Large-power forward LED chip structure

A LED chip and high-power technology, applied in lighting devices, lighting device components, lighting device cooling/heating devices, etc. problem, to achieve the effect of improving light extraction efficiency, improving heat dissipation capacity, and realizing high power and high brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

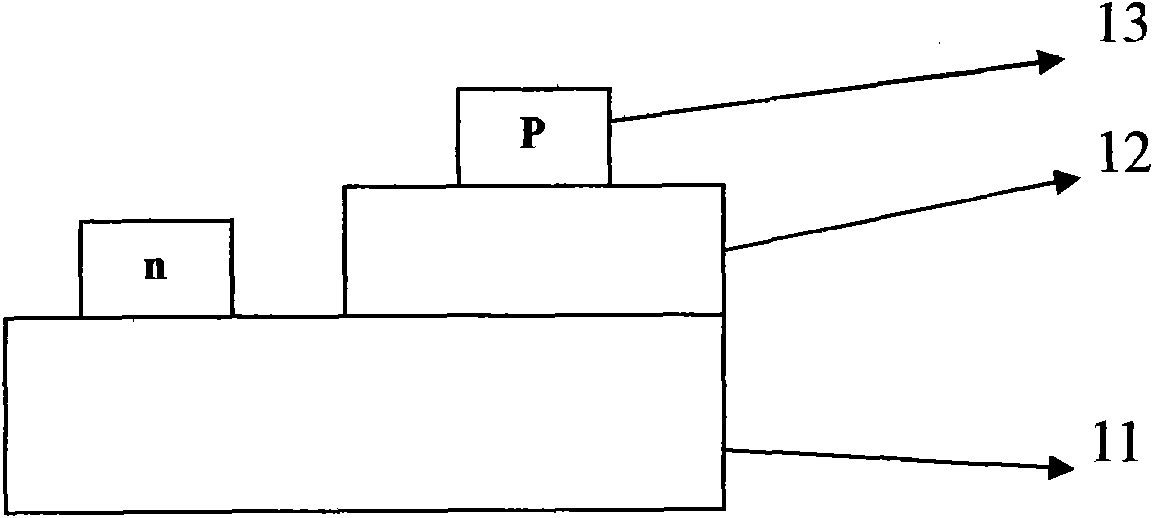

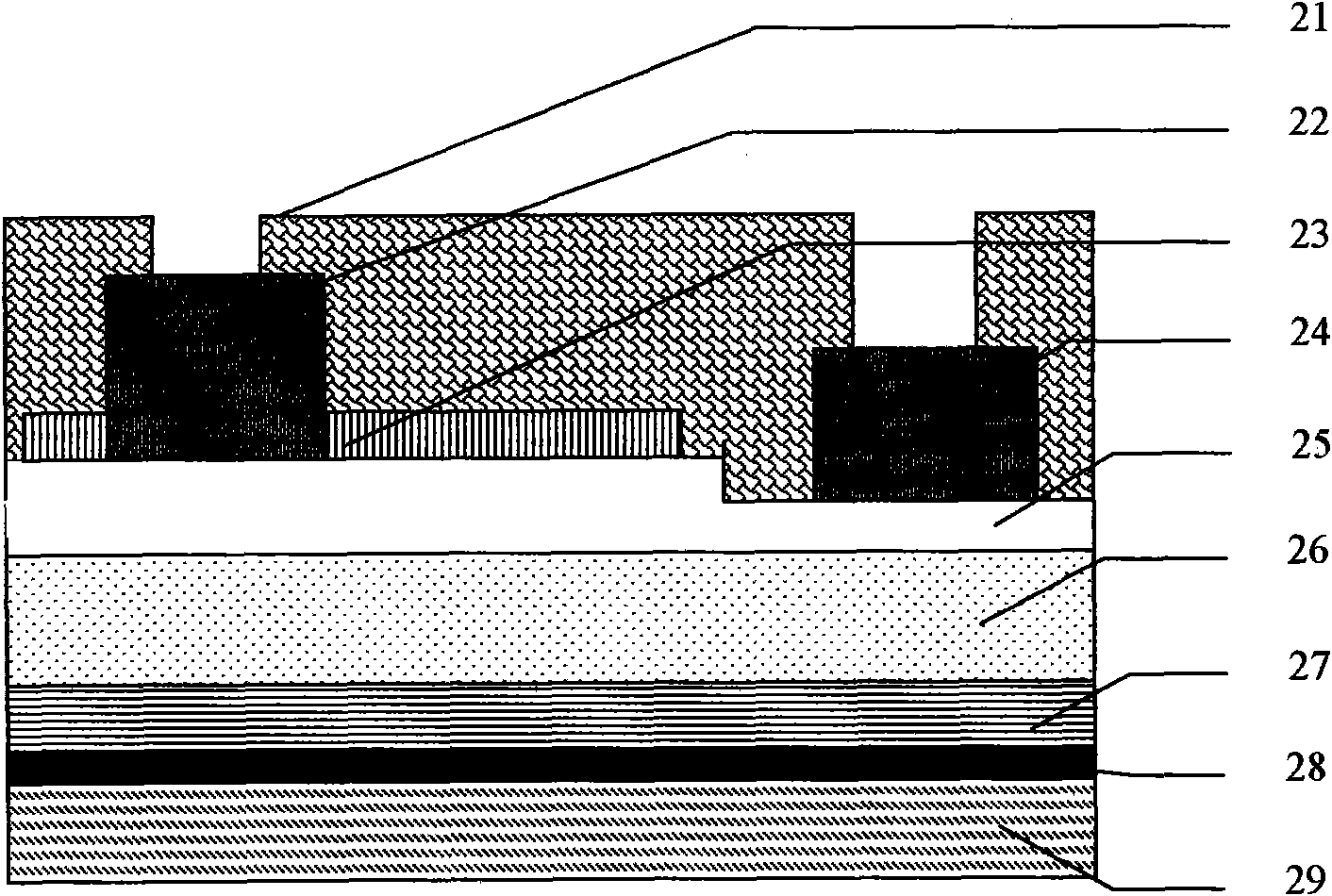

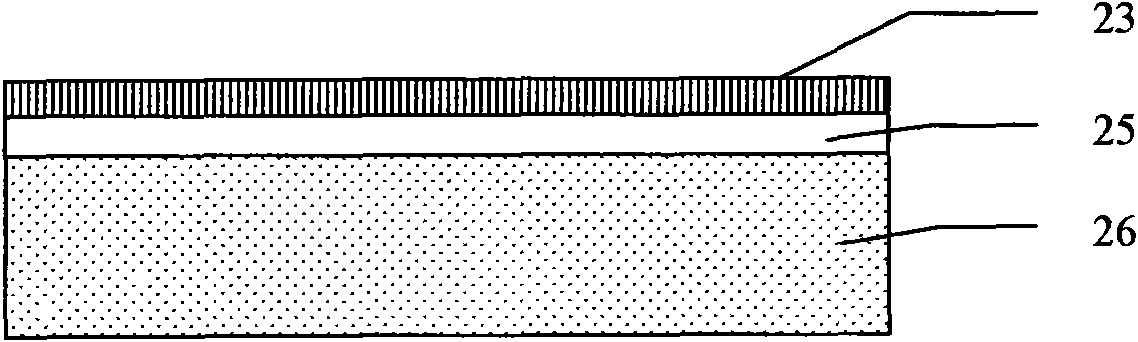

[0013] like figure 2 As shown, the present invention provides a high-power front-loading LED chip structure, including a transparent passivation layer 21, a P pressure pad 22, a transparent electrode layer 23, an N electrode 24, an LED epitaxial layer 25, a sapphire substrate 26, reflection and solder Layer 28, wherein: the surface of the reflective and solder layer 28 is formed with a DBR optical reflective layer 27 by means of optical coating, and a high thermal conductivity base layer 29 is provided at the bottom of the reflective and solder layer 28 .

[0014...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com