Making method of single-side double contact flexible circuit board

A flexible circuit board, single-sided double-contact technology, applied in the direction of printed circuit manufacturing, printed circuit, printed circuit components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

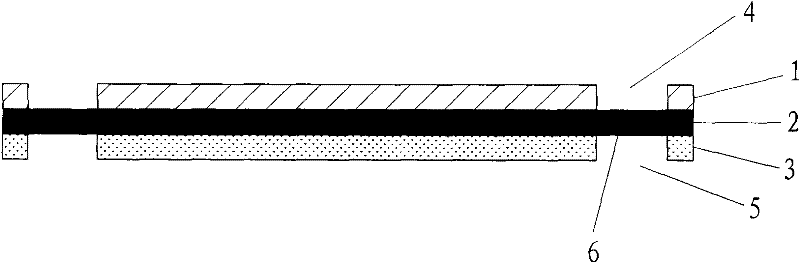

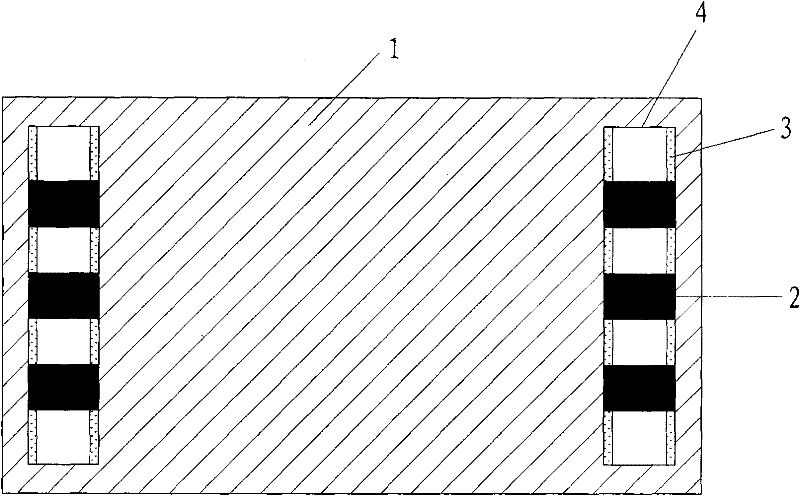

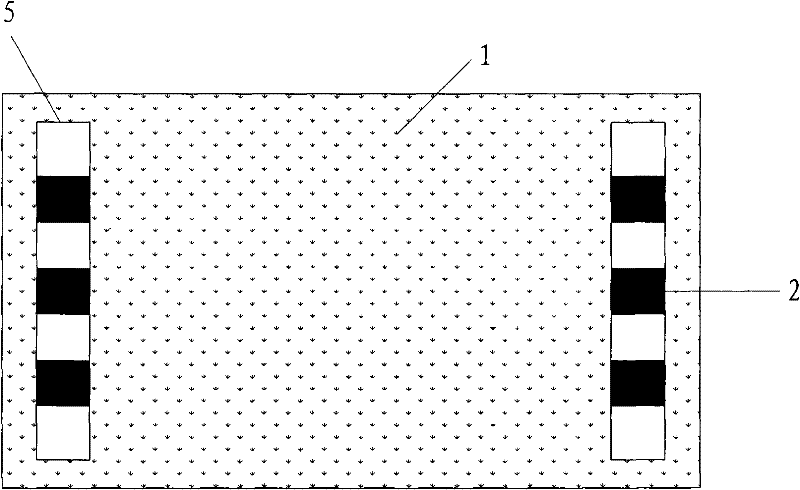

[0026] Such as Figure 5 , Figure 6 , Figure 7 As shown, a single-sided double-contact flexible circuit board disclosed by the present invention includes a base material layer 30, a copper foil layer 20, and a cover film 10. The base material layer 30 and the cover film 10 are respectively provided with a bottom base material opening 50 and a cover film 10. Openings 40 in the top cover film to form gold fingers 60 that can be in contact with the outside world on both sides; the openings 50 of the bottom substrate are spaced apart from the corresponding gold fingers 60, and the size of each bottom substrate opening 50 is smaller than the size of the top cover film 10 finger area .

[0027] Cooperate Figure 8 As shown, the single-sided double-contact flexible circuit board of the present invention and its manufacturing method specifically include the following steps:

[0028] (1) Cutting: Cut the materials used according to the specifications and sizes required for produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com