Integrated monitoring ring device of machine tool spindle

A technology of machine tool spindle and monitoring ring, used in measuring/indicating equipment, metal processing mechanical parts, metal processing equipment, etc., can solve problems such as distortion and vibration signal attenuation, reduce test signal attenuation and distortion, and improve integration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

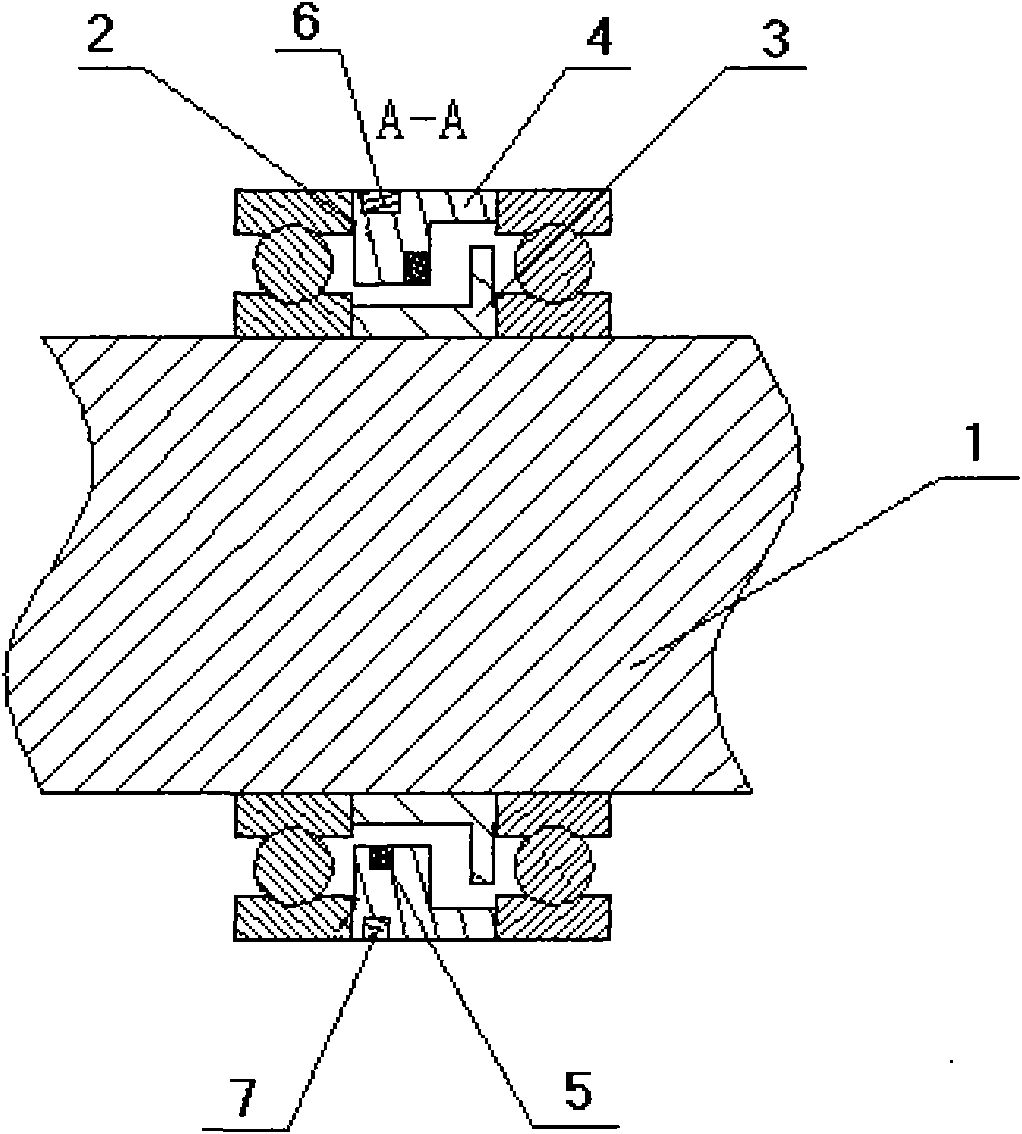

[0020] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

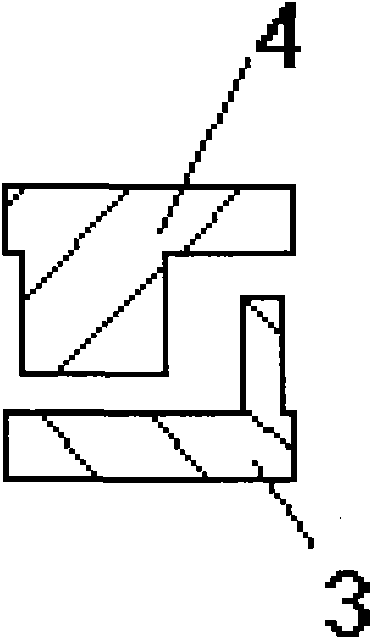

[0021] refer to figure 1 , one A machine tool spindle integrated monitoring ring device includes an angular contact bearing 2 supporting a spindle 1, and an inner ring spacer 3 and an outer ring spacer 4 are arranged in the angular contact bearing 2.

