Method for doping nano-Ag particles in TiO2 nanotubes

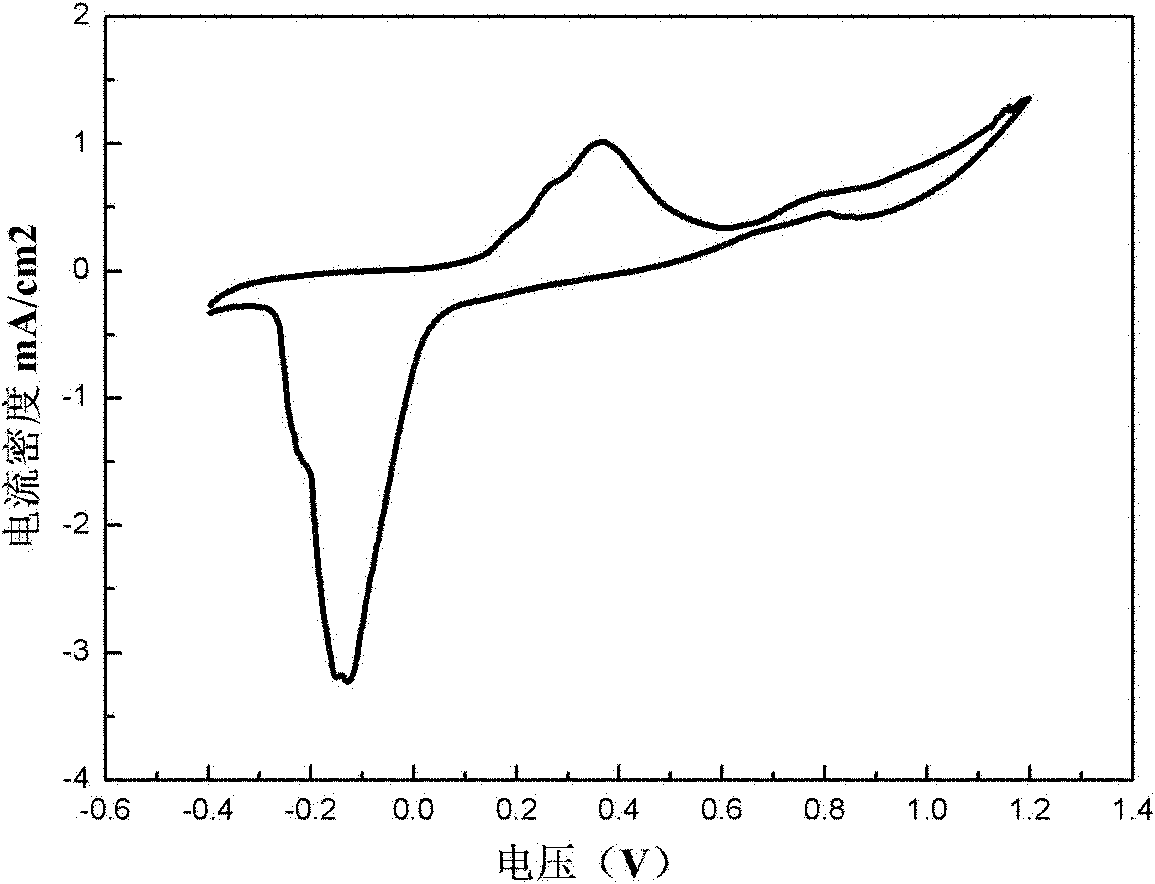

A technology of nano-silver particles and titanium dioxide, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve the difficulty of nano-particles on the surface of nano-tubes and uneven distribution of nanoparticles , complex preparation process, etc., to achieve the effects of shortened reaction time, simple operation, and high electrocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

