Conductive inks with metallo-organic modifiers

A metal-organic, conductive ink technology, applied in inks, printed circuits, electrical components, etc., can solve problems such as reducing the performance of solar cells and substrate pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

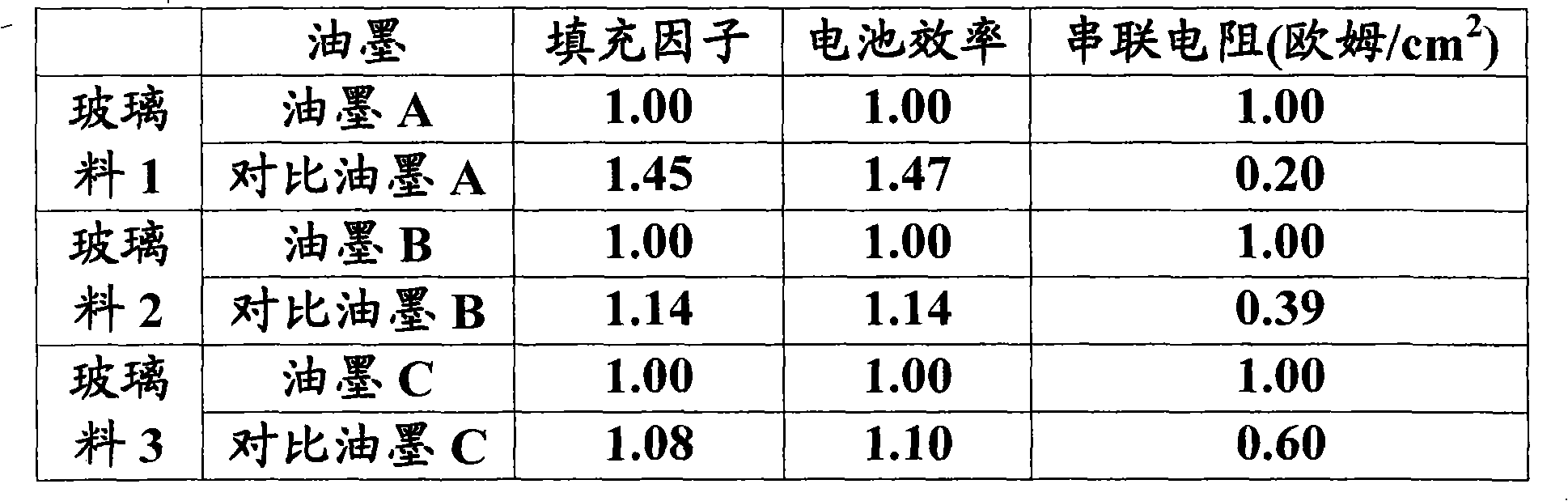

[0046] Six photovoltaic cells printed with six conductive inks (Inks A-C and Comparative Inks A-C) were tested for fill factor, cell efficiency, and series resistance to measure the performance of the device and the inks placed thereon. Inks A-C each contained silver conductive species and three different frits. The glass frit contains bismuth oxide, silicon dioxide, boron oxide and zinc oxide. Comparative Inks A-C contained silver conductive species and bismuth metallo-organic components. Comparative Ink A also contained the glass frit tested in Ink A, while Comparative Inks B and C contained the glass frit tested in Inks B and C, respectively. The performance of each photovoltaic cell was determined and is shown in Table 1. The values obtained for photocells containing comparative inks A, B, and C were normalized to the corresponding inks A, B, and C, respectively.

[0047] Table 1: Solar cell test results for conductive inks with and without metal-organic components

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com