature varies around 3dB, and the distribution is concentrated. It shows that the optical fiber loops wound by the polarization-maintaining optical fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com