Automatic packaging machine for emulsion explosive cartridge

An automatic packaging machine and emulsion explosive technology, applied in explosives, explosives processing equipment, offensive equipment and other directions, can solve the problems of affecting performance, hidden dangers of explosives safety, difficult to arrange multiple stations, etc., to avoid metal friction and impact, Avoid unsafe factors, strong effect of continuous charging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate the understanding of those skilled in the art, the structural principle of the present invention will be further described in detail below in conjunction with specific embodiments and drawings:

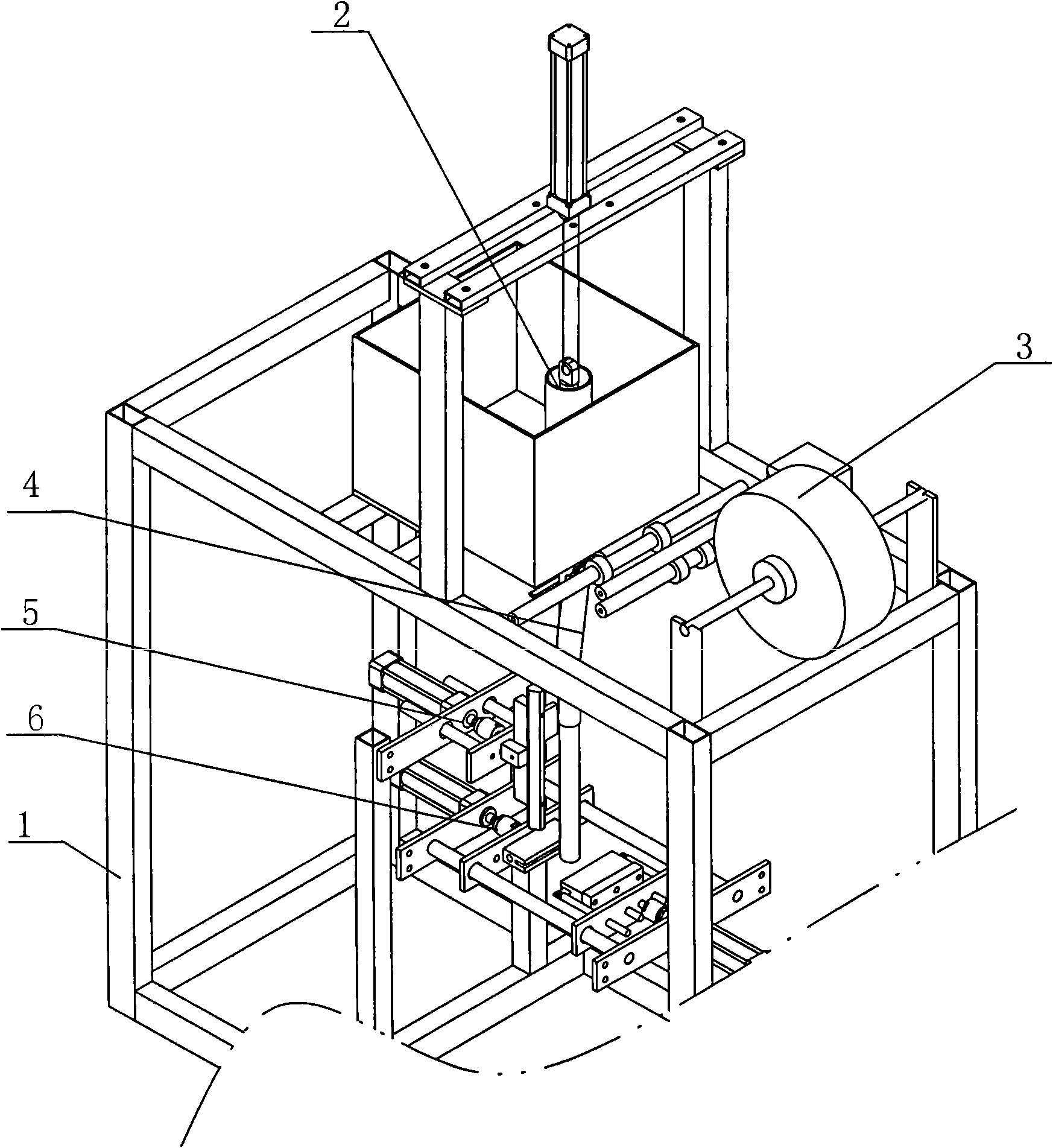

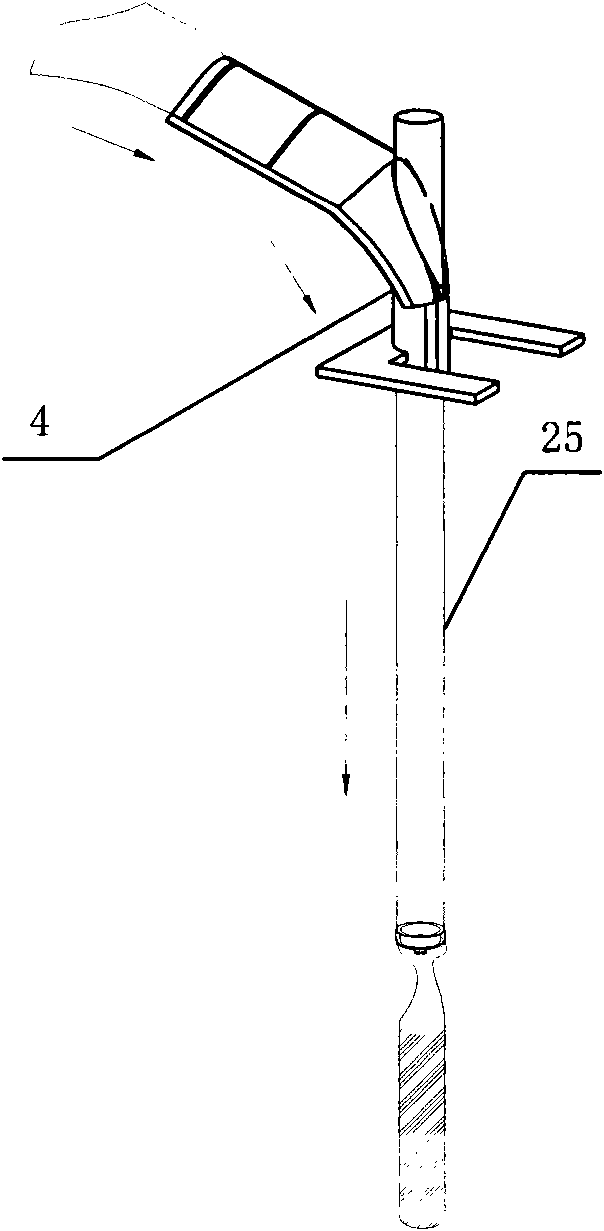