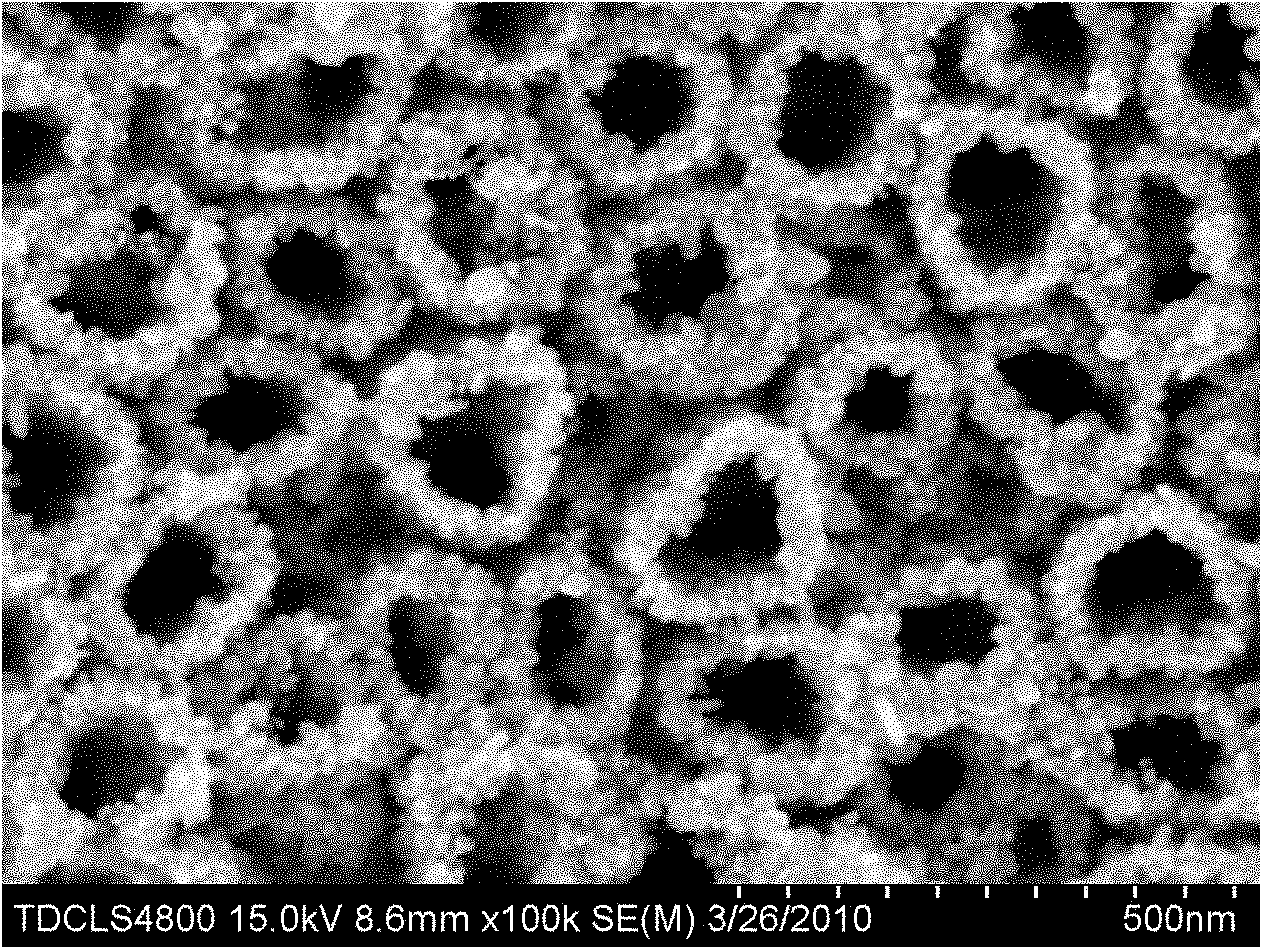

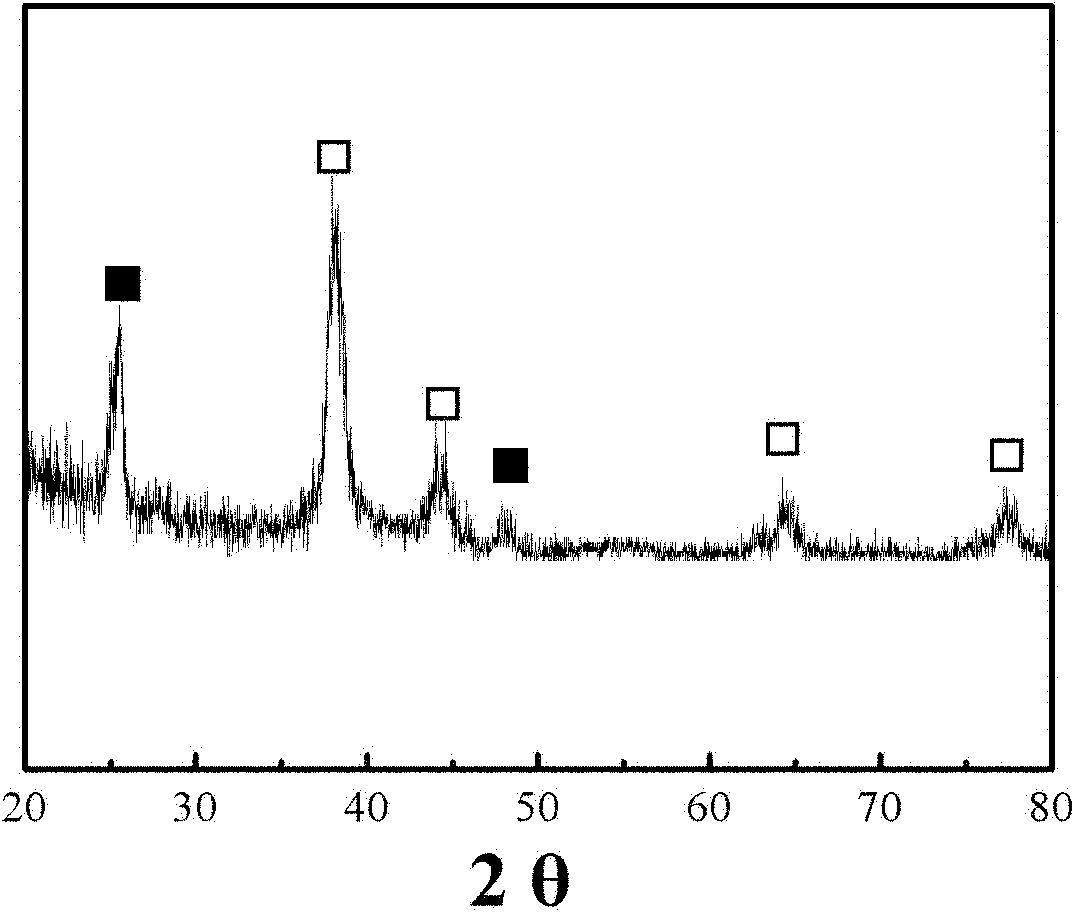

[0021] (1) A two-electrode system (titanium sheet for the anode and platinum sheet for the cathode), electrolyte concentration: glycerol: water volume ratio 1:1, NH 4 The concentration of F is 0.3mol / L, the voltage is 30V, and the time is 3h, the self-assembled TiO 2 nanotube.

[0022] (2) TiO prepared by step (1) 2 The titanium sheet of the nanotube is placed in a silver nitrate solution and deposited at 40° C. for 7 hours. In the silver nitrate solution, the volumes of ethylene glycol and water are each 25 ml, the concentration of polyvinylpyrrolidone is 0.001 mol / L, and NaBH 4 The concentration is 0.048mol / L, AgNO 3 The concentration is 0.045mol / L.

Embodiment 2

[0024] (1) A two-electrode system is used (the anode is Ti-Zr-Nb alloy, wherein the atomic molar ratio of Ti, Zr and Nb is 73:2:25, and the cathode is platinum sheet), the electrolyte concentration: the volume ratio of glycerol: water 1:1, NH 4 The concentration of F is 0.3mol / L, the voltage is 30V, and the time is 3h, the self-assembled TiO 2 nanotube.

[0025] (2) TiO prepared by step (1) 2 The Ti-Zr-Nb alloy of the nanotube is placed in a silver nitrate solution and deposited at 40° C. for 3 hours. In the silver nitrate solution, the volumes of ethylene glycol and water are each 25 ml, and the concentration of polyvinylpyrrolidone is 0.001 mol / L. NaBH 4 The concentration is 0.048mol / L, AgNO 3 The concentration is 0.045mol / L.

Embodiment 3

[0027] (1) A two-electrode system (titanium sheet for the anode and platinum sheet for the cathode), electrolyte concentration: glycerol: water volume ratio 1:1, NH 4 The concentration of F is 0.3mol / L, the voltage is 30V, and the time is 3h, the self-assembled TiO 2 nanotube.

[0028] (2) TiO prepared by step (1) 2 The titanium sheet of the nanotube is placed in a silver nitrate solution and deposited at 50° C. for 7 h. In the silver nitrate solution, the volumes of ethylene glycol and water are each 25 ml, the concentration of polyvinylpyrrolidone is 0.001 mol / L, and NaBH 4 The concentration is 0.048mol / L, AgNO 3 The concentration is 0.045mol / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com