Method for doping magnetic particles of ferroferric oxide in titanium dioxide nanotube

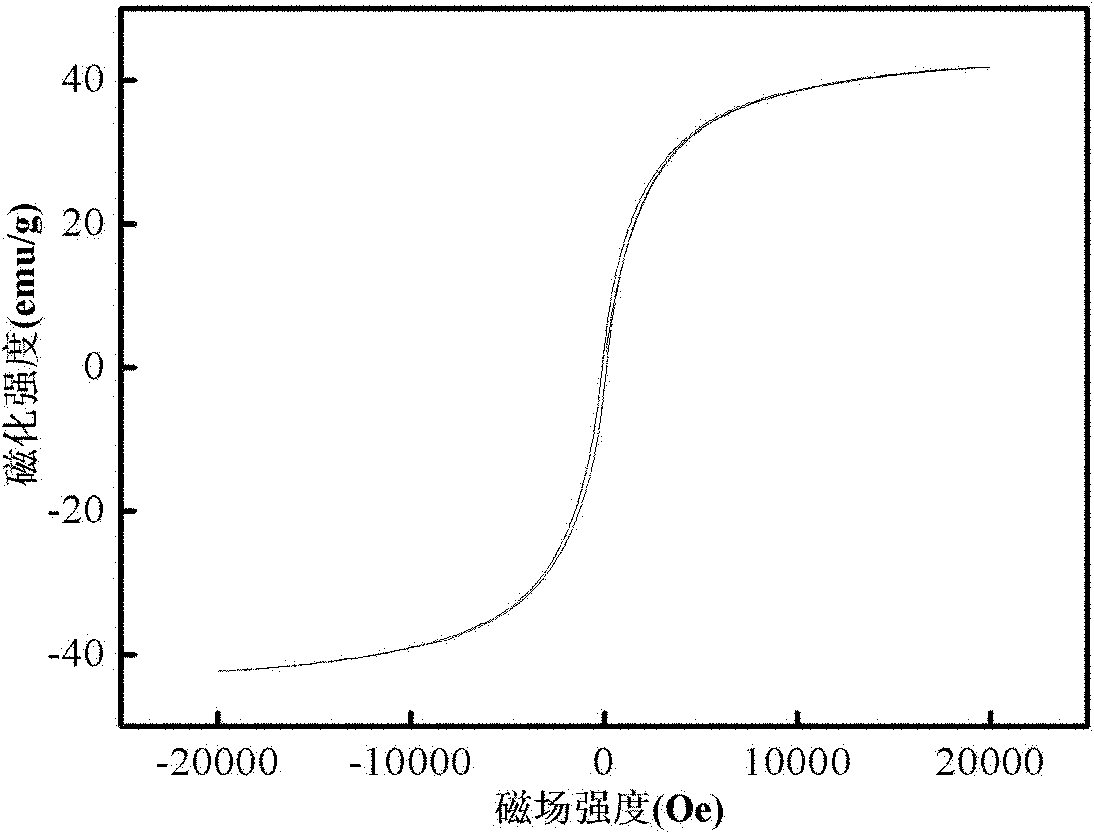

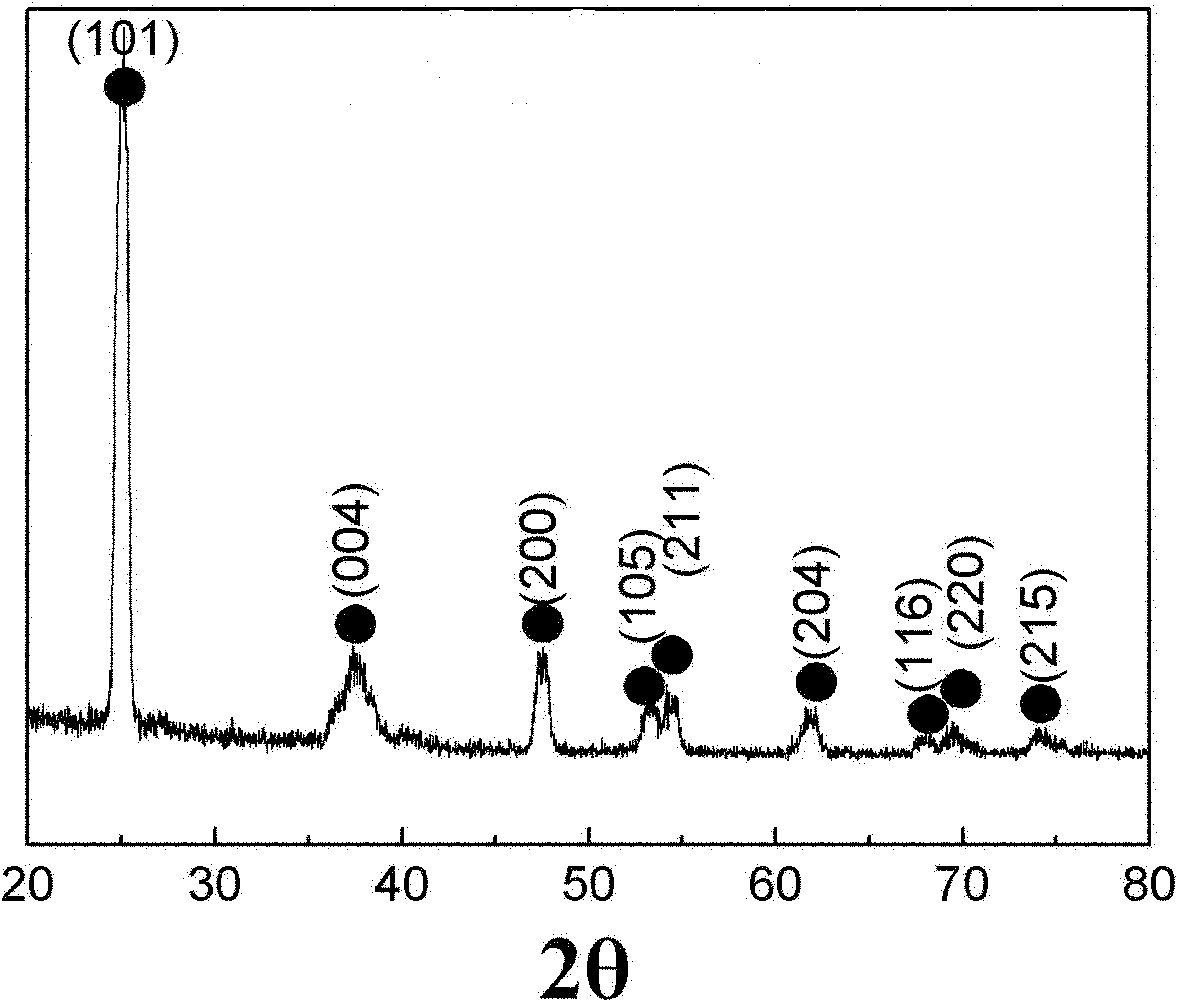

A technology of triiron tetroxide and titanium dioxide, used in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problems of toxic solvents, complex preparation processes, and high reaction temperatures, and achieve shortened reaction time and chemical properties. Stable, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) A two-electrode system (titanium sheet for the anode and platinum sheet for the cathode), electrolyte concentration: glycerol: water volume ratio 1:1, NH 4 The concentration of F is 0.27mol / L, the voltage is 35V, and the time is 3h, the self-assembled TiO 2 nanotube.

[0025] (2) A three-electrode system is adopted (the cathode is prepared with TiO 2 Titanium sheets of nanotubes, the anode is a platinum sheet, and the reference electrode uses a calomel electrode), the concentration of the electrolyte: the volume ratio of glycerol: water is 1:1, FeCl 3 The concentration is 0.02mol / L, the voltage is -3V, and the time is 15min, that is, in TiO 2 Nano ferromagnetic particles uniformly distributed on the surface of the nanotube.

Embodiment 2

[0027] (1) A two-electrode system is used (the anode is Ti-Zr-Nb alloy, wherein the atomic molar ratio of Ti, Zr and Nb is 73:2:25, and the cathode is platinum sheet), the electrolyte concentration: the volume ratio of glycerol: water 1:1, NH 4 The concentration of F is 0.27mol / L, the voltage is 35V, and the time is 3h, the self-assembled TiO 2 nanotube.

[0028] (2) A three-electrode system is adopted (the cathode is prepared with TiO 2 Titanium alloy sheets of nanotubes, the anode is a platinum sheet, and the reference electrode uses a calomel electrode), the concentration of the electrolyte: the volume ratio of glycerol: water is 1:1, FeCl 3 The concentration is 0.02mol / L, the voltage is -3V, and the time is 30min, that is, in TiO 2 Nano ferromagnetic particles uniformly distributed on the surface of the nanotube.

Embodiment 3

[0030] (1) A two-electrode system (titanium sheet for the anode and platinum sheet for the cathode), electrolyte concentration: glycerol: water volume ratio 1:1, NH 4 The concentration of F is 0.3mol / L, the voltage is 30V, and the time is 3h, the self-assembled TiO 2 nanotube.

[0031] (2) A three-electrode system is adopted (the cathode is prepared with TiO 2 Titanium sheets of nanotubes, the anode is a platinum sheet, and the reference electrode uses a calomel electrode), the concentration of the electrolyte: the volume ratio of glycerol: water is 1:1, FeCl 3 The concentration is 0.02mol / L, the voltage is -3V, and the time is 45min, that is, in TiO 2 Nano ferromagnetic particles are evenly distributed on the surface of the nanotube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com