Liquid air engine

A power machine, air-liquid technology, applied in the direction of variable volume engine, machine/engine, reciprocating piston engine, etc., can solve the problems of unachieved, unsatisfactory results, low energy efficiency utilization of liquid nitrogen, etc., to improve work efficiency, The effect of low power loss and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

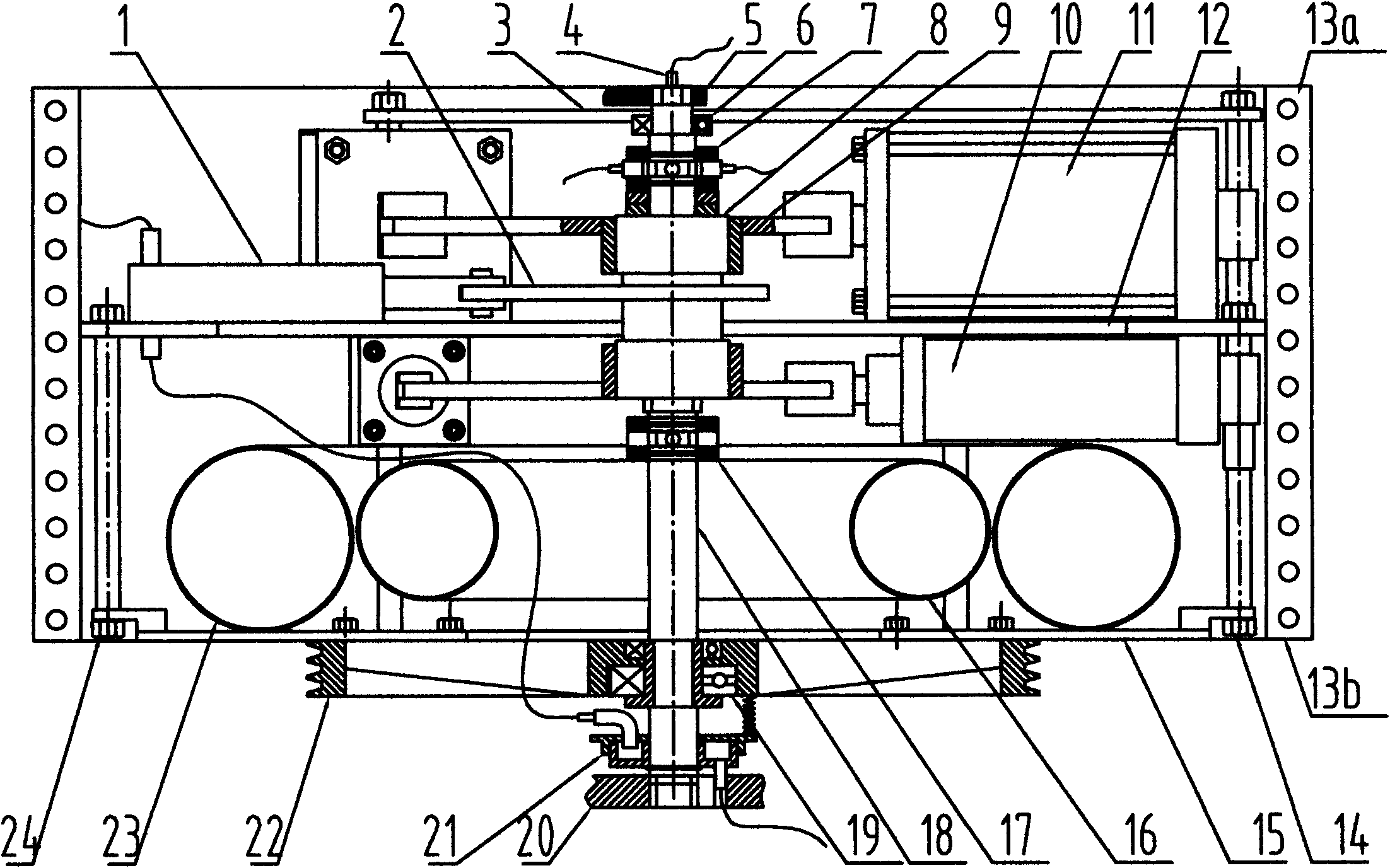

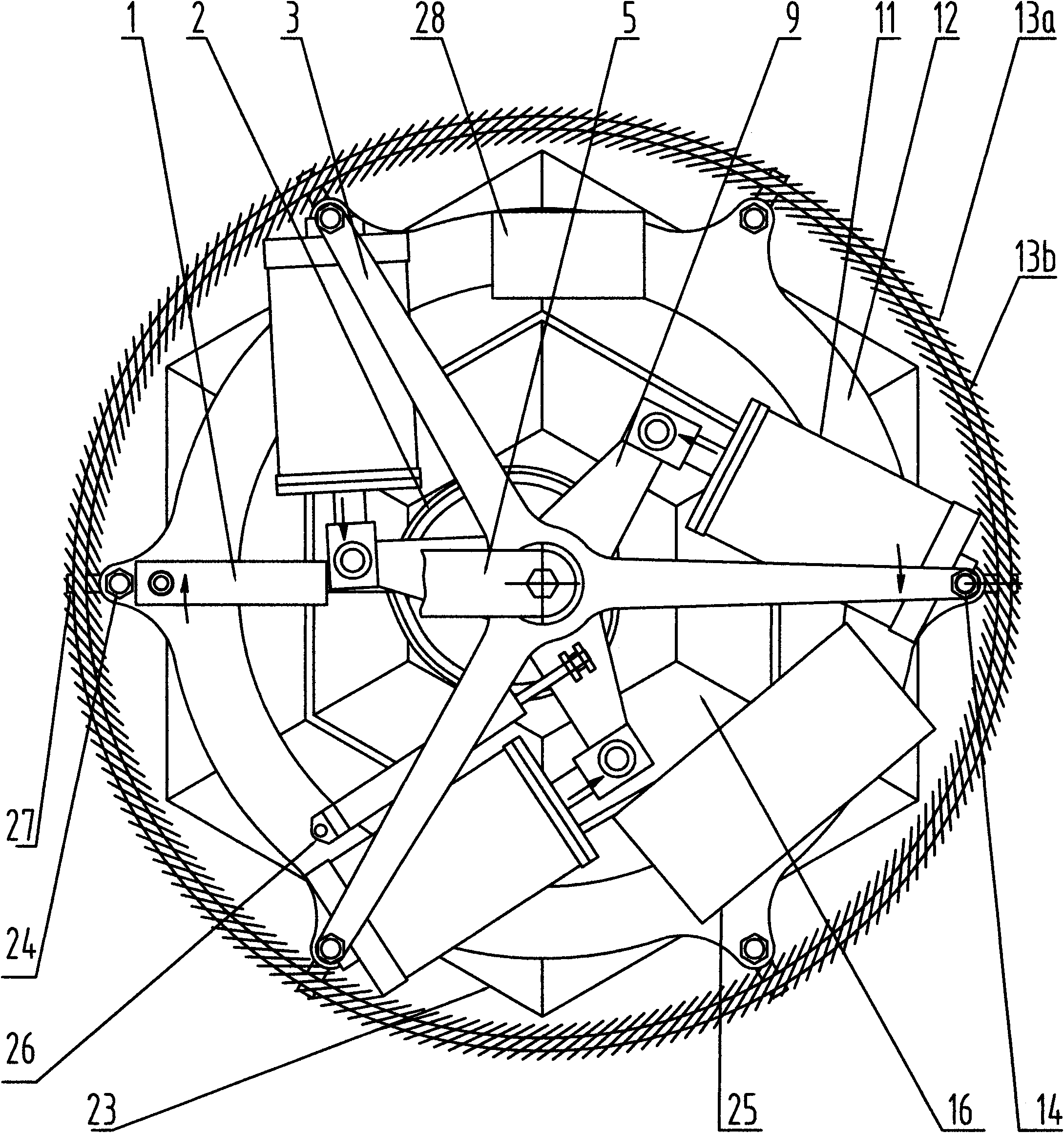

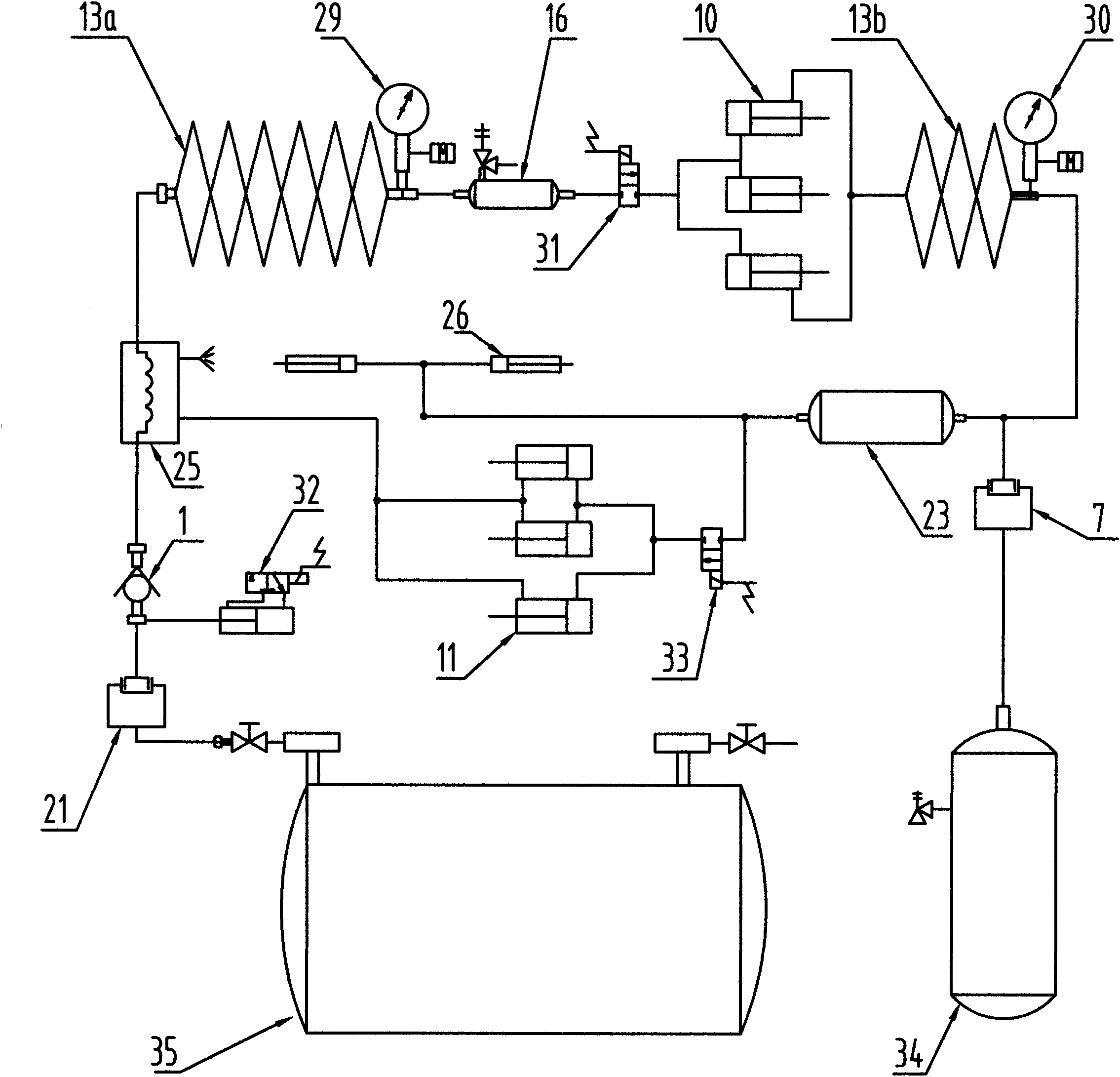

[0021] In accompanying drawing 1: upper bearing (5), lower bearing (20) are the fixed bearings of liquid-pneumatic power machine, fix central shaft (18) from upper end and lower end, and central shaft (18) is fixed and cannot rotate during work of. The upper bracket (3) is installed on the middle shaft (18) through the upper bracket bearing (6), the lower bracket (15) is fixed on the main transmission wheel (22), and the main transmission wheel (22) passes through the main transmission wheel bearing (19) Installed on the central axis, the bracket fixes the short screw rod (24) and the bracket fixes the long screw rod (14) to connect the lower bracket (15), the middle support plate (12), and the upper bracket (3) into a rotatable integral bracket. Cam (2), external air source joint (4), gas joint (7), one-way overrunning clutch (8), movable electric contact (17), liquid gas joint (21) are fixedly installed on the central shaft (18). ). Rocking bar (9) is connected with one-wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com