Preparation method of plate high-temperature alloy casting with high complexity

A complex and high-temperature alloy technology, which is applied in the field of high-temperature alloy casting and can solve problems such as the difficulty of castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

