Hybrid minitype super capacitor based on organic electrolyte and manufacturing method thereof

An organic electrolyte and supercapacitor technology, applied in the field of MEMS, can solve the problems of reducing micro supercapacitors and no solutions have been proposed, and achieve the effect of improving energy storage characteristics and reducing internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

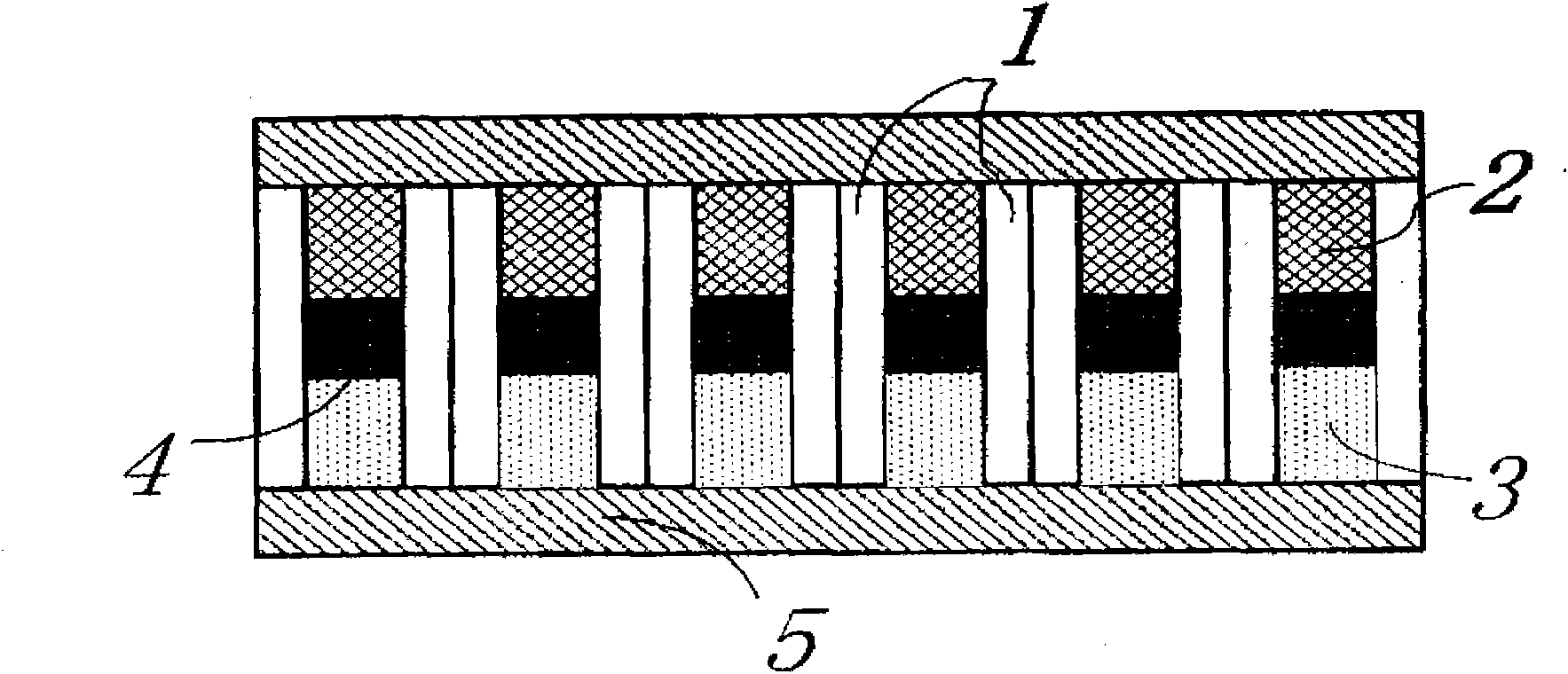

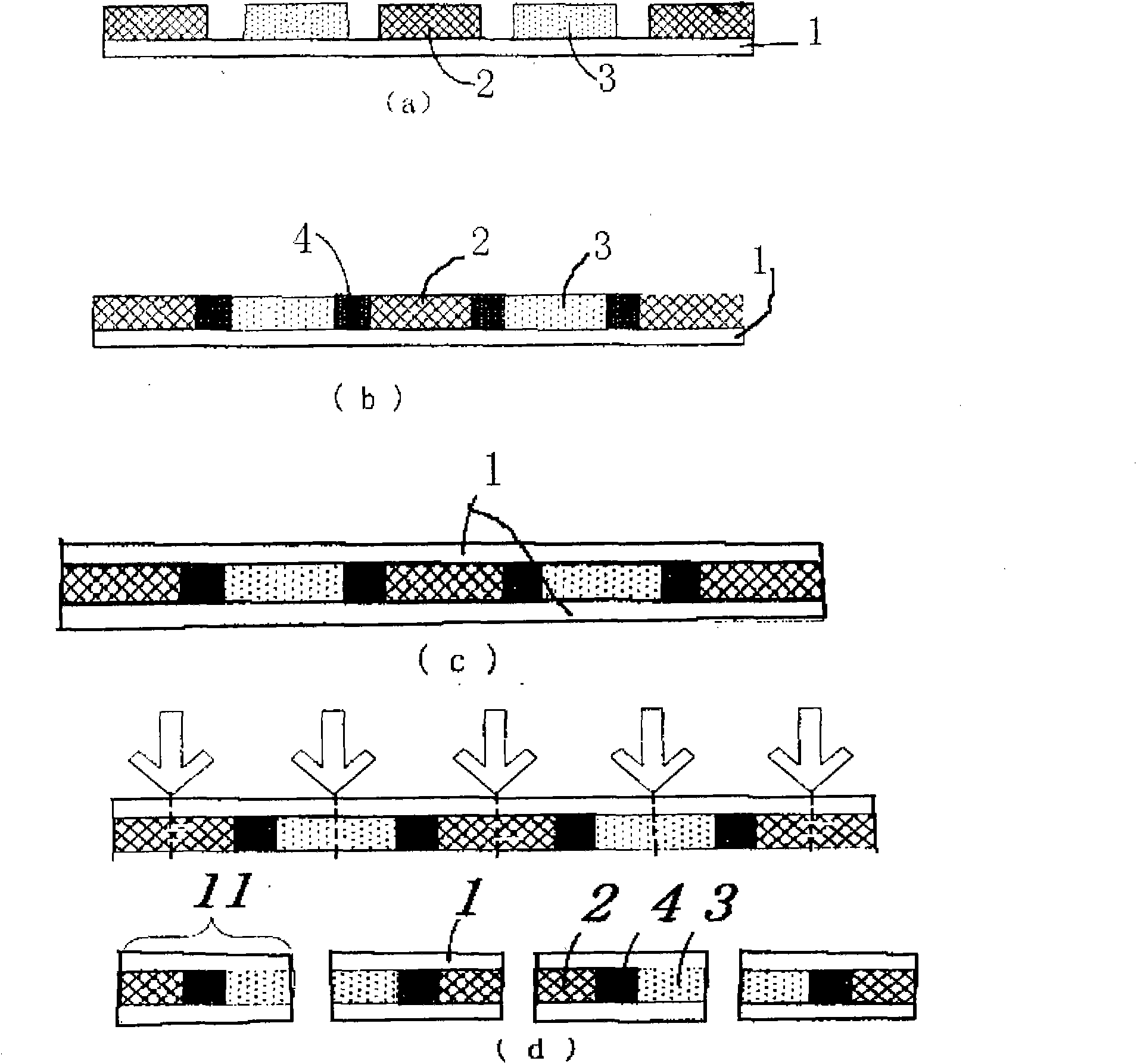

