Key light guide assembly and key backlight module thereof

A technology of light guide components and backlight modules, applied in optical components, optics, light guides, etc., can solve the problems of expensive, complex phosphor manufacturing process, inconsistent with market trends, etc., achieve rapid mass production, improve light use efficiency, and reduce power consumption volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

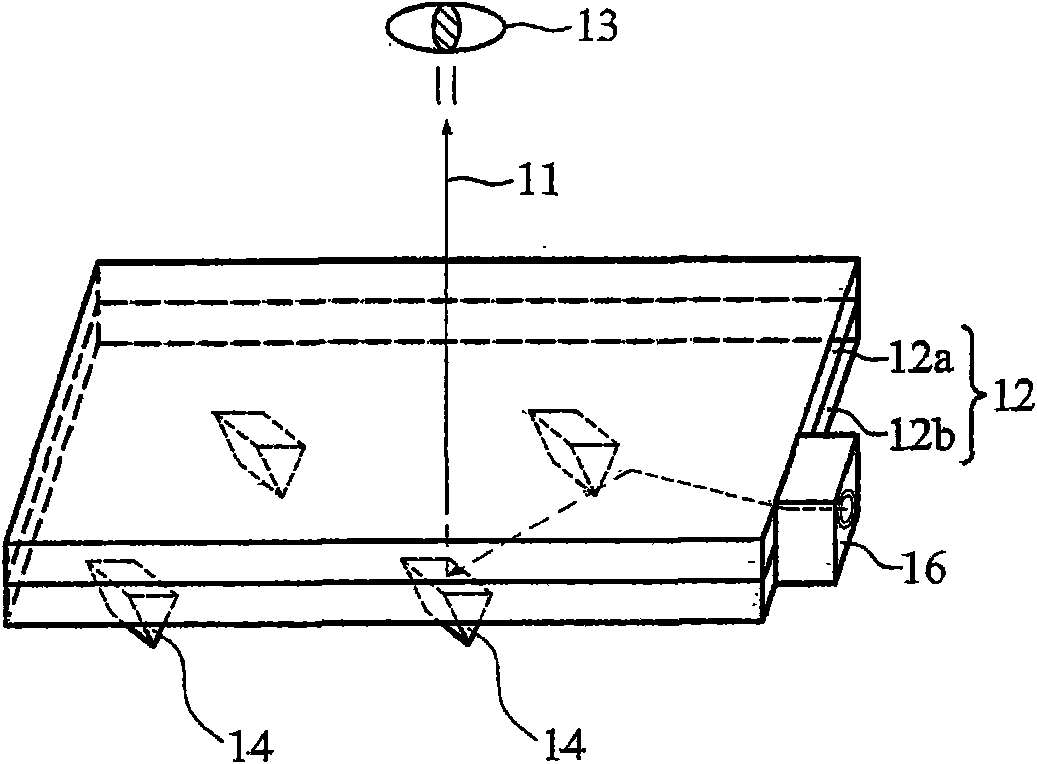

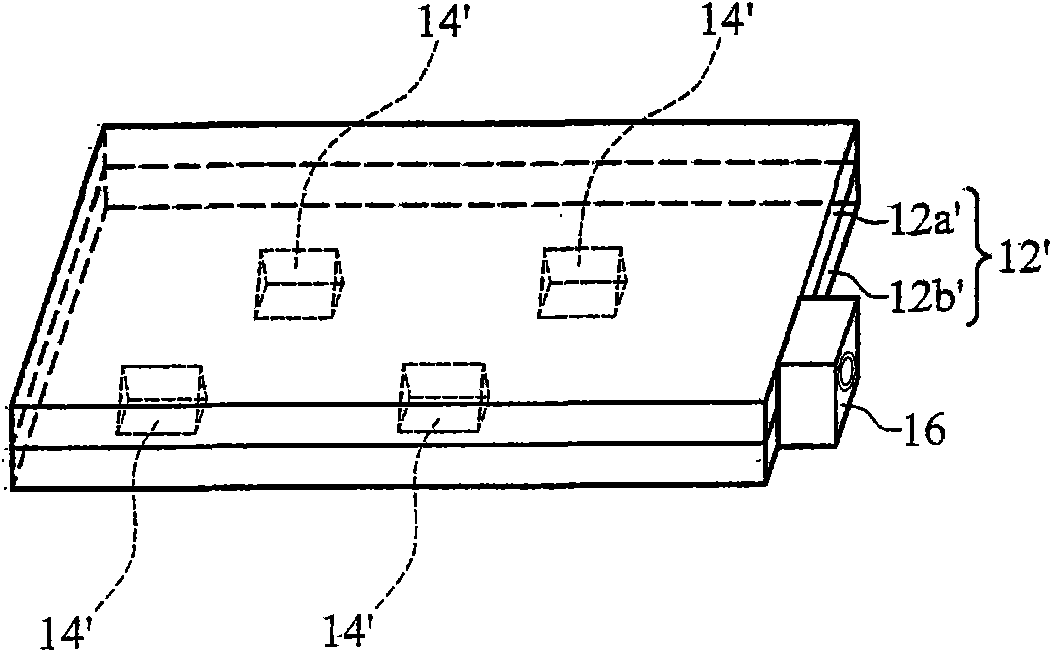

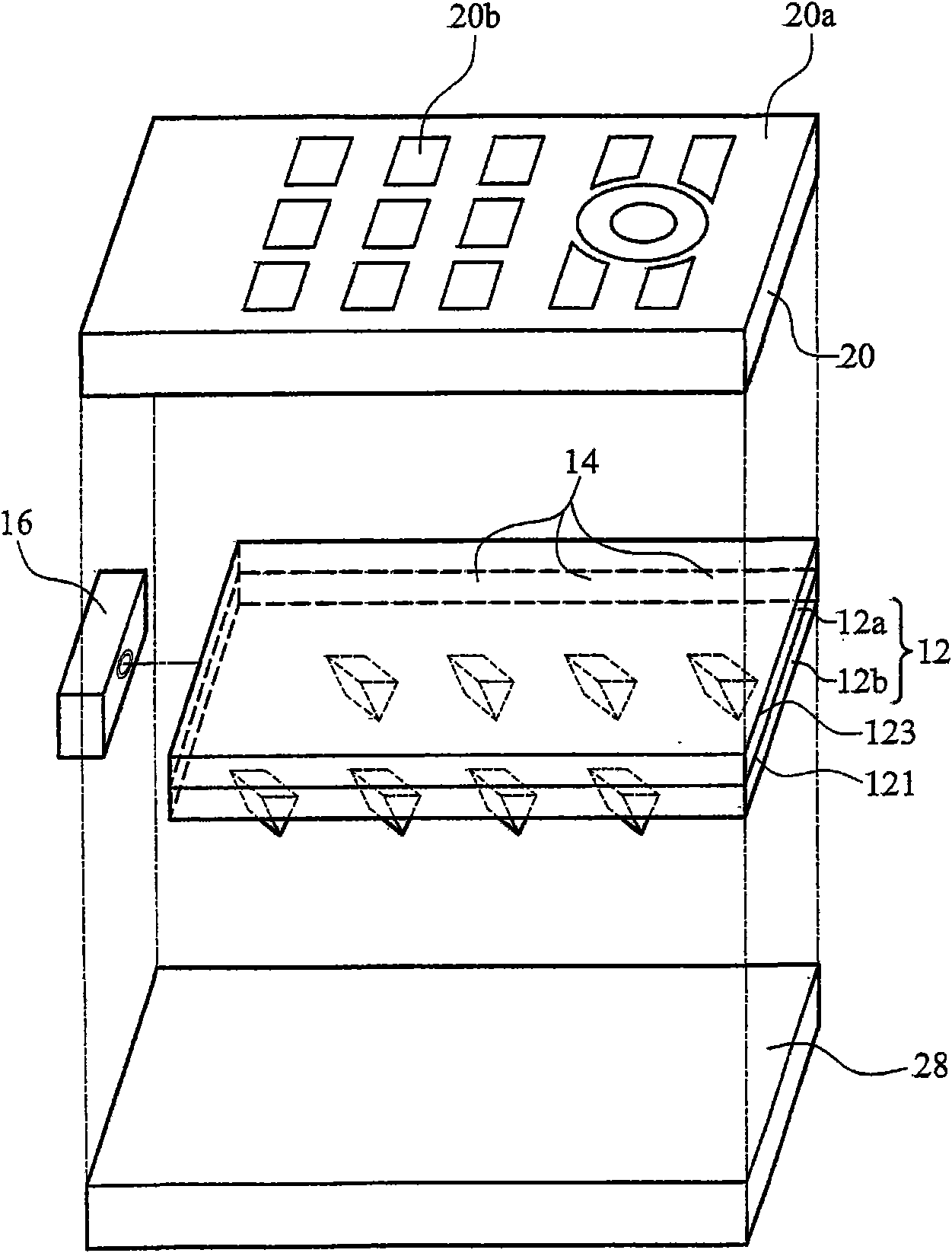

[0034] The present invention provides a light guide assembly 12, please refer to Figure 1a , which is mainly composed of a polymer substrate 12a and a UV hardening material 12b, wherein the polymer substrate 12a includes polyethylene terephthalate (polyethyleneterephthalate, PET), polycarbonate (polycarbonate, PC) or polymethyl Polymethylmethacrylate (PMMA), the selection of the base material 12a is not limited to the materials mentioned above, as long as it is a polymer with optical properties, it can be used as the polymer base material 12a of the present invention. The UV curable material 12b is mainly composed of photopolymerizable monomers and photoinitiators, such as monomers of acrylates, epoxy resins, urethanes or silanes. The photoinitiator is benzene Chloroacetone, benzoin ether or p-aminoacetophenone, but the choice of UV curing material 12b is not limited to the above-mentioned materials, in addition, different materials can be selected according to the needs of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com