Dry-submarine dual-purpose motor system

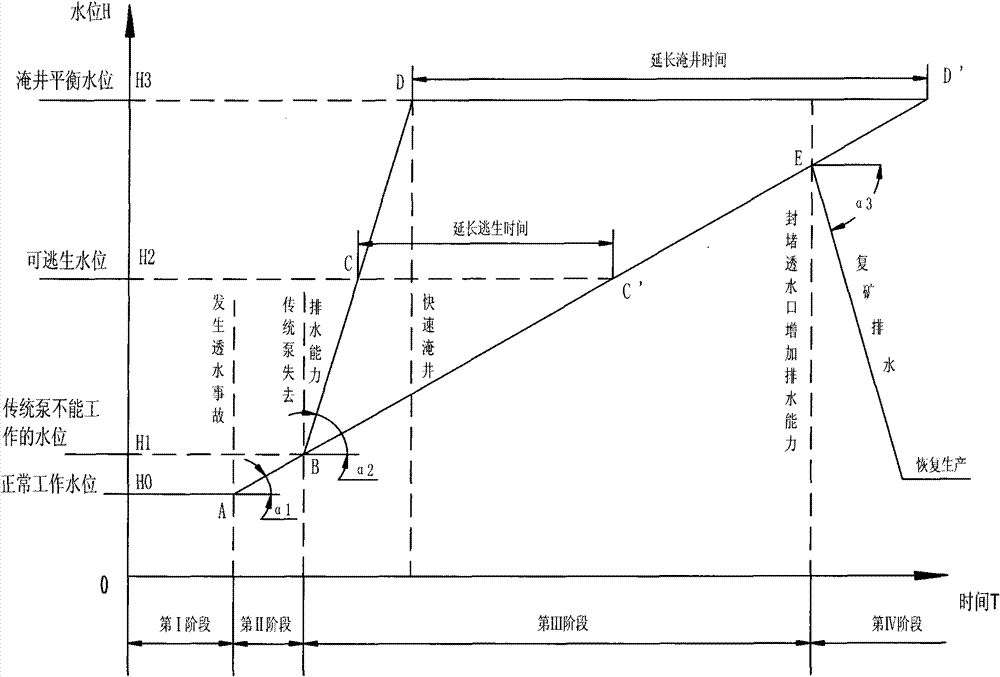

A motor and dual-purpose technology, applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve problems such as rising water levels, flooded mines, and failure of pump motors to achieve the effect of ensuring safe work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

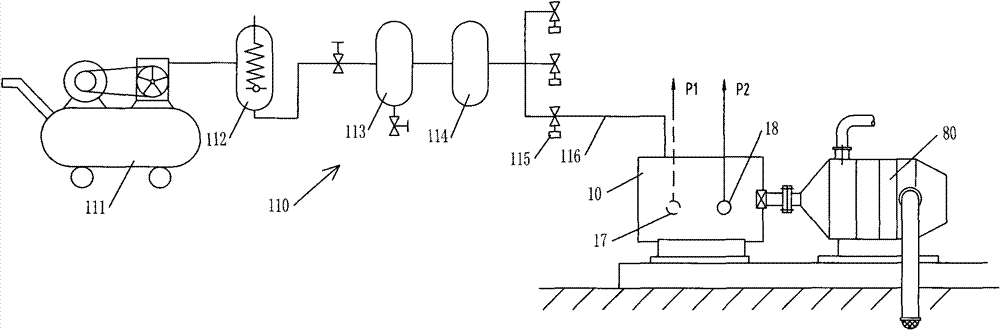

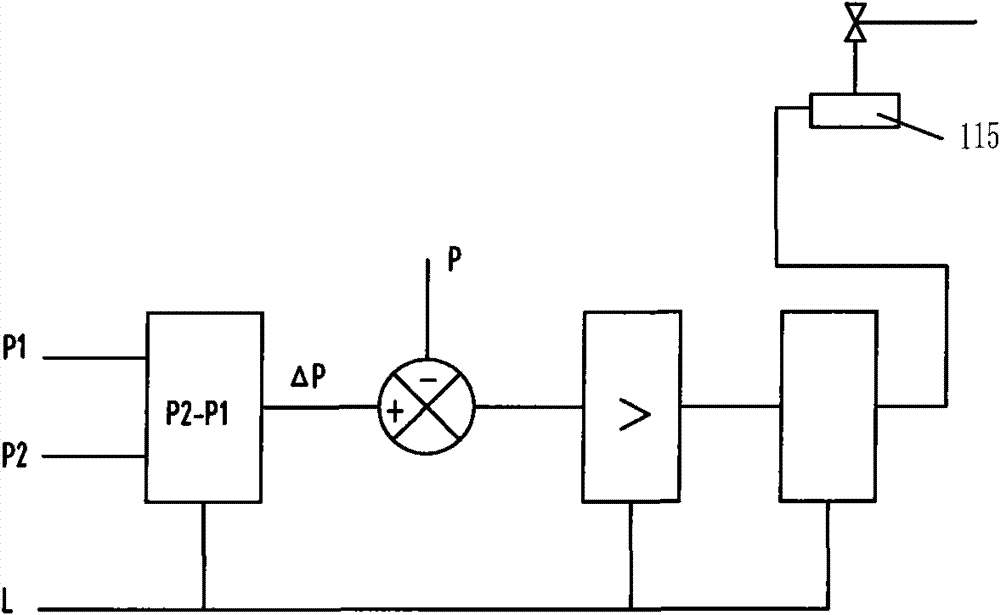

[0012] combine Figure 5 , a dry-submersible dual-purpose electric motor system, including a motor 10, the motor 10 includes a rotor 15A and a stator 15B, the stator 15B is fixed on the inner wall of a barrel-shaped inner casing 13, and the rotor 15A is coaxially connected with the output shaft 14 as a whole, Both ends of the output shaft 14 extend outward through the front and rear end covers 13A, 13B provided at both ends of the inner housing 13, and a bearing and sealing assembly 100 is provided between the output shaft 14 and the front and rear end covers 13A, 13B; The outer shell 11 is sheathed on the outside of the inner shell 13, and the cold and heat exchanger is arranged in the axial direction in the ring-shaped cavity surrounded by the outer shell 11 and the inner shell 13; the inflow end of the cold and heat exchanger, the internal passage And the outflow end communicates with the surrounding working environment of the equipment to form an outer circulation path; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com