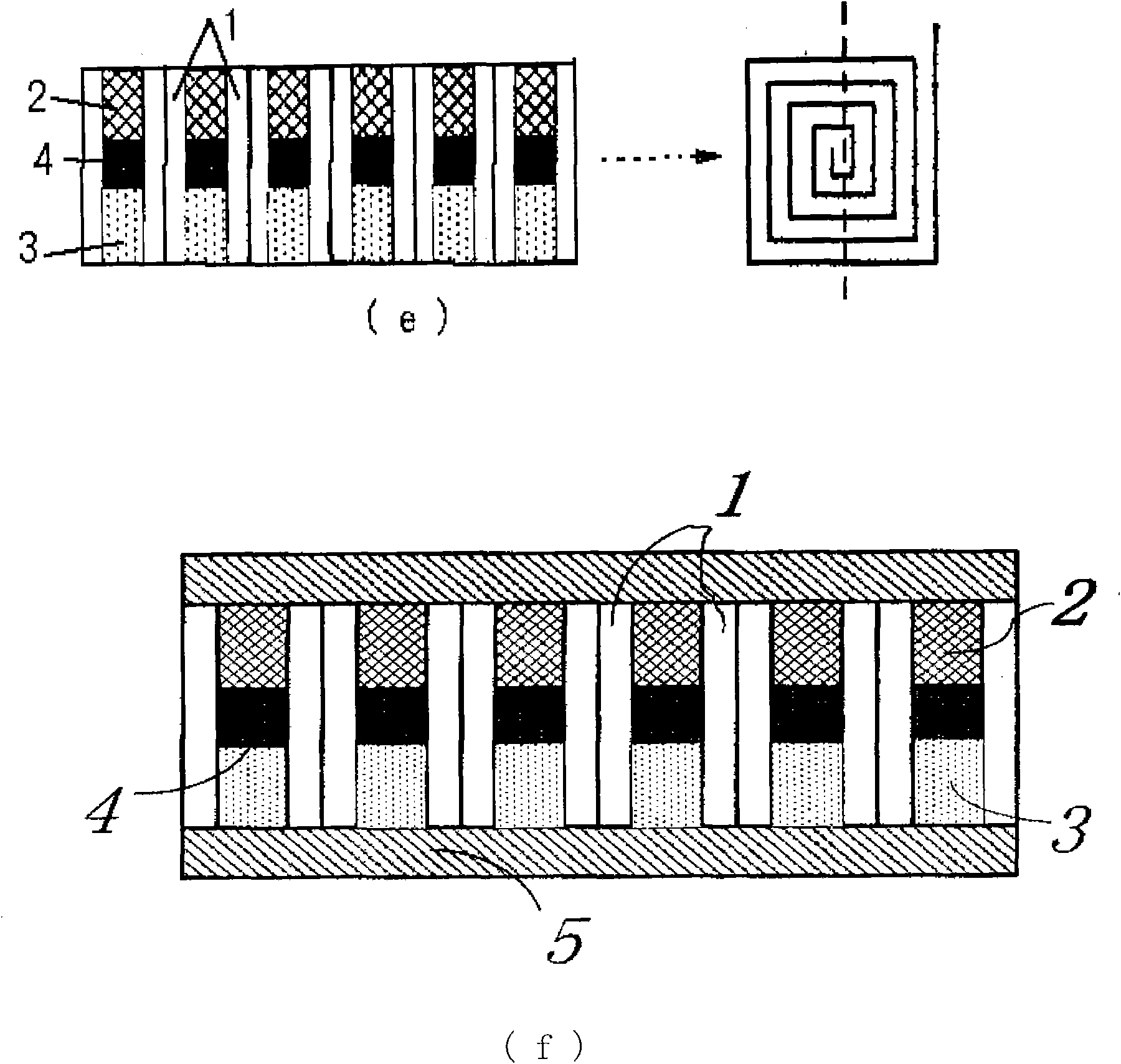

[0012] The invention provides a hybrid micro supercapacitor based on an organic electrolyte and a manufacturing method thereof. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0013] figure 1 It is a schematic diagram of the composition and structure of a hybrid micro-supercapacitor based on an organic electrolyte. The micro supercapacitor is composed of two polyimide substrates 1, and the positive electrode 2, separator 4 and negative electrode 3 are arranged vertically from top to bottom to form a unit; multiple units are connected to each other and wound into a cylinder, aluminum The caps 5 are respectively covered on both ends of the cylinder, and the positive electrode 2, the negative electrode 3 and the separator 4 are impregnated with an organic electrolyte solution, and the positive electrode 2 and the negative electrode 3 are respectively drawn from both ends, and at the same time serve as a current ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com