Industrial control network experimental platform based on filed buses and control method thereof

A technology of industrial control network and field bus, which is applied in the field of bus network, comprehensive factory control, comprehensive factory control, etc., and can solve the problems that students cannot master the characteristics of various field buses and the interconnection of different field buses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

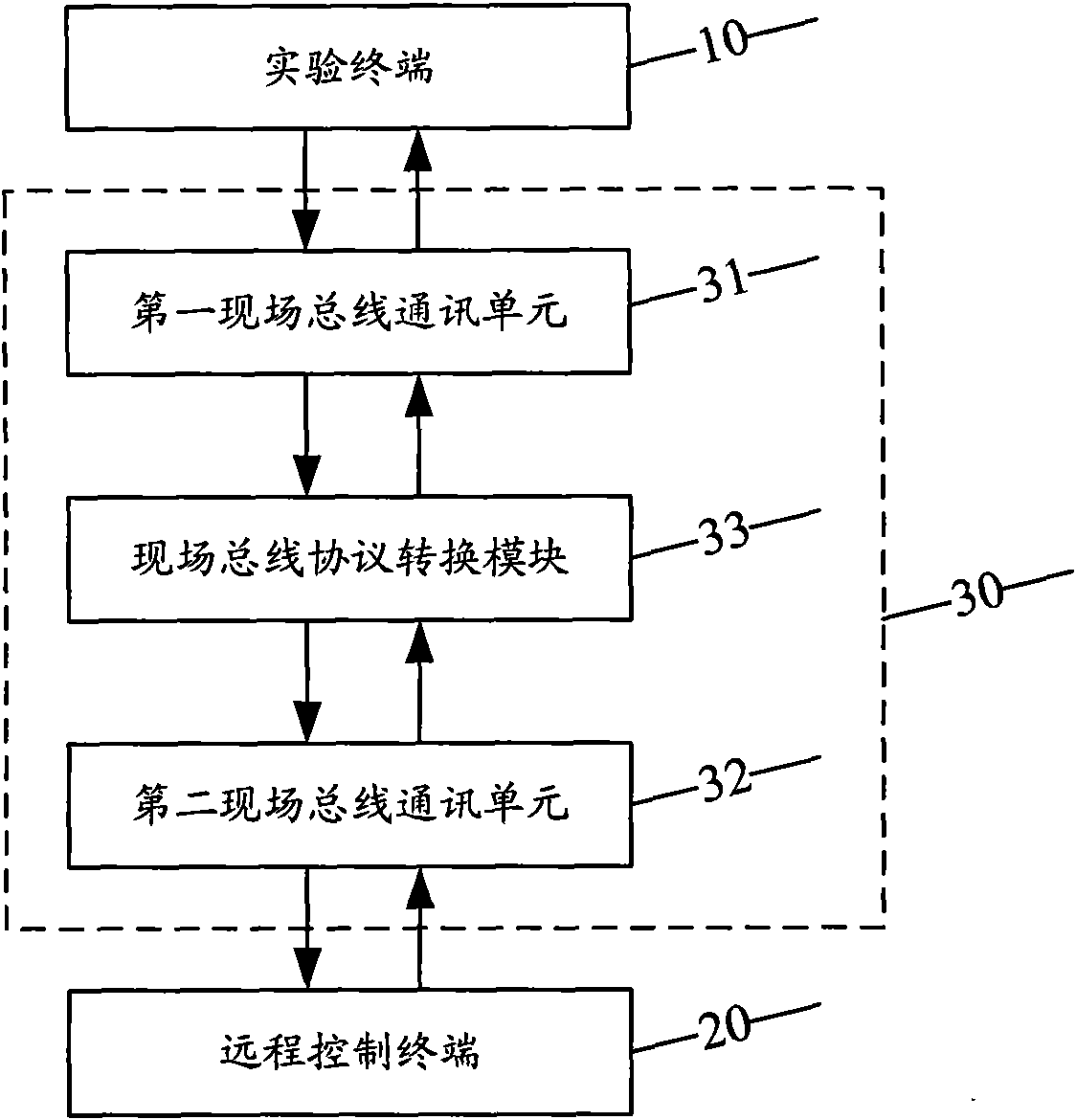

[0034] see figure 1 , the present invention discloses a fieldbus-based industrial control network experiment platform, which includes an experiment terminal 10, a communication module 30, and a remote control terminal 20 connected in sequence.

[0035] The experimental terminal 10 includes a programmable controller and a computer equipped with corresponding development software, through which the engineering project of the terminal can be established. The programmable controller in this embodiment is a programmable computer controller PCC, and the controller PCC controls the field bus to transmit variable information. The remote control terminal 20 is used to remotely control the experiment terminal; the remote control terminal 20 includes a programmable controller PLC and a computer equipped with corresponding PLC programming software. The communication module 30 is used for transmitting data between the experiment terminal and the remote control terminal.