[0025] Such as figure 1 As shown, an embodiment of an automatic packaging machine for emulsion explosives rolls includes a frame 1, a quantitative filling device 2, a film releasing device 3, a film tube forming device 4, a vertical welding device 5, and a horizontal welding device 6. The quantitative filling device 2, the film releasing device 3, the film tube forming device 4, the vertical welding device 5, and the horizontal welding device 6 are installed on the frame 1 respectively.

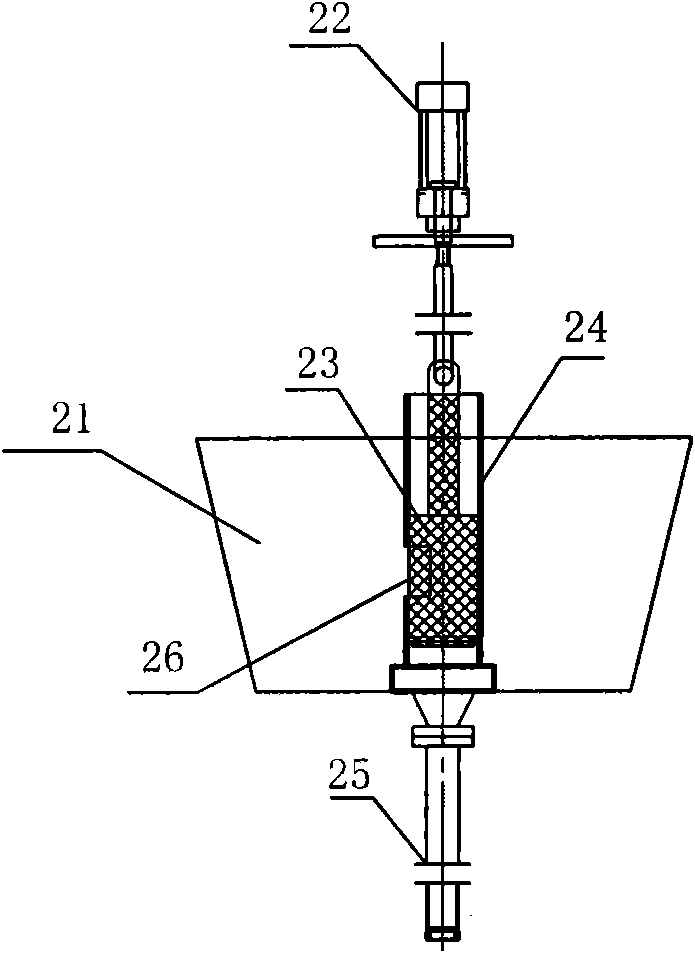

[0026] Such as figure 2 As shown, the quantitative filling device 2 includes a hopper 21, a cylinder 22, a piston 23, a cylinder 24, and a discharge tube 25. The hopper 21 is installed on the frame 1, and the cylinder 24 is in the hopper 21 and the frame 1 Vertical installat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com