High-performance micro electromagnetic vibration energy harvester easy for integrated manufacturing

An electromagnetic vibration and energy harvester technology, applied in electrical components, electromechanical devices, etc., can solve the problems of weak magnetic field, difficult to integrate manufacturing, large size of devices, etc., and achieve the effect of high thickness and magnetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

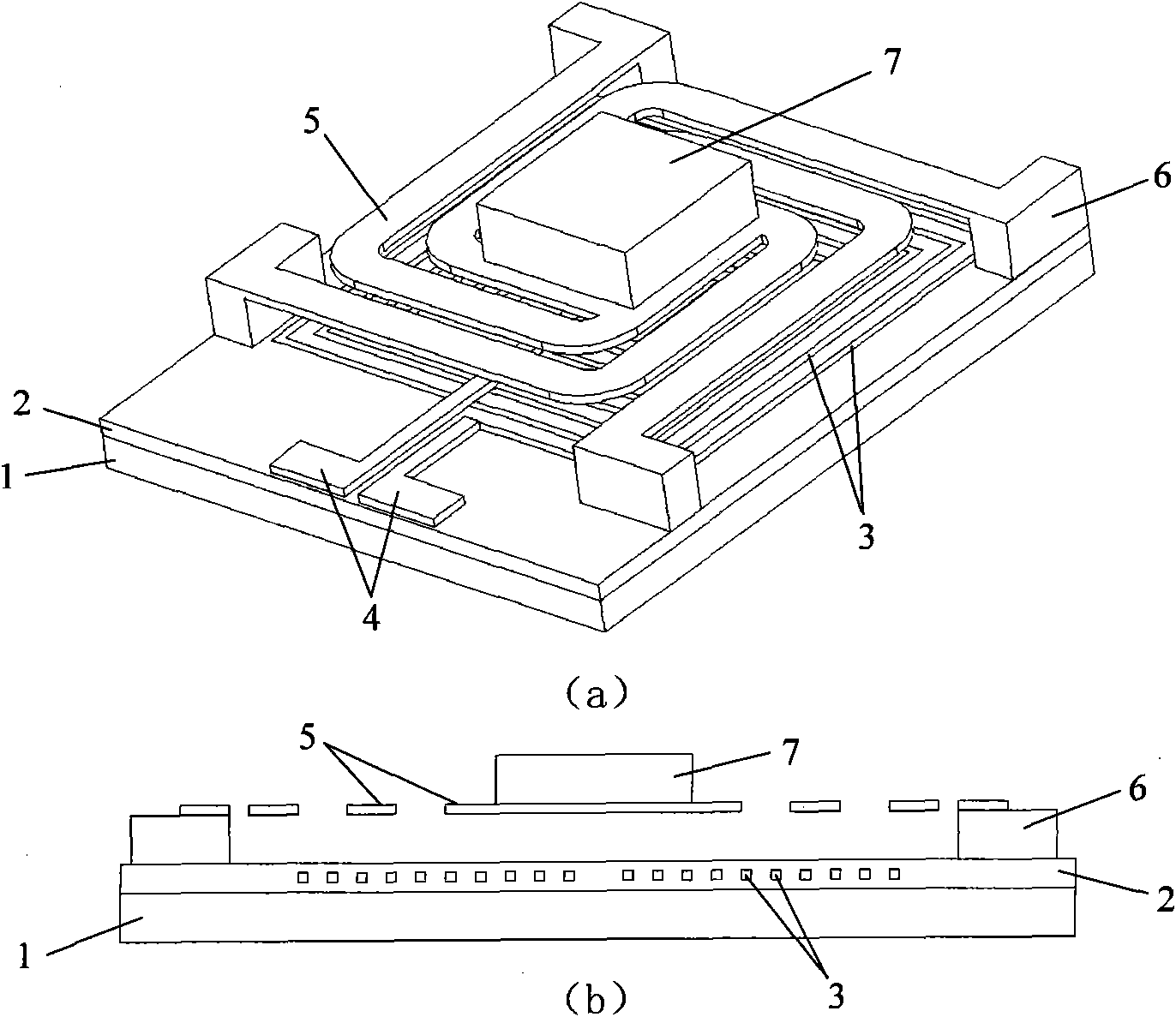

[0029] Embodiment 1: A high-performance miniature electromagnetic vibration energy harvester that is easy to integrate and manufacture

[0030] see figure 1 (a), the high-performance miniature electromagnetic vibration energy harvester that the present embodiment is easy to integrated manufacturing comprises: substrate 1, insulating layer 2, coil 3, electrode 4, spring platform 5, supporting seat 6 and permanent magnet 7; 2 is directly connected to the substrate 1 and is located on the substrate 1. The coil 3 is also directly connected to the substrate 1 and is located on the substrate 1 and is wrapped by an insulating layer 2. The thickness of the insulating layer 2 is basically the same as that of the coil 3. 2 to 20 microns, the two ends of the electrode 4 are respectively connected to the two ends of the coil 3, used to lead out the electromotive force induced in the coil 3 to the external circuit, the electrode 4 is connected to the insulating layer 2, and is located on t...

