Externally buried tubular column surrounding type intercepting filter rod

A technology of nozzle rod and pipe column, which is applied in the field of filter fiber nozzle rod, can solve the problem of low interception efficiency, achieve the effects of reducing bad smell, enhancing capacity and improving deposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

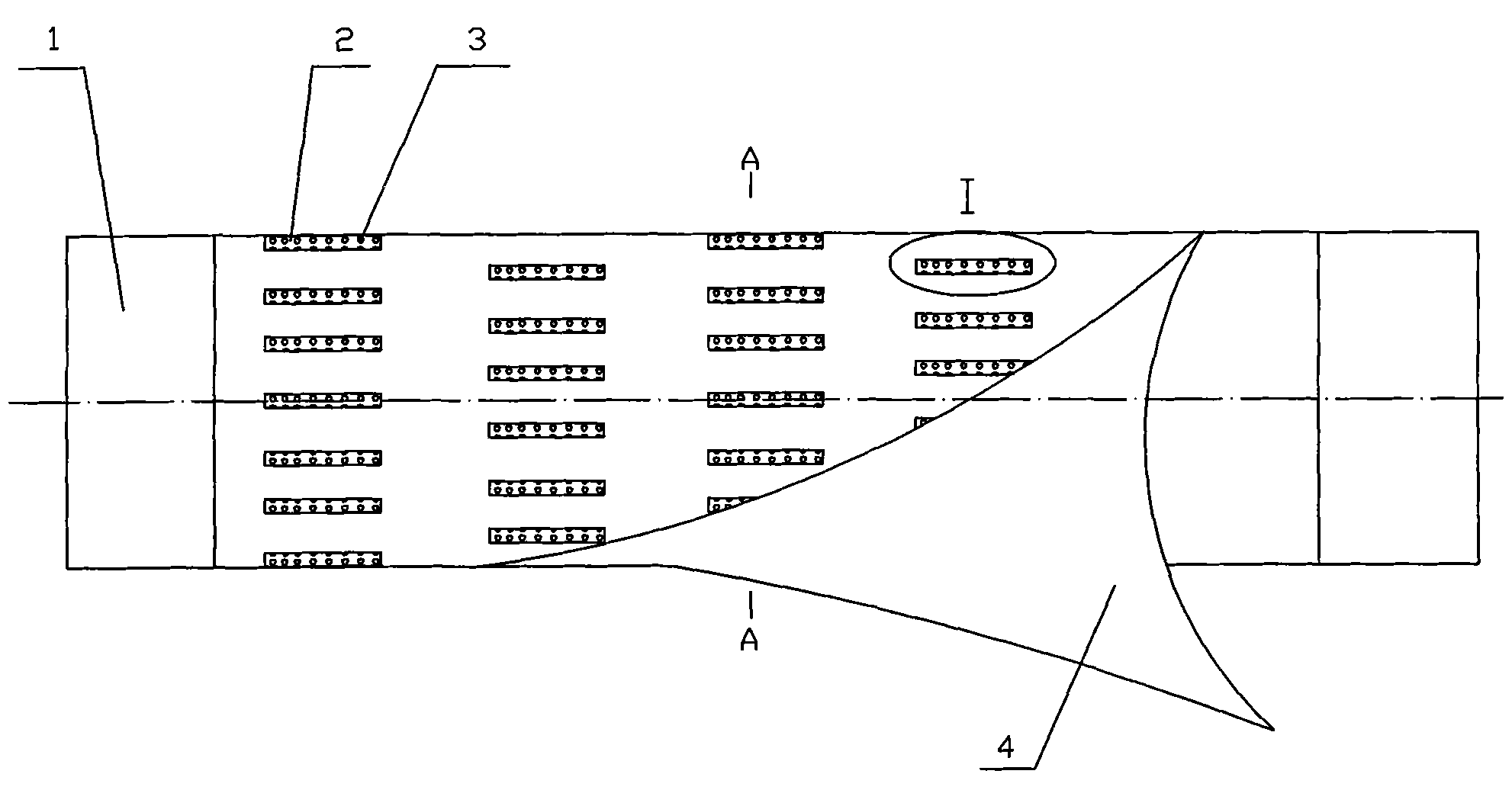

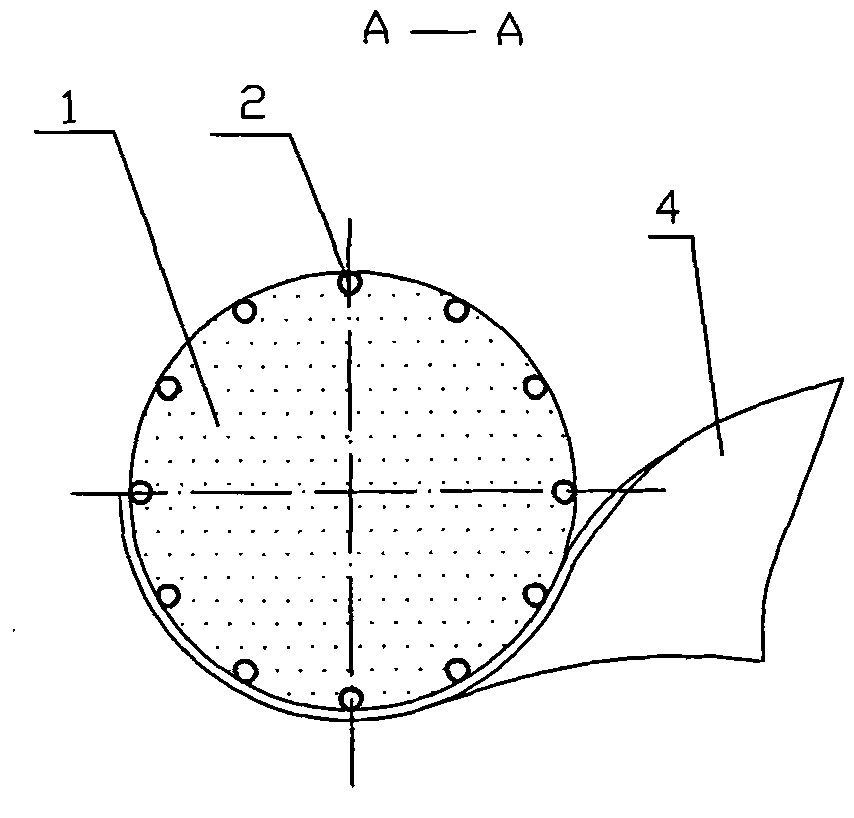

[0025] Such as figure 1 , figure 2 As shown, the present invention provides an externally-buried surrounding tube column trapping nozzle rod, which is composed of a tow core rod 1 and an outer layer of forming paper 4, and four tubes are arranged on the circumference of the tow core rod The core group is wrapped by the forming paper 4 on the tow core rod, and each tube core group is composed of 12 longitudinal tube cores 2 arranged along the circumference of the tow core rod.

