Induction quenching method of shifting guide shaft of automatic transmission

A technology of induction hardening and gearbox, applied in the direction of furnace types, furnaces, heat treatment furnaces, etc., can solve the inevitable problems of hole wall melting, melting, over-burning, etc., to avoid over-burning and melting phenomena, and meet the performance requirements , the effect of simple structure and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

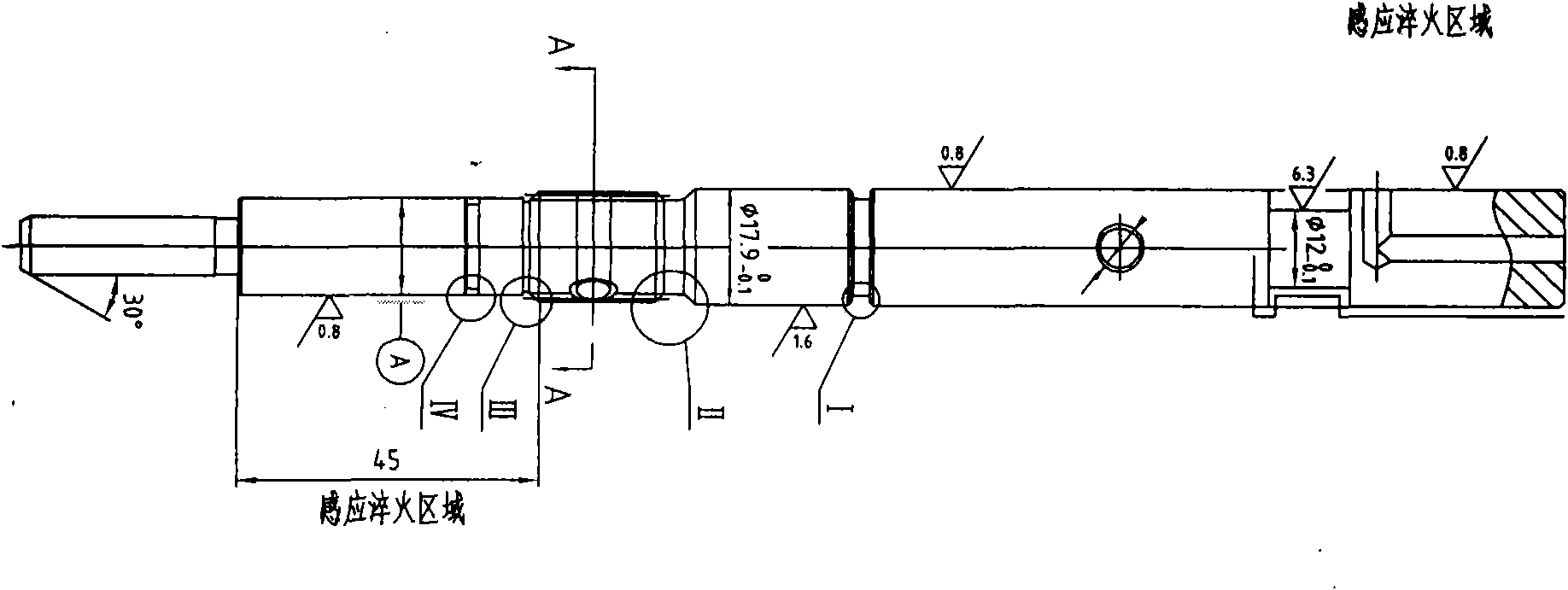

[0008] Embodiment 1: as figure 1 shown

[0009] Part name: shift guide shaft

[0010] Part number: 1707121-A9G

[0011] Induction hardening technical requirements:

[0012] Material: 45A08M-12.2

[0013] Induction hardening area: surface hardness 40 ~ 48HRC according to A08M-8.2

[0014] Effective hardened layer depth journal DS450HV51.0~3.0.

[0015] Test conditions

[0016] Use high frequency chamber MOSFET vertical high frequency induction hardening equipment, frequency: 30kHz; rated power: 100kW.

[0017] According to the standard (specification): LG-G06-R12-2008-0012 "Auto parts induction hardening process test specification"

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com