Manufacturing method of stacked electrodes by winding type electrode stacking and stacked electrode thereby

A technology of electrode stacks and electrodes, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve problems such as battery life reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

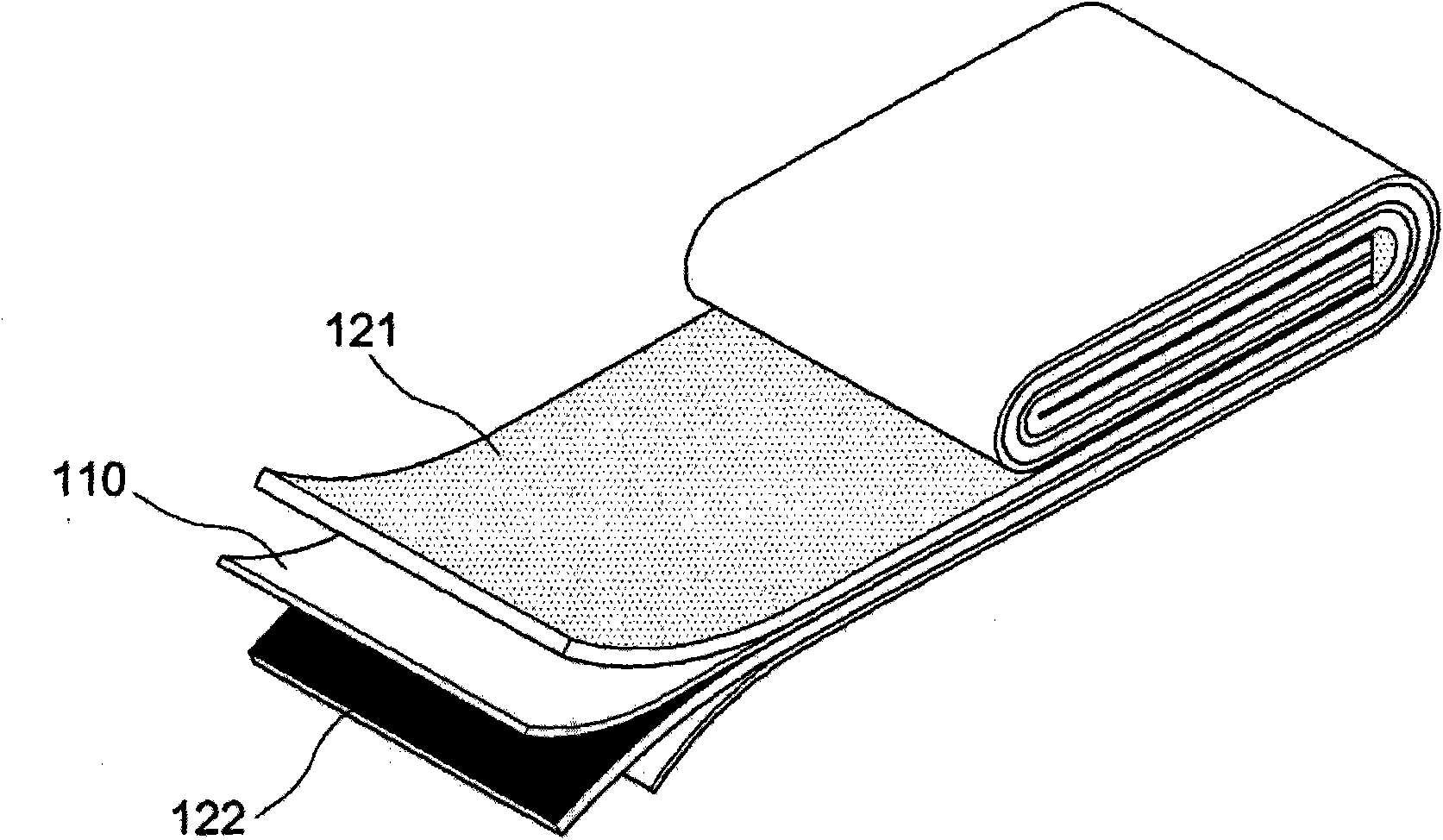

[0042] The anode electrode (i.e., the first electrode 121) is made by mixing lithium nickel cobalt manganese (LiNi x co y mn z o 2 ) (i.e. anode active material), carbon black (i.e. conductive material) and polyvinylidene fluoride PVDF (i.e. binding substance) and NMP (N-methylpyrrolidone) solvent to obtain a slurry, in the aluminum charge collector The slurry is coated on top and finally dried. The cathode electrode (i.e. the second electrode 122) was made by obtaining a slurry of the same composition as in the anode electrode composition except that graphite was used instead of lithium transition metal oxide, coated on a copper charge collector The slurry is finally dried to finish.

