Water treatment device and method for cleaning filtration material layer for water treatment device

A technology of water treatment device and filter material, which can be applied in the directions of oxidized water/sewage treatment, water/sludge/sewage treatment, mechanical oscillation water/sewage treatment, etc., which can solve the problems of troublesome maintenance, high cost, and low water treatment efficiency. , to save manufacturing costs, improve cleaning efficiency, and promote high-speed filtration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0163] Embodiments of the present invention will be described below.

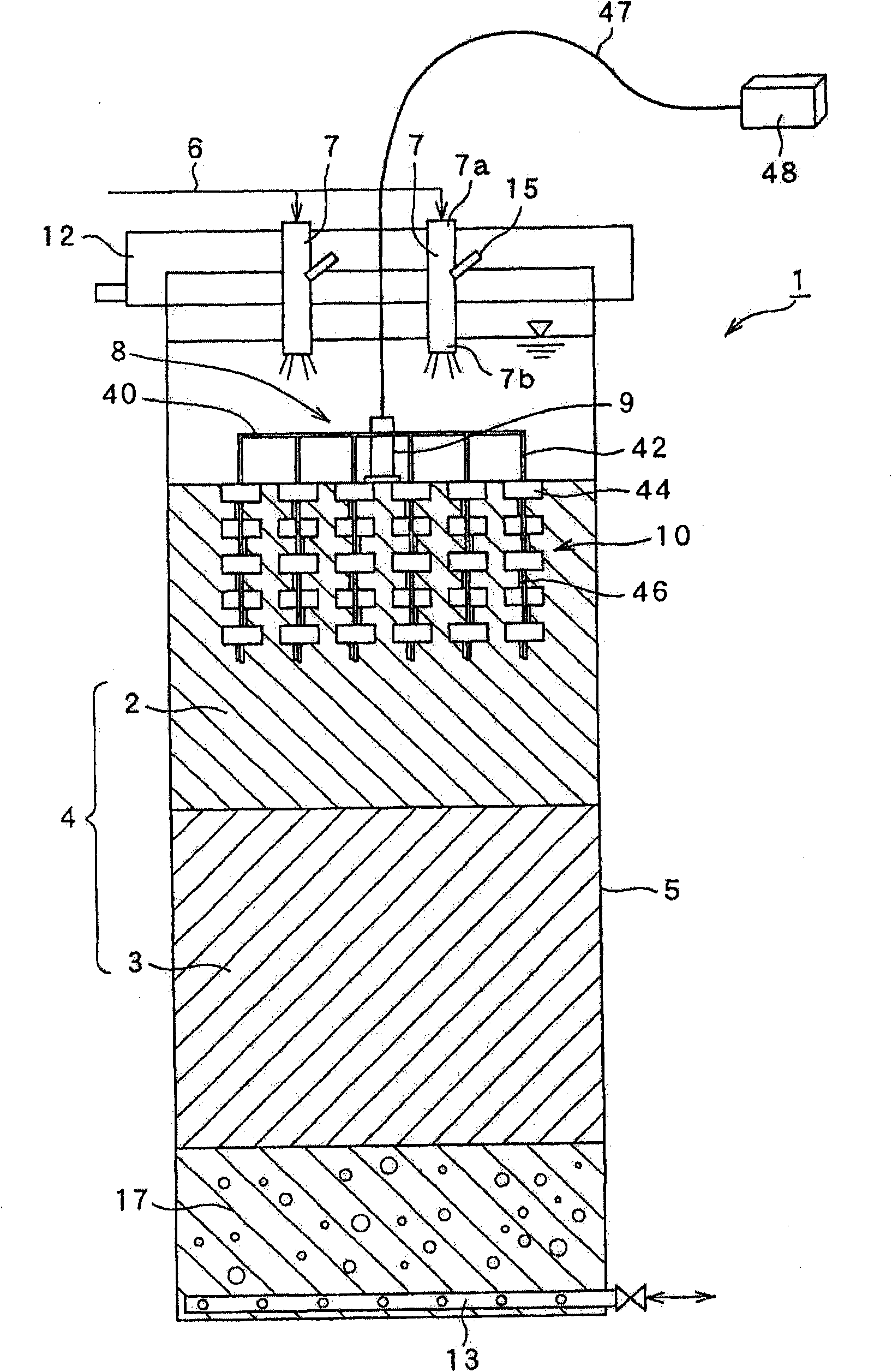

[0164] use figure 1 A water treatment device for water treatment using groundwater as raw water.