Embodiment 2

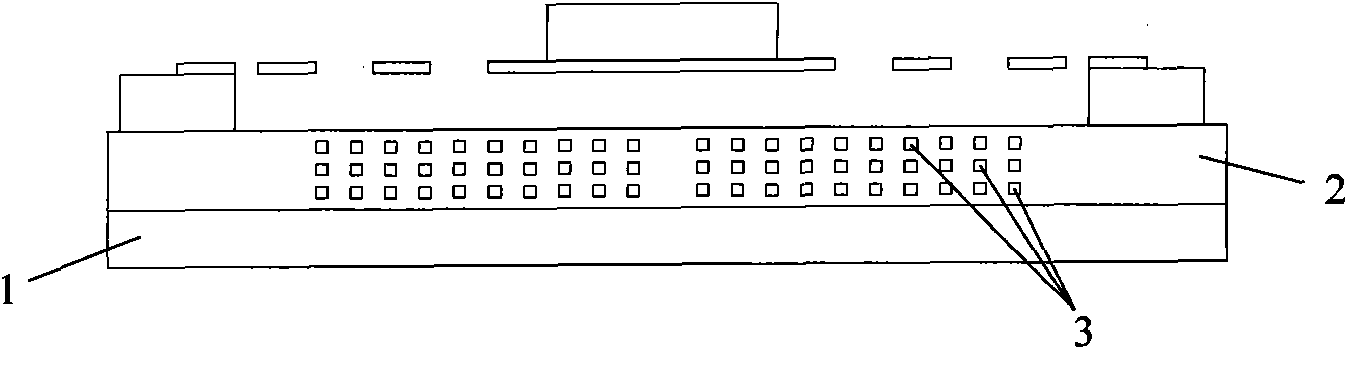

[0033] Embodiment 2: A high-performance miniature electromagnetic vibration energy harvester that is easy to integrate and manufacture with three layers of coils.

[0034] see figure 2 , the miniature electromagnetic vibration energy harvester adopts a laminated structure of three-layer coil 3, and the three-layer structure does not interfere with each other, and is superimposed in the vertical direction, all wrapped in the insulating layer 2, the energy harvester The size of the energy harvester with a coil structure in Embodiment 1 is consistent with that of Embodiment 1, and except for the number of coil layers, the shape and size of other components are consistent with Embodiment 1.

Embodiment 3

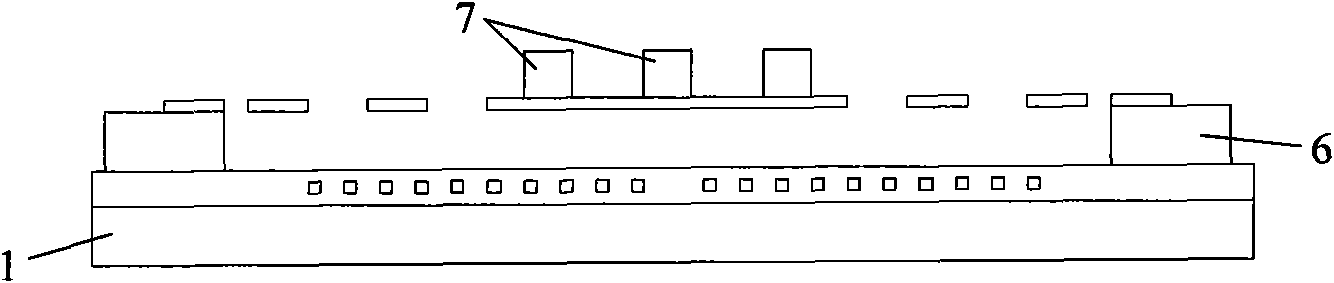

[0035] Embodiment 3: A high-performance miniature electromagnetic vibration energy harvester that is easy to integrate and manufacture with an array of permanent magnets.

[0036] see image 3 , the permanent magnet 7 of the miniature electromagnetic vibration energy harvester is formed by an array of smaller structures, the array structure is in the form of 3×3, and the area of each part is (10~120)×(120~300) square microns , the thickness is 10-800 microns, the row spacing is 10-30 microns, and the column spacing is 10-30 microns. The other features of the micro vibration energy harvester are similar to those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com