Preparation process of sputtering tantalum ring

A preparation process and tantalum ring technology are applied in the field of preparation technology of sputtered tantalum rings, which can solve the problems of increased processing difficulty of sputtered tantalum rings, and achieve the effects of low processing difficulty, high processing efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

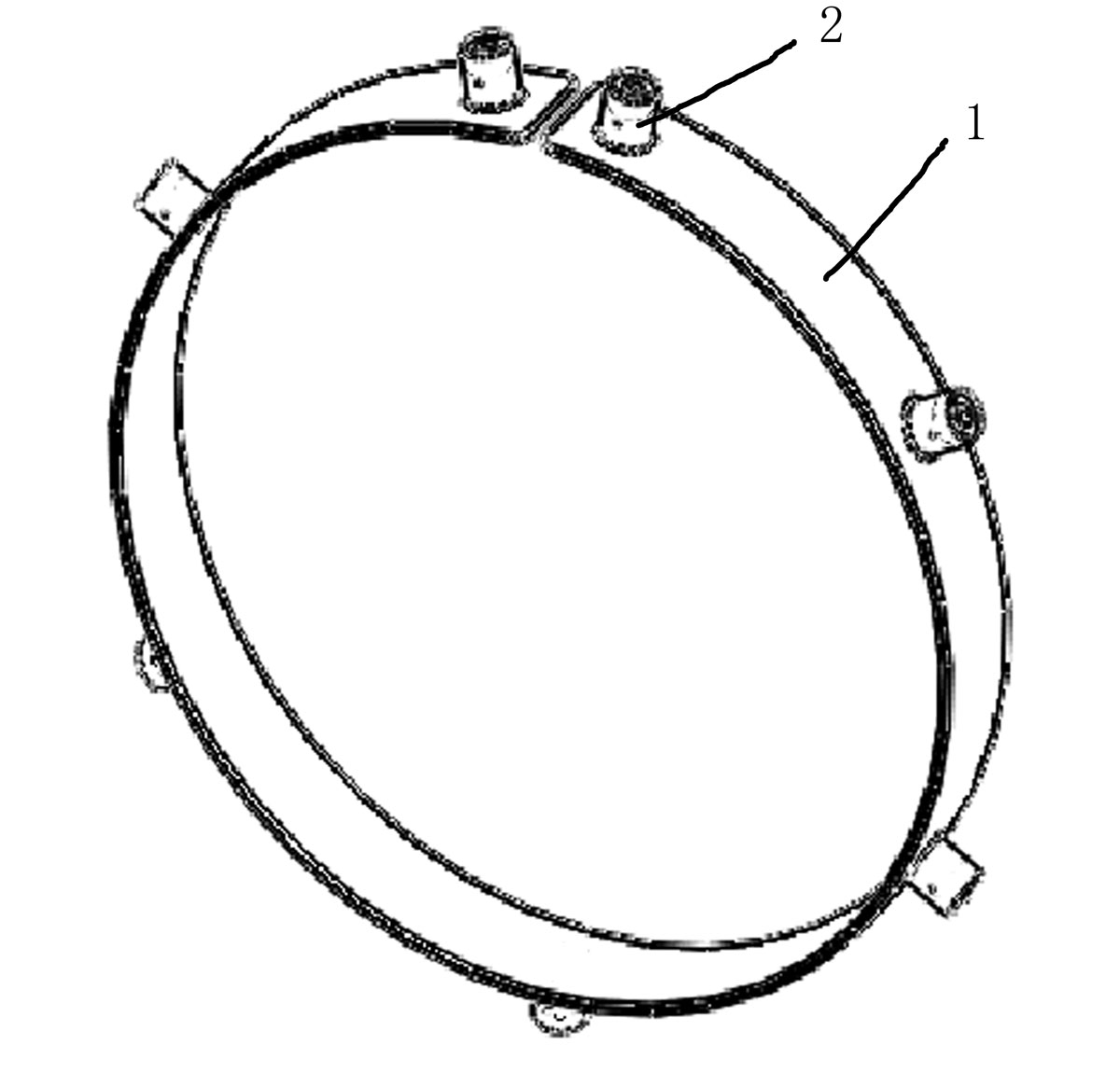

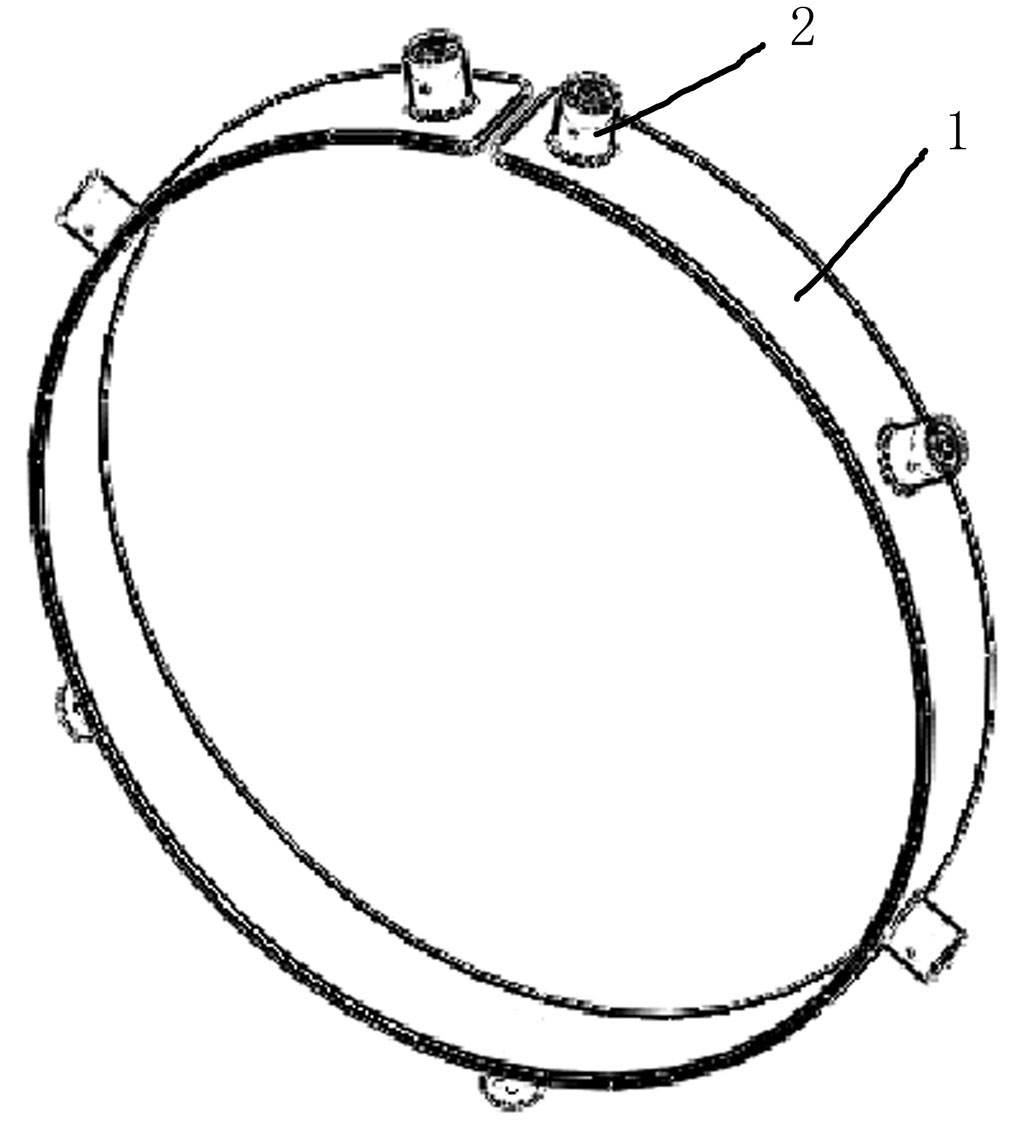

Image

Examples

Embodiment Construction

[0025] The preparation process steps of sputtering tantalum ring of the present invention are:

[0026] 1. The ring is made of tantalum bars

[0027] The grain size is required to meet the product requirements, and the same board difference and surface quality meet the requirements of subsequent processing. The specific process can be used:

[0028] First of all, forging is carried out in the way of square first and then flattening, with a total processing rate of 65% to 75%; the first heat treatment is carried out at a temperature of 1000°C to 1100°C for 60min to 120min; The total processing rate is 70% to 80%; the second heat treatment is carried out at 1000°C to 1100°C for 60min to 120min; the finished product is rolled by unidirectional rolling, and the total processing rate is 70% to 80%. %; Under the temperature condition of 1200℃~1400℃, the third heat treatment is carried out for 120min~180min; leveling and blanking, and the preparation of tantalum strips is completed....

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com