Multifunctional energy saving biological fermentation furnace

A bio-fermentation and multi-functional technology, applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biomass post-treatment, etc., can solve the problem of dead angle, long production cycle, insufficient fermentation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

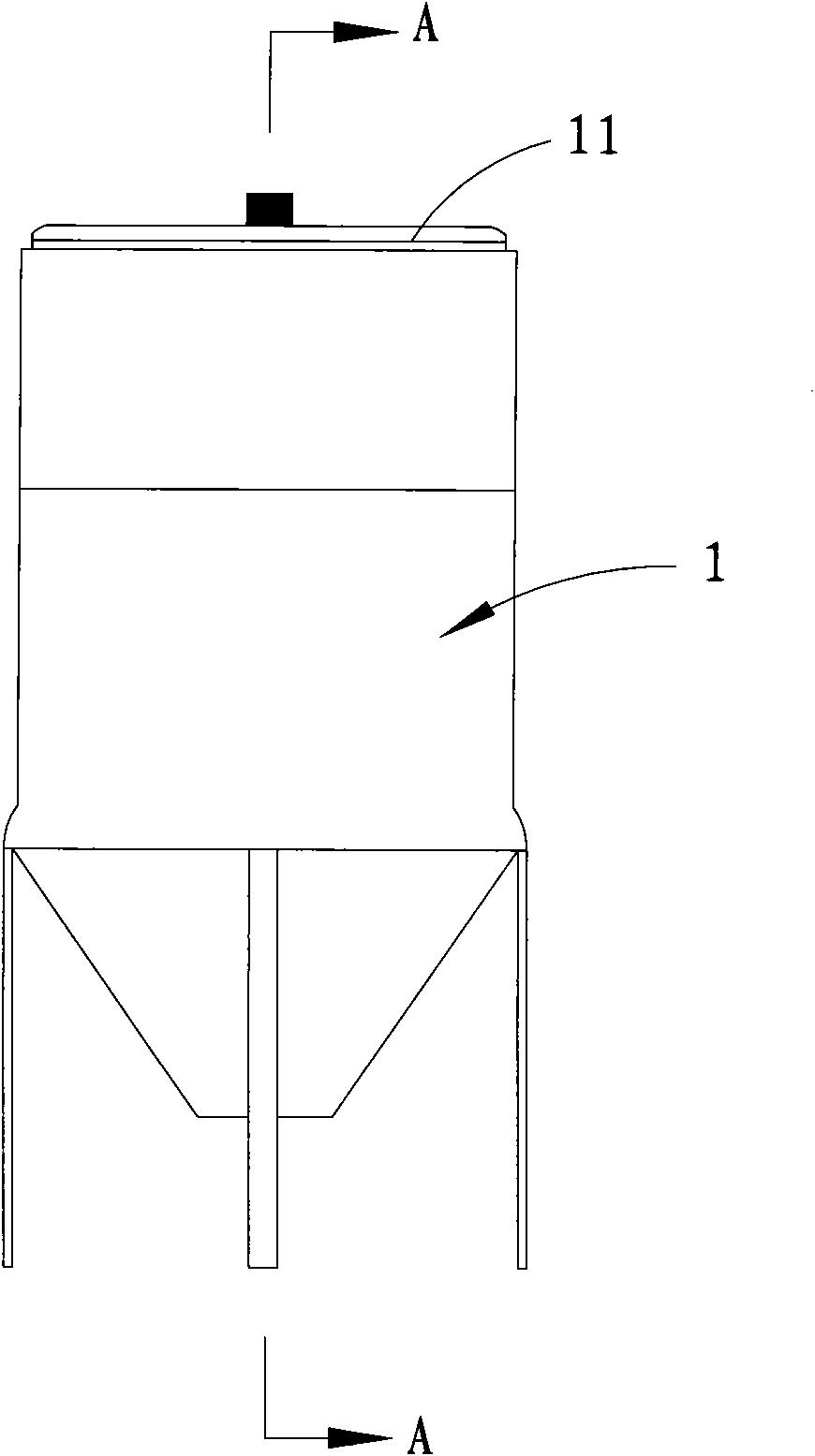

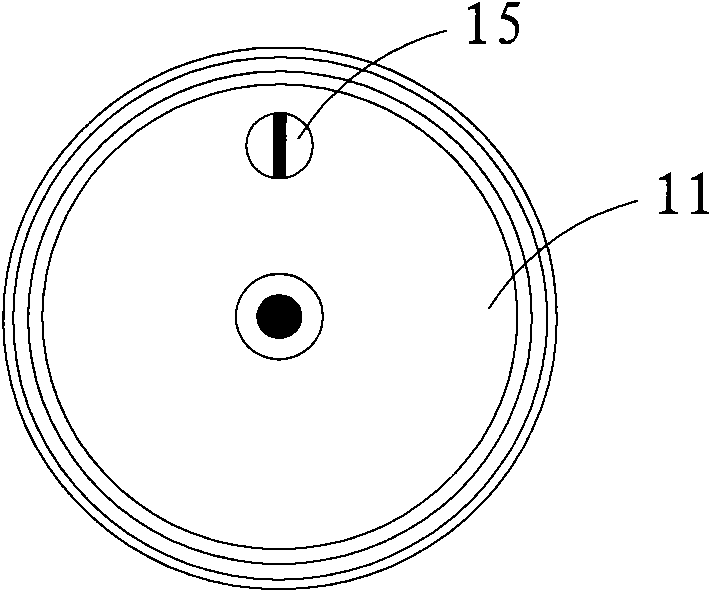

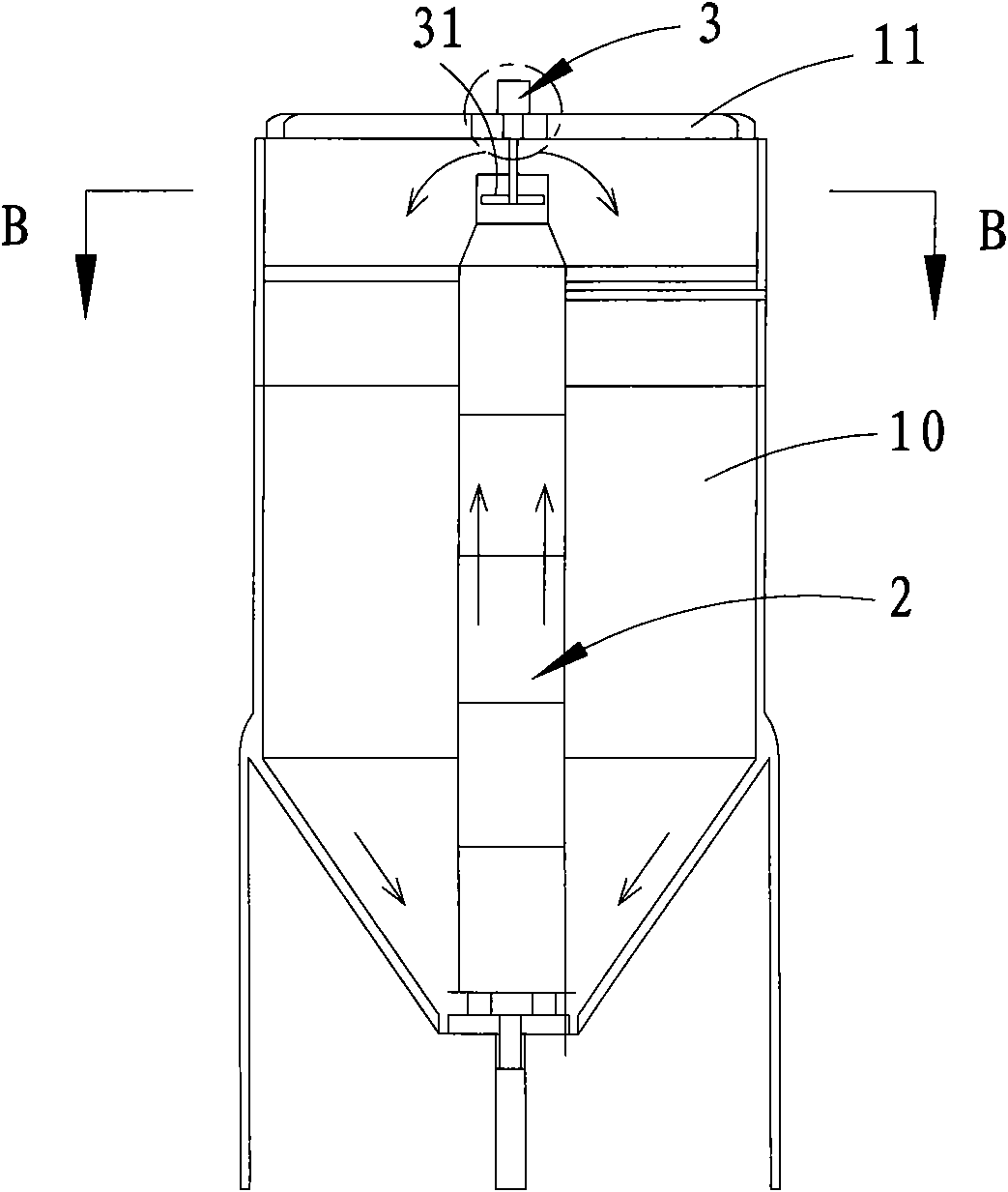

[0031] Example: see Figure 1 to Figure 7 , a multifunctional energy-saving biological fermentation furnace, comprising an outer tank 1, an inner tank and a liquid extraction stirring mechanism, wherein:

[0032] Outer tank 1 is a container for accommodating fermented liquid;

[0033] The inner tank 2 extends along the central axis of the outer tank to the bottom of the cavity of the outer tank, and the bottom of the inner tank 2 is provided with a communication hole communicating with the cavity of the outer tank 1;

[0034] The liquid extraction and stirring device 3 is installed on the top of the outer tank, and the liquid extraction mechanism 31 of the liquid extraction and stirring device 3 is arranged at the top outlet of the inner tank 2;

[0035] When the extraction and stirring device works, the fermented liquid in the inner tank 2 is subjected to an upward lifting force and overflows from the outlet at the top of the inner tank 2 into the cavity 10 of the outer tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com