High strength galvanized steel sheet with excellent formability and method for manufacturing the same

A hot-dip galvanized steel sheet with excellent workability. It is used in manufacturing tools, heat treatment furnaces, heat treatment equipment, etc. It can solve the problems of increased hardness difference and poor stretch flangeability during hole reaming, so as to promote weight reduction. , The effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

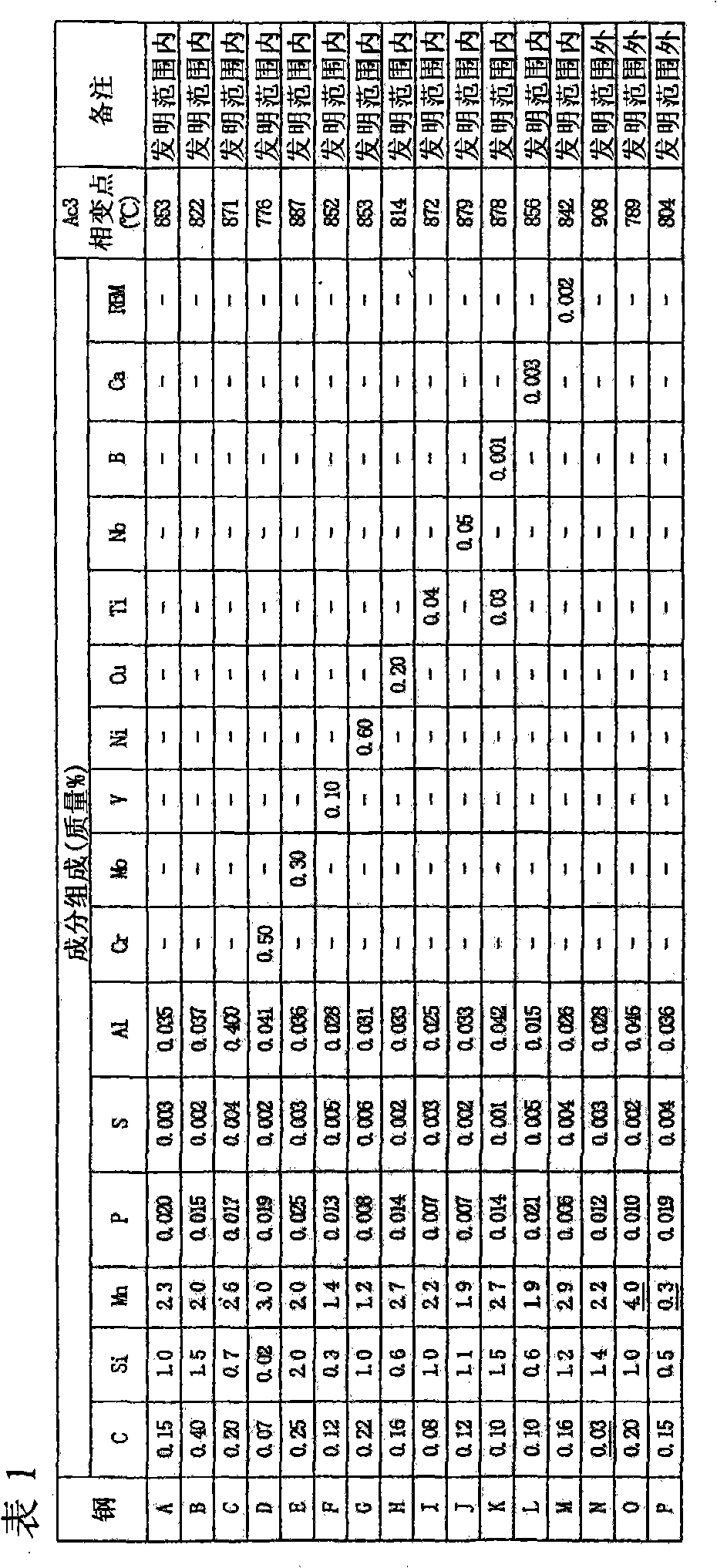

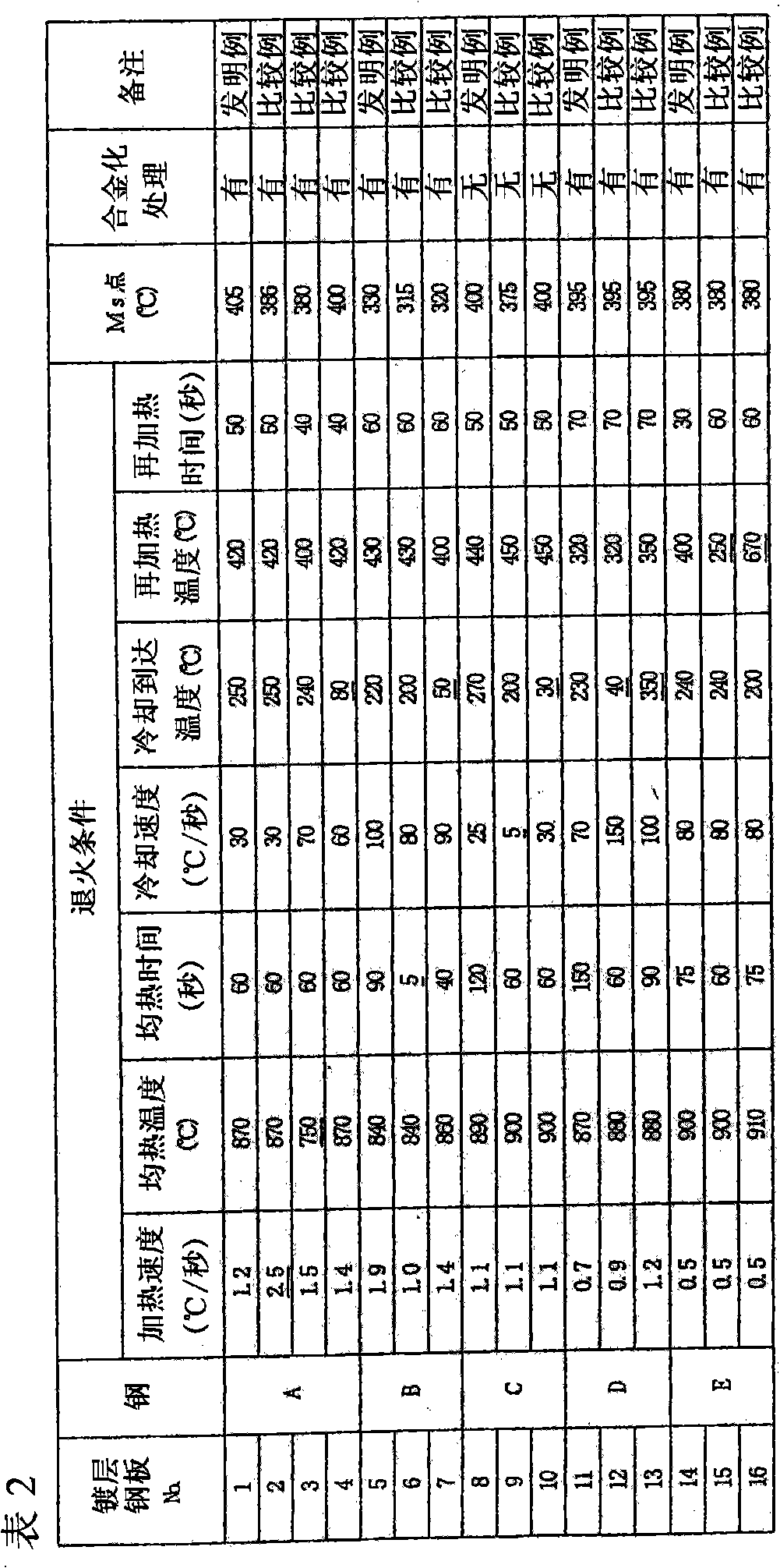