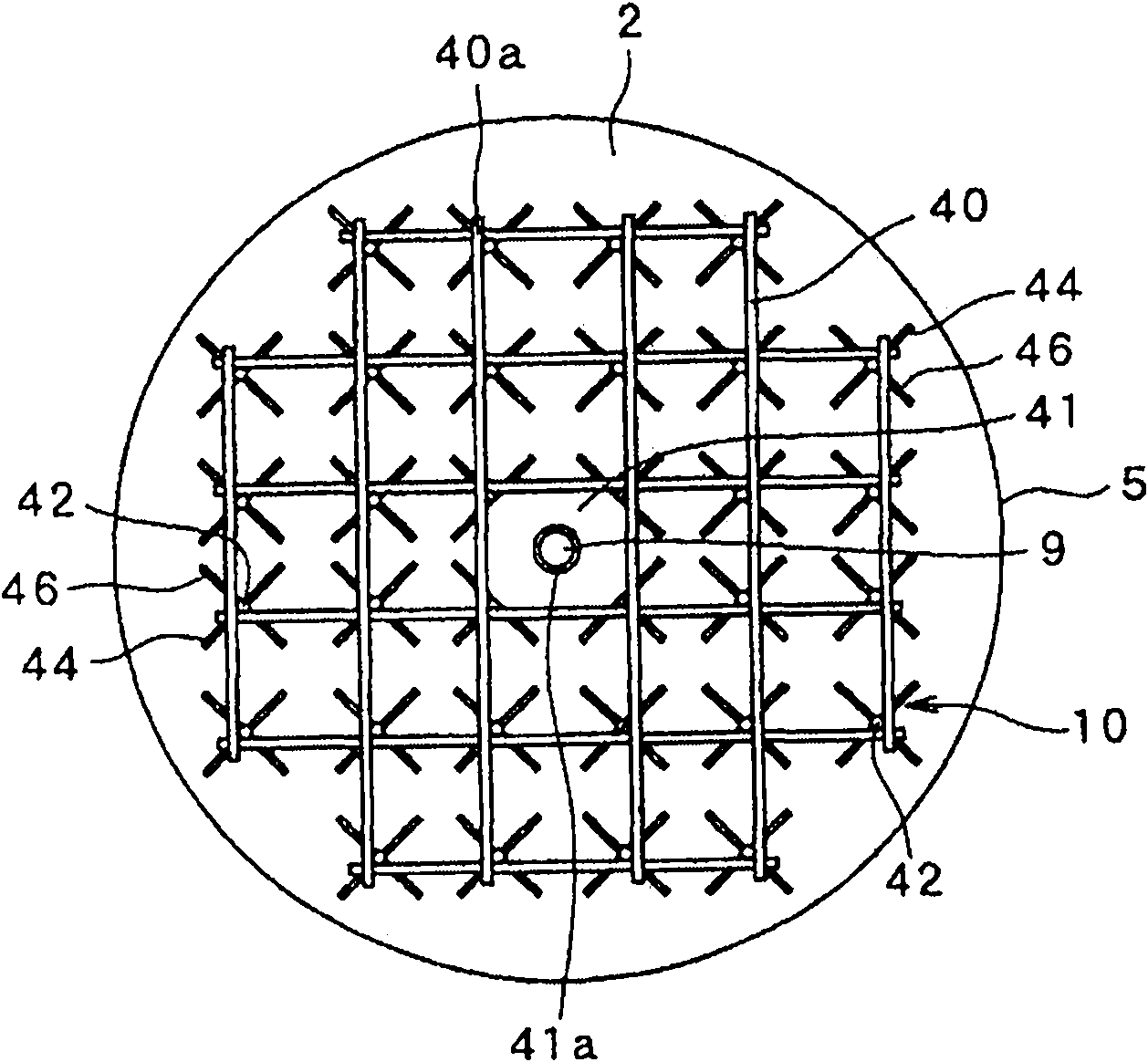

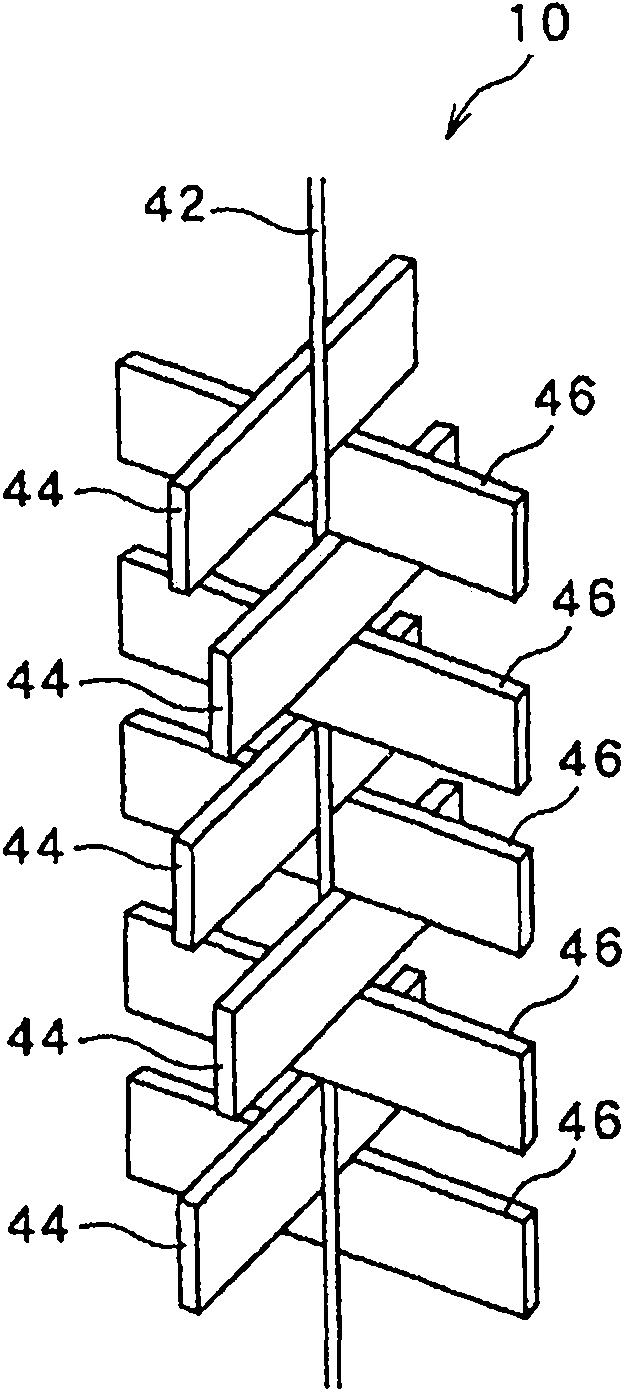

[0165] As the filter tank of the water treatment device, a circular filter tank with an inner diameter of 1200 mm in plan view was used. The distance between the vibration expansion elements 10 embedded in the upper layer (the length of one side of a square formed by four vibration expansion elements 10 ) was 150 mm. The configuration method of the vibration expansion element 10 uses Figure 6 method shown. The length of the support rod of the vibratory expansion element 10 is 640mm.

[0166] One commercially available concrete vibrator was used as the vibrating element 9 , and this vibrating element 9 was arranged at the center of the frame body 40 . The power source of the vibrating element uses commercial AC current, and the frequency of the current is converted to 400Hz by a frequency converter, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| vibrational frequency (mechanical) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com