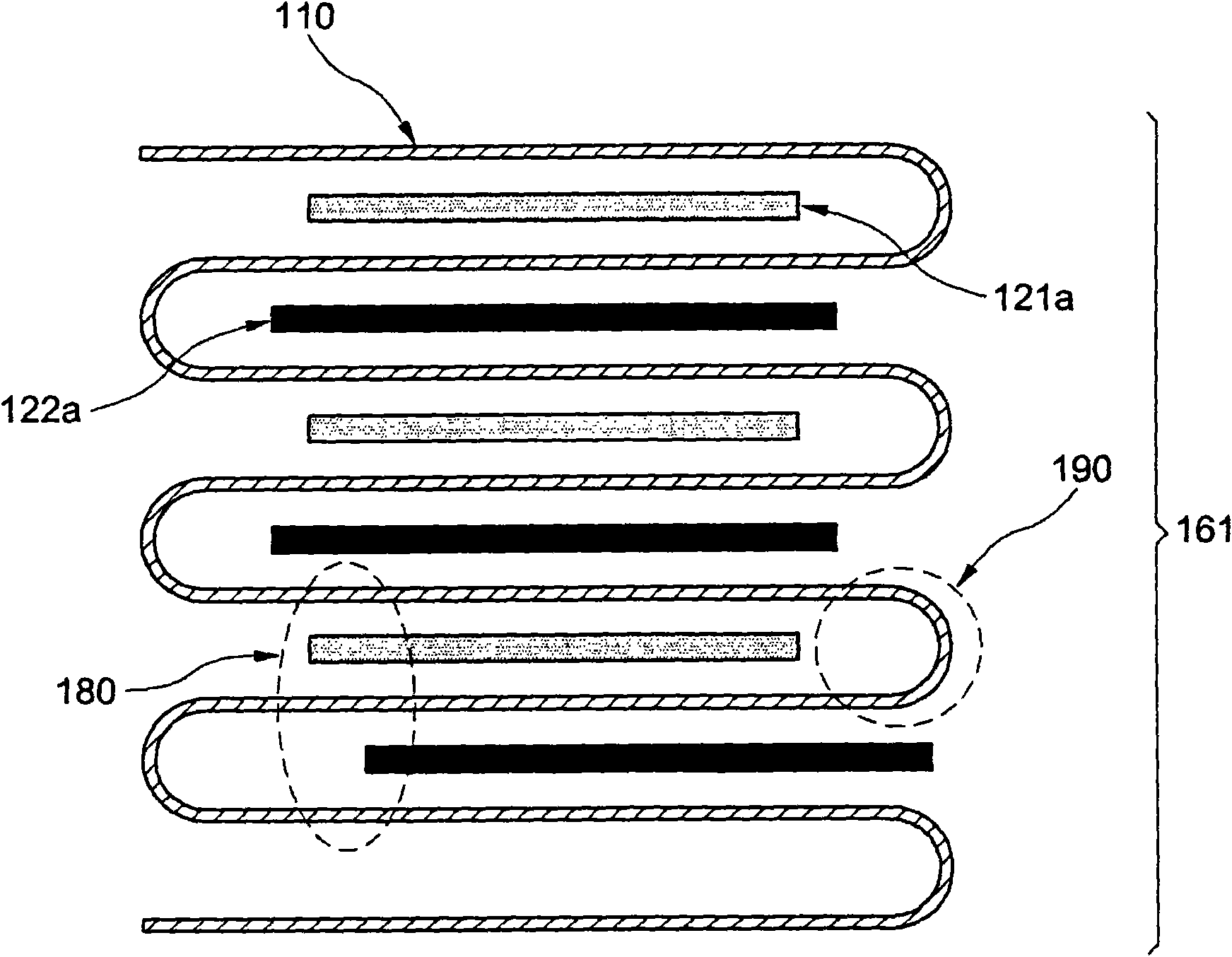

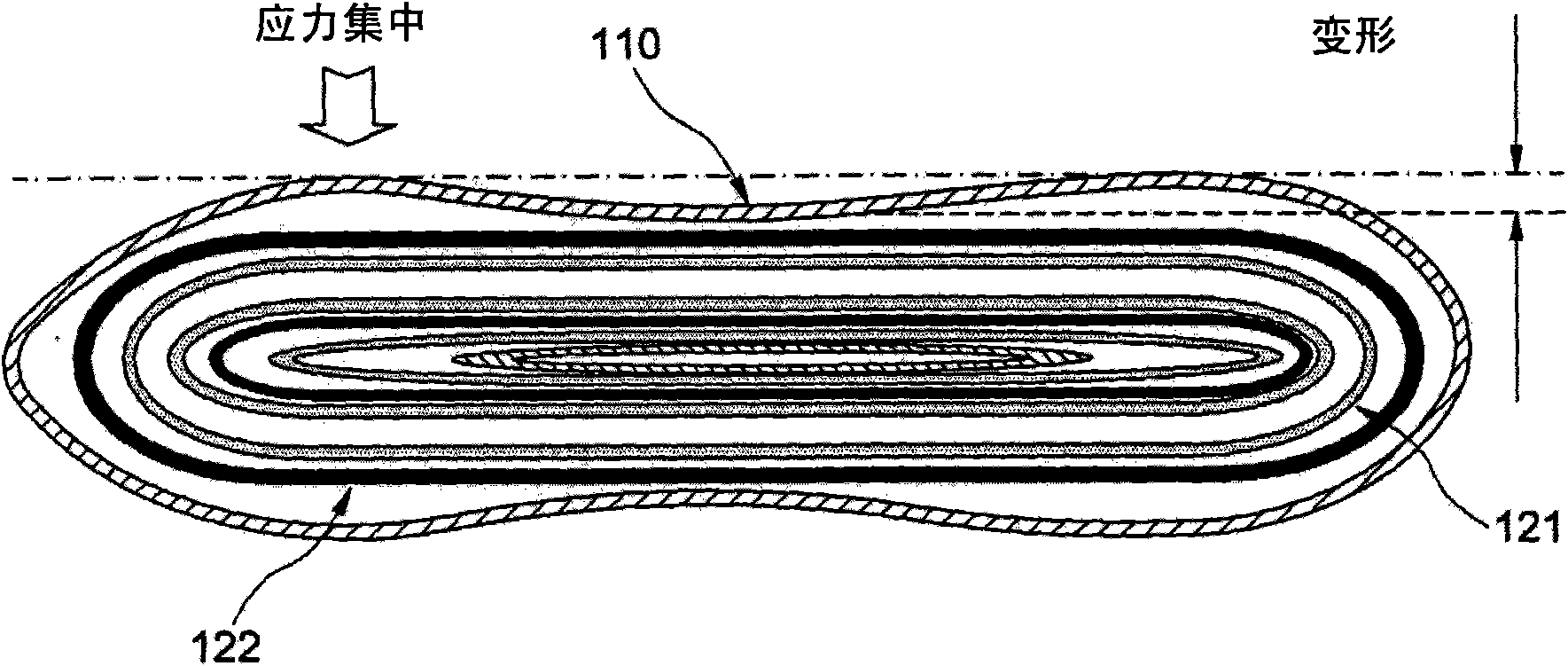

[0043] Each anode electrode and cathode electrode is stamped according to the design size, but the size design of the cathode electrode is larger than the size of the anode electrode. A porous film made of polyethylene material is used as the isolation layer 110 . The separation layer 110...

Embodiment 2

[0046] An electrode stack and a rechargeable battery using the electrode stack were fabricated in the same manner as in Example 1 above, except that the same anode and cathode electrodes as in Example 1 were used, but both ends of the separator were separated from two Release layer rolls 171 and 172 are withdrawn and joined together.

Embodiment 3

[0048] An electrode stack and a rechargeable battery using the electrode stack were manufactured in the same manner as in Example 1 above, except that the same electrode stack as in Example 1 was used, but in the process of forming the unit electrode main body, initially Stacked anode electrodes are coated and dried on only one side, as in Figure 5 shown. as from Figure 5 The innermost electrodes of the electrode assembly shown, each have only one side coated with slurry on the partial electrode 125 and 126 for the anode charge collector, but the other side of the partial electrode 125 and 126 is not coated with slurry and arranged opposite each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com