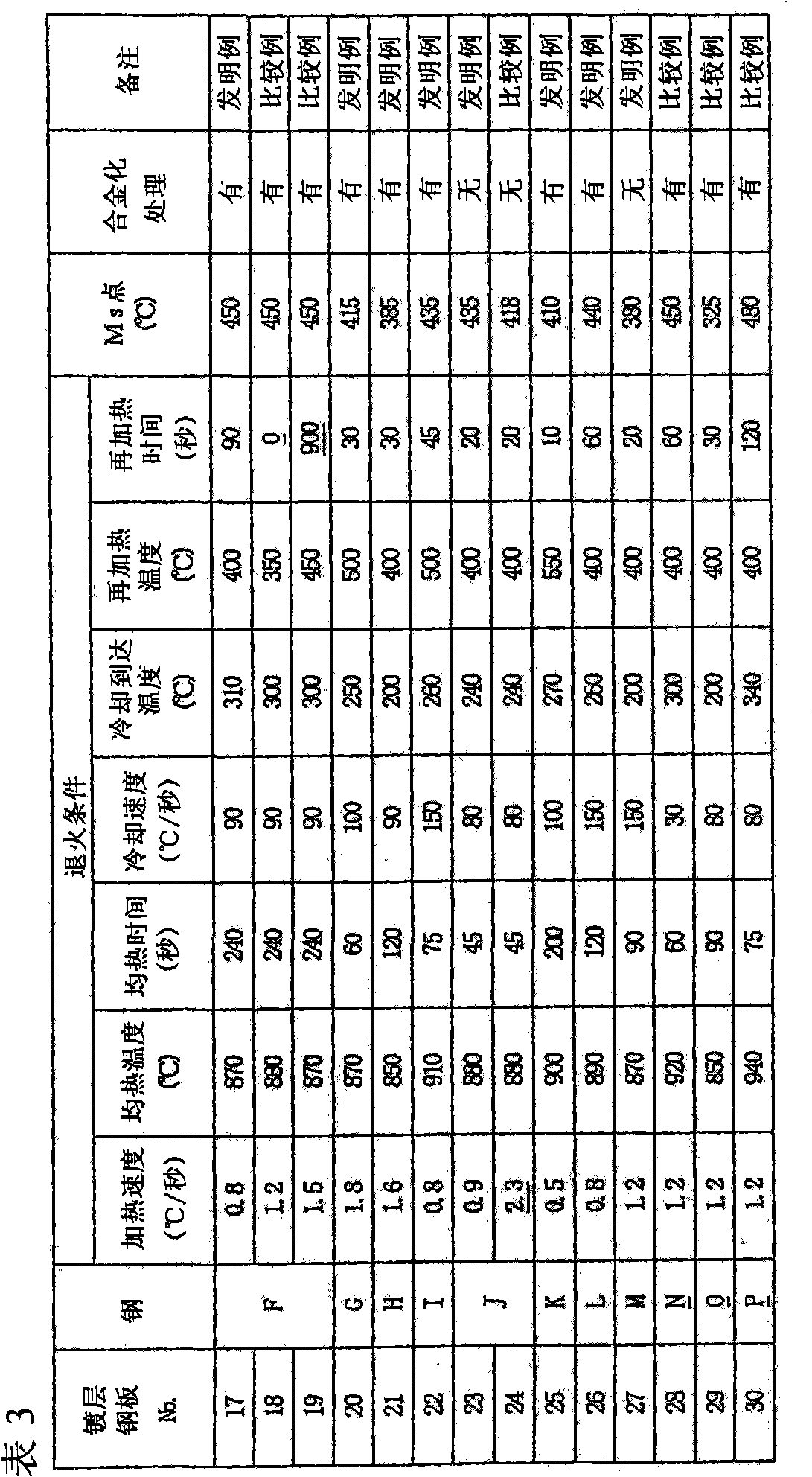

[0074] Steels A to P with the composition shown in Table 1 were smelted in a converter, and cast into slabs by continuous casting, hot rolled at a finish rolling temperature of 900°C to a plate thickness of 3.0mm, and cooled at 10°C / sec after rolling. Cooling at a high speed and coiling at a coiling temperature of 600°C. Next, after pickling, it is cold rolled to a plate thickness of 1.2 mm, annealed in the annealing conditions shown in Table 2 and 3 through a continuous hot-dip galvanizing production line, and then immersed in a plating bath at 460 ° C to form a thickness of 35 ~ 45g / m 2 The coated layer was alloyed at 520° C. and cooled at a cooling rate of 10° C. / second to produce coated steel sheets 1 to 30. In addition, as shown in Tables 2 and 3, alloying treatment was not performed on some plated steel sheets. Then, with respect to the obtained plated steel sheet, the area ratios of ferrite, martensite, and tempered martensite, and the ratio of retained austenite were m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com