[0036] Such as ...

Embodiment 2

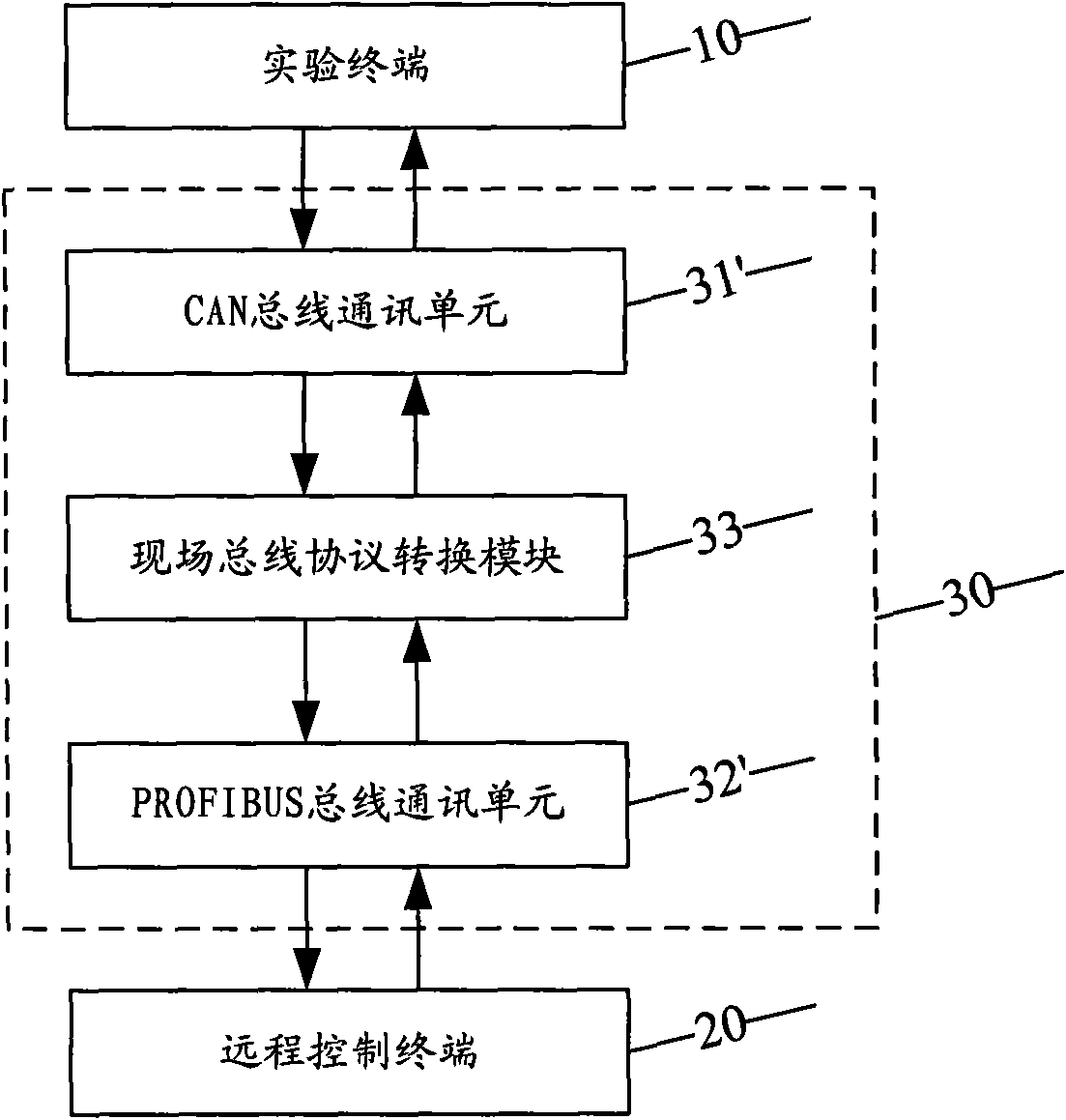

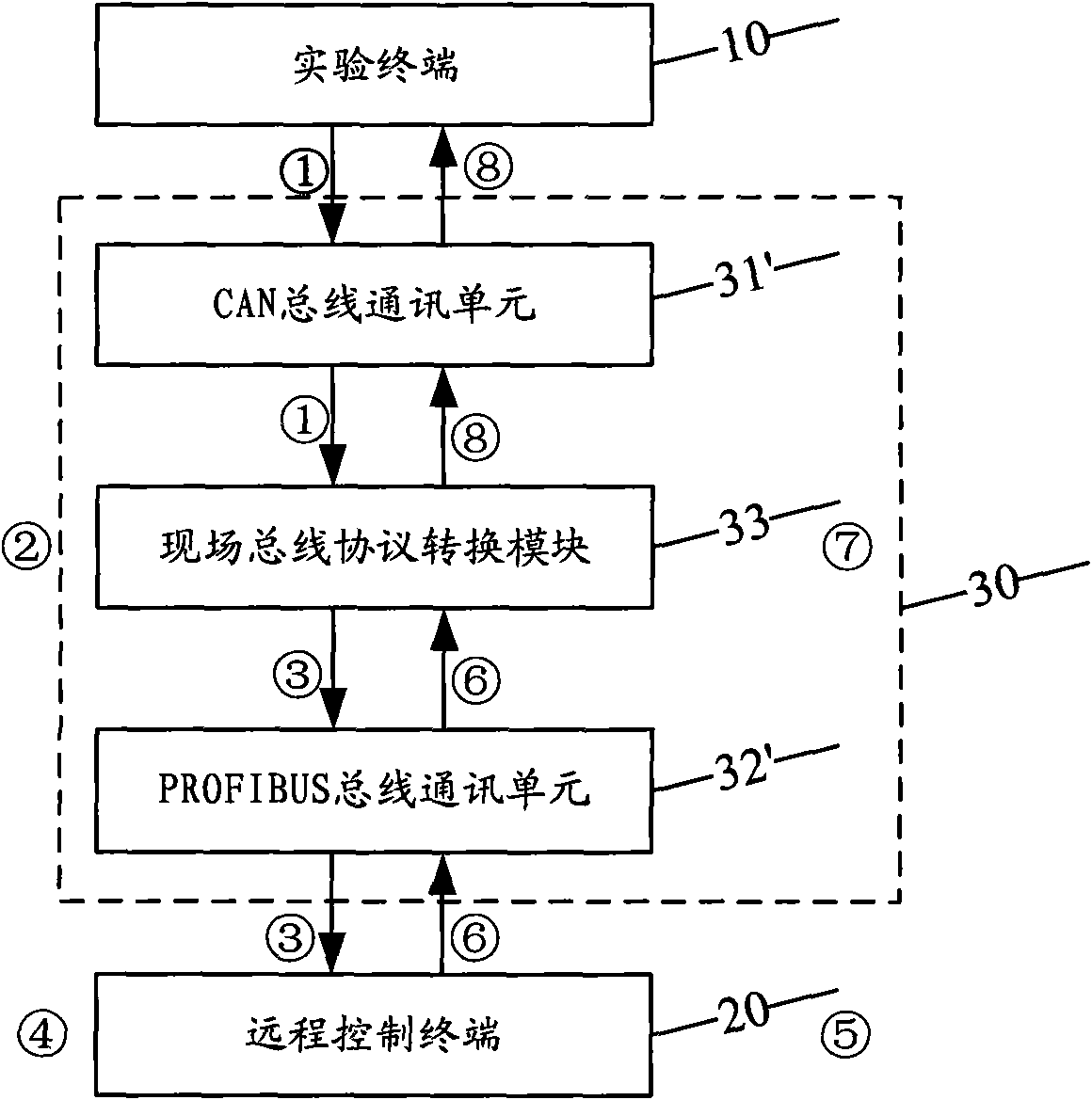

[0050] The difference between this embodiment and Embodiment 1 is that in this embodiment, the communication module 30 includes at least two groups of field bus communication unit groups 310, 320; the first field bus communication unit group 310 is arranged between the experimental terminal and the field Between the bus protocol conversion modules, the second field bus communication unit group 320 is arranged between the remote control terminal and the field bus protocol conversion module.

[0051] Each fieldbus communication unit group 310, 320 includes one or more, one or more types of fieldbus communication units. The two fieldbus communication unit groups are connected through the fieldbus protocol conversion module group 330, and the fieldbus protocol conversion module group 330 includes one or any number of fieldbus protocol conversion modules.

[0052] see Figure 4A , Figure 4A Among them, the first field bus communication unit group 310 includes several one type or...

Embodiment 3

[0058] The difference between this embodiment and the above embodiments is that in this embodiment, the communication module includes several parallel communication sub-modules; each communication sub-module includes at least two types of The field bus communication unit is used to transmit the data between the experiment terminal and the remote control terminal; a field bus protocol conversion module is set between the different field bus communication units connected in series.

[0059] Such as Figure 5 As shown, in this embodiment, the communication module 30 includes three parallel communication sub-modules 300, and each communication sub-module 300 includes two different types of field bus communication units 31, 32, and the two serial connection field bus communication units A field bus protocol conversion module 33 is set between 31 and 32 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com