Smoke power-type wet desulphurization ultrasonic atomization device and application thereof

A wet desulfurization and atomization device technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of high desulfurization cost, large number of nozzles, poor nozzle atomization effect, etc., and improve desulfurization efficiency. , to avoid the slurry staying or clogging, to avoid the effect of erosion and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

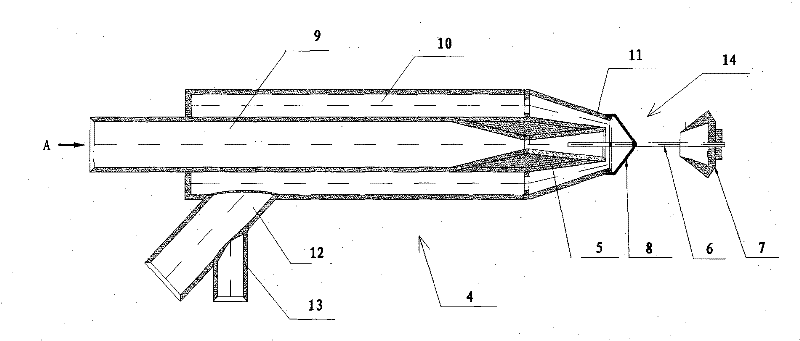

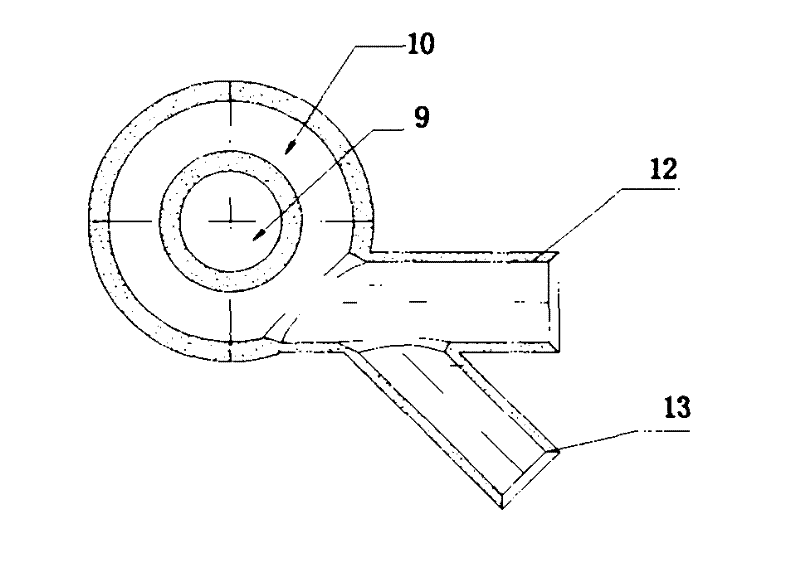

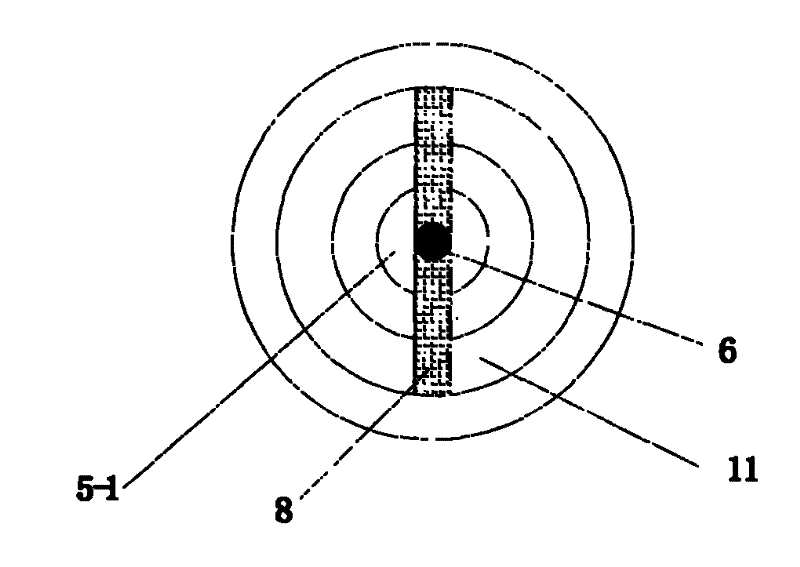

[0027] Such as figure 1 As shown, the flue gas dynamic wet desulfurization ultrasonic atomization device of the present invention includes a nozzle body 4 and a resonance cavity 7. The resonance cavity 7 is arranged at the front end of the nozzle body 4 through a central rod 6. The nozzle body 4 includes a flue gas channel 9. The slurry channel 10. The slurry refers to the limestone slurry. The flue gas channel 9 and the slurry channel 10 are cylindrical tubular structures. The slurry channel 10 is set outside the flue gas channel 9. The distance between them is about 5mm, and the outlet of the flue gas channel 9 is a venturi tube 5, which can reduce the resistance of the flue gas in the flue gas channel 9, and make the flue gas fully expand to supersonic speed. The outlet 11 of the slurry channel 10 is a tapered constriction, one end of the central rod 6 extends into the outlet of the Venturi tube 5 , and the middle part of the central rod 6 is fixedly connected with the nozz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com