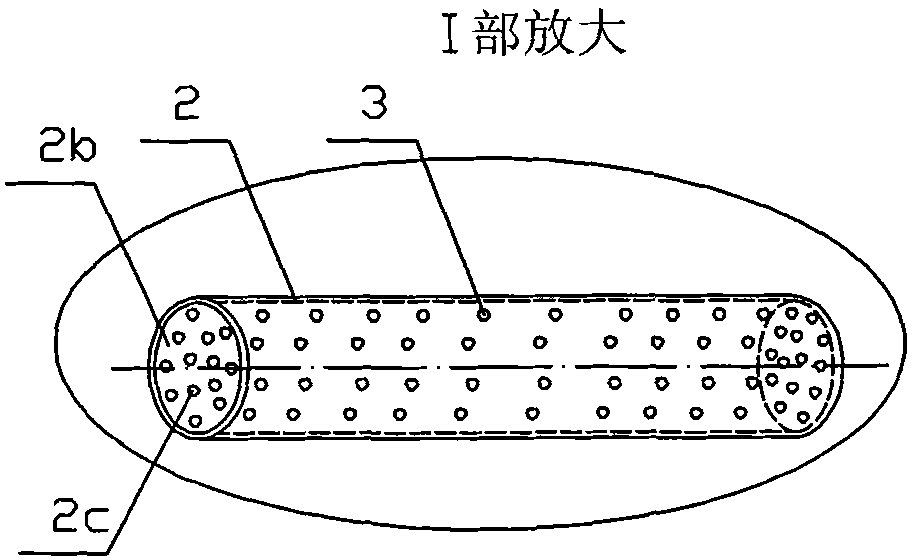

[0026] Such as image 3 As shown, the surface of each longitudinal tube core 2 is provided with a set of drainage small holes 3, both ends of the longitudinal tube core 2 are respectively provided with end caps 2b, and a set of small holes 2c are also provided on the end cap 2b. The small aperture is 0.01-1.0MM.

[0027] The longitudinal tube core compresses the tow core rod toward the center to increase the center density, forcing part of the flue gas to flow through the small hole into the longitudinal tu...

Embodiment 2

[0029] image 3 The vertical tube core 2 in the middle can be a solid cylinder 2a made of activated carbon or nanomaterials with high air permeability and high adsorption. The cylinder has micropores 3a that can adsorb flue gas, such as activated carbon, sepiolite, Sponge, etc., can also achieve the purpose of intercepting smoke.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com