Method for preparing pectin by high static pressure technology

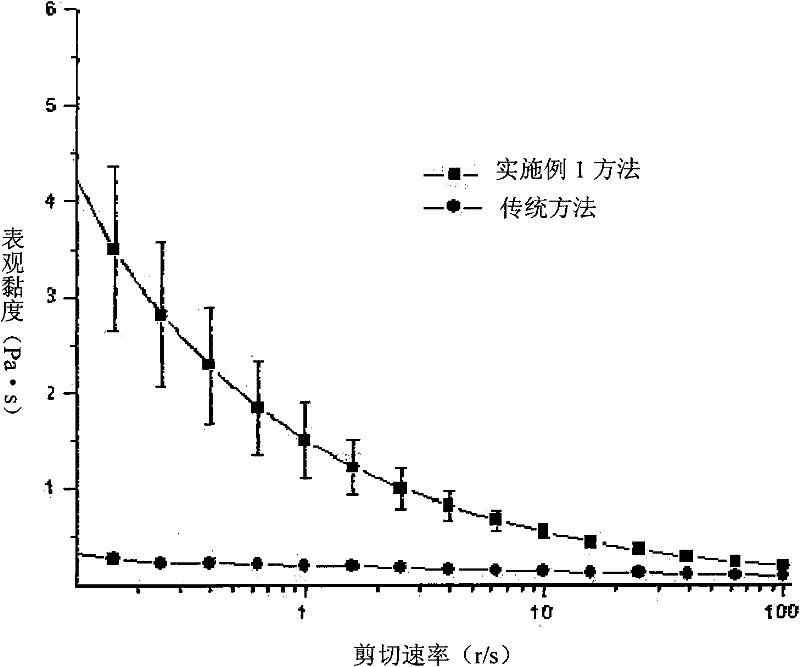

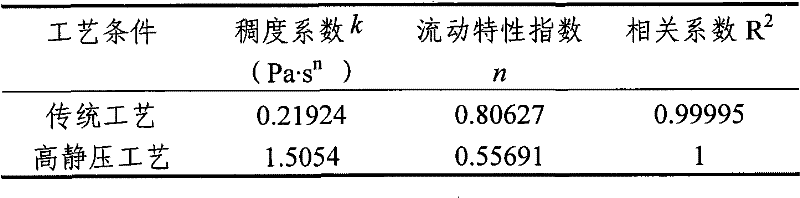

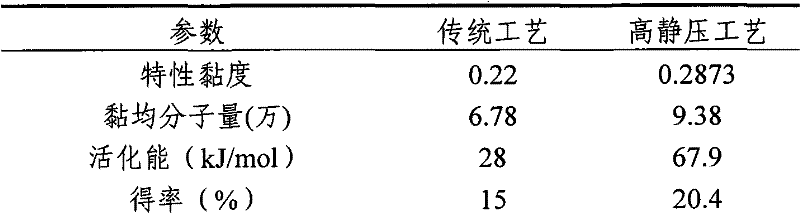

A high static pressure and pectin technology is applied in the field of preparing pectin by using the high static pressure technology, which can solve the problems of destroying pectin molecular chains, poor pectin yield and quality, and increasing production costs, thereby improving market competitiveness. , The effect of ensuring yield and quality, and reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Pretreatment of raw materials: fresh citrus peels were inactivated in a water bath at 90°C for 5 minutes, dried at 40°C, and then crushed to pass through a 60-mesh sieve; The aqueous solution is mixed according to the mass volume ratio of 1:20 (g / ml), and then vacuum-packed with a PAPE vacuum bag, and the vacuum degree in the package is 0.1MPa;

[0030] The acidic aqueous solution refers to adjusting pH=1.5 with hydrochloric acid in deionized water;

[0031] 2) Extraction of pectin under high static pressure: Preheat the high static pressure equipment until the outer wall temperature is 55°C (processing temperature), then put the above-mentioned vacuum-packed mixture into the high static pressure equipment, and the processing pressure is 500MPa. Processing temperature and processing pressure, high static pressure processing for 10 minutes, so as to achieve the purpose of pectin dissolution from raw materials;

[0032] 3) Post-treatment of pectin: after the high stat...

Embodiment 2

[0034] 1) Pretreatment of raw materials: inactivate fresh citrus peels in a water bath at 85°C for 10 minutes, dry them at 40°C, and then crush them through a 60-mesh sieve; press the crushed citrus peels with an extract of pH=1.5 The mass volume ratio is 1:20 (g / ml) and mixed, and then vacuum-packed with PAPE vacuum packaging bag, and the vacuum degree in the package is 0.1MPa;

[0035] The acidic aqueous solution refers to adjusting pH=1.5 with hydrochloric acid in deionized water;

[0036] 2) Extraction of pectin under high static pressure: Preheat the high static pressure equipment until the outer wall temperature is 55°C (processing temperature), then put the above-mentioned vacuum-packed citrus peels into the high static pressure equipment, the processing pressure is 400MPa, keep The treatment temperature and treatment pressure, high static pressure treatment for 10 minutes, so as to achieve the purpose of pectin dissolution from raw materials;

[0037] 3) Post-treatmen...

Embodiment 3

[0040] 1) Pretreatment of raw materials: inactivate fresh apple peel pomace in a water bath at 100°C for 3 minutes, dry at 40°C, and then pulverize until passing through a 60-mesh sieve; mix the crushed apple peel with pH=1.5 acidic The aqueous solution is mixed according to the mass volume ratio of 1:20 (g / ml), and then vacuum-packed with a PAPE vacuum packaging bag, and the vacuum degree in the packaging bag is 0.1MPa;

[0041] The acidic aqueous solution refers to adjusting pH=1.5 with hydrochloric acid in deionized water;

[0042] 2) Extraction of pectin under high static pressure: Preheat the high static pressure equipment until the outer wall temperature is 50°C (processing temperature), then put the above-mentioned vacuum-packed mixture into the high static pressure equipment, and the processing pressure is 300MPa, keep the Processing temperature and processing pressure, high static pressure processing for 15 minutes, so as to achieve the purpose of dissolving pectin fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com