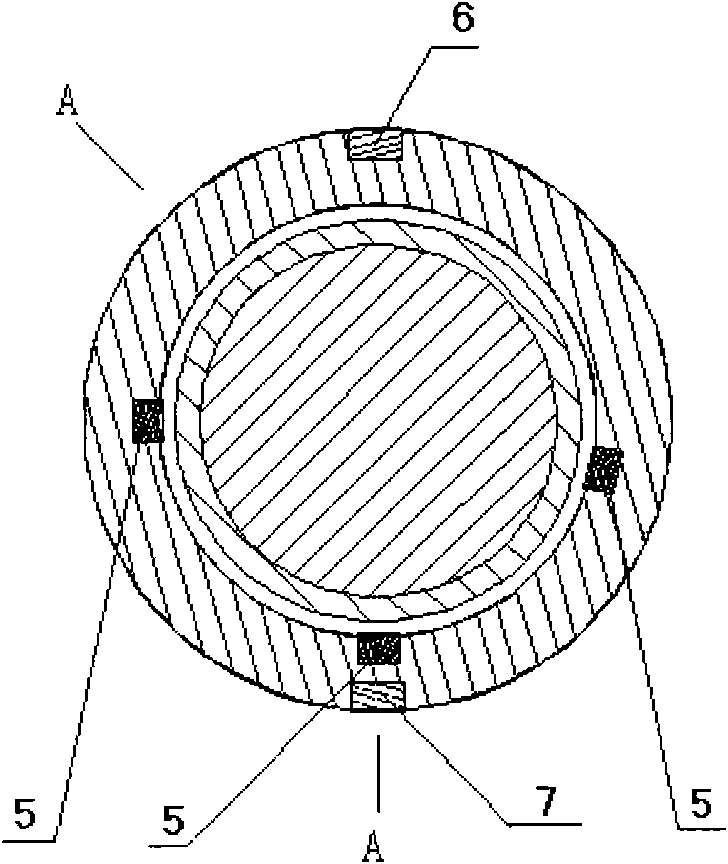

[0022] refer to figure 1 , figure 2 , the outer ring spacer 4 is radially arranged along the circumferential direction near the inner ring spacer 3, and three eddy current displacement sensors 5 are arranged to monitor the radial vibration displacement of the main shaft 1; the outer ring spacer 4 is axially arranged with an eddy current sensor 5 The displacement sensor 5 is used to test the axial vibration displacement of the inner ring spacer 3 as the axial movement of the main shaft; the outer ring spacer 4 is slotted near the outer ring of the left bearing in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com