Industrial flue gas treatment method and system thereof

A technology for industrial flue gas and flue gas, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of large investment, high operating costs, and low denitrification efficiency of selective catalytic reduction methods, and achieve the realization of recycling Utilization and comprehensive utilization, saving resources, and high denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

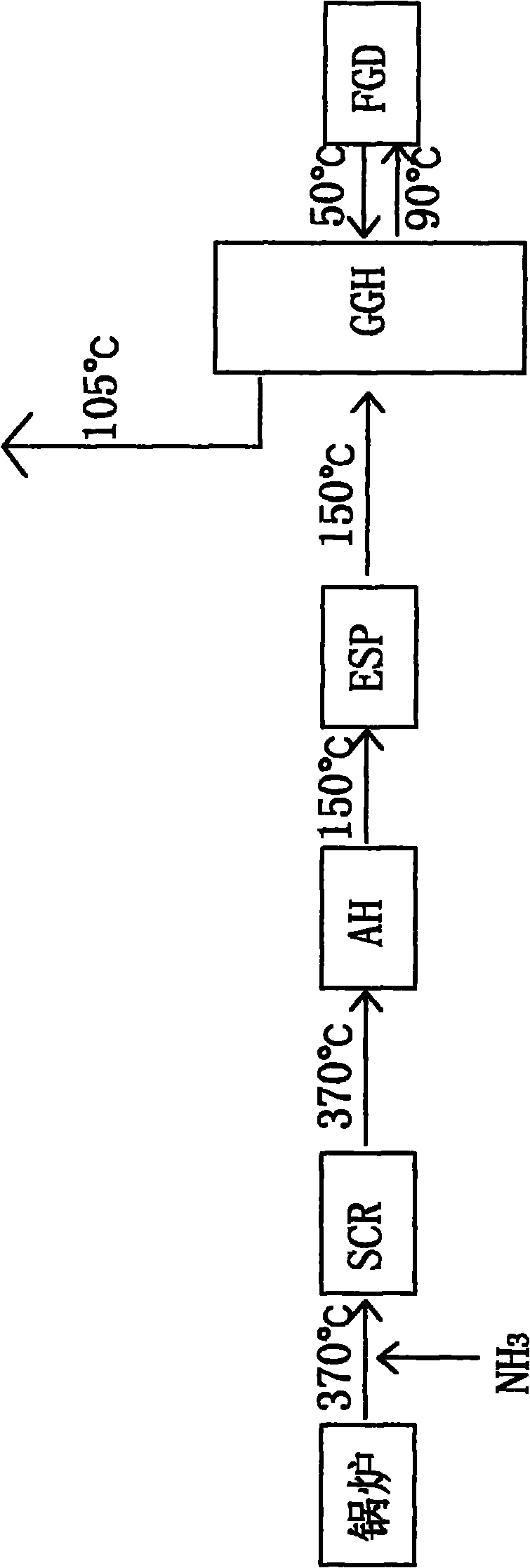

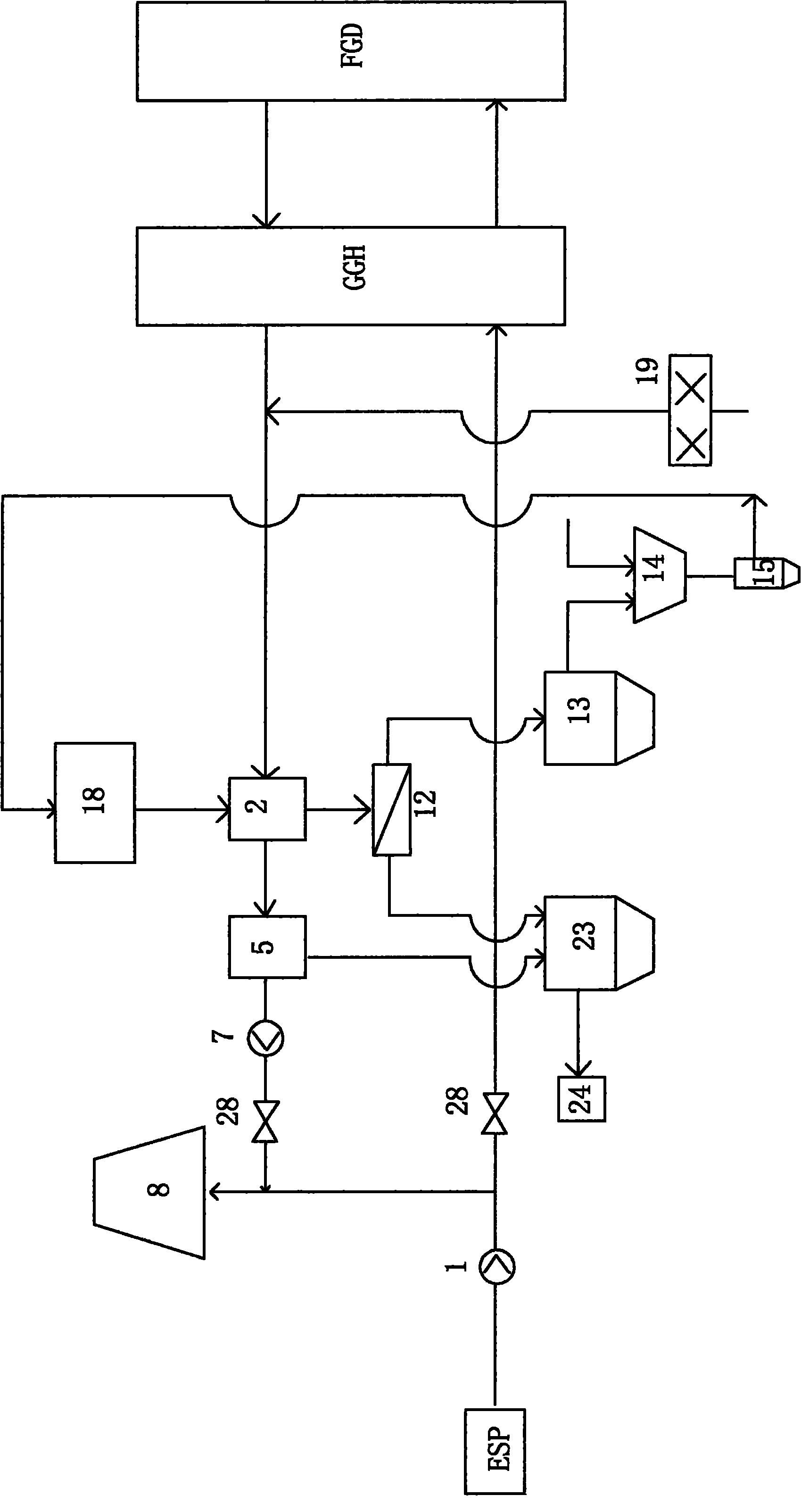

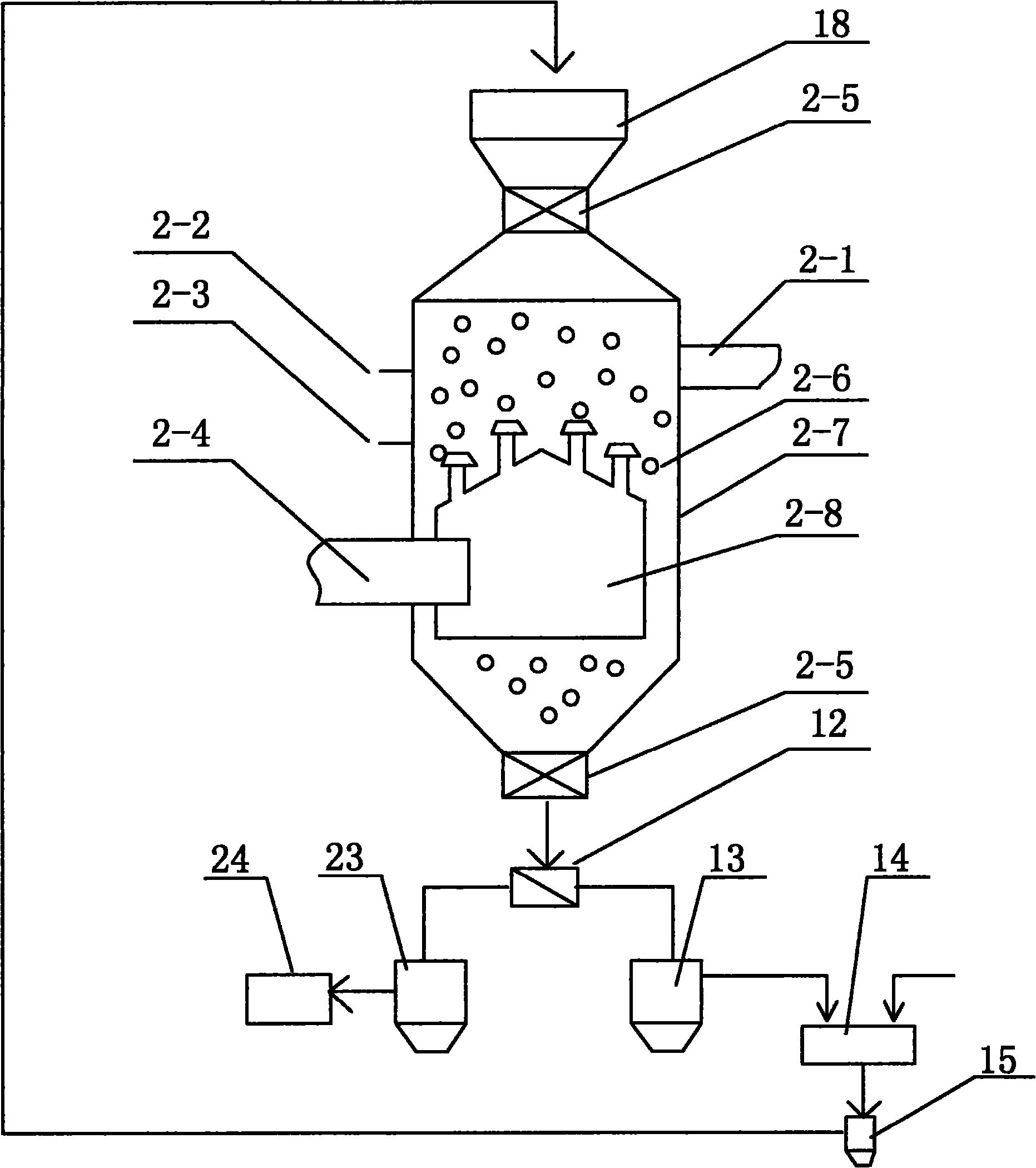

[0022] In order to develop a denitrification process that conforms to China's national conditions, has high denitrification efficiency, obvious denitrification effect, and low cost, the present invention proposes a method and supporting system for industrial flue gas treatment. The technical solution adopted is: an industrial flue gas The treatment method includes two processes of desulfurization and denitrification. In the denitrification process, nitrogen oxides are cracked to generate nitrogen by means of a catalyst. In particular, the catalyst used is optimized active coke.

[0023] In the technical solution of the present invention, the process of using optimized activated coke for denitrification is as follows: the flue gas after desulfurization is introduced into the denitrification device; the flue gas uses optimized active coke as a catalyst in the denitrification device, and the process temperature is 70-150 ° C The denitrification treatment is carried out in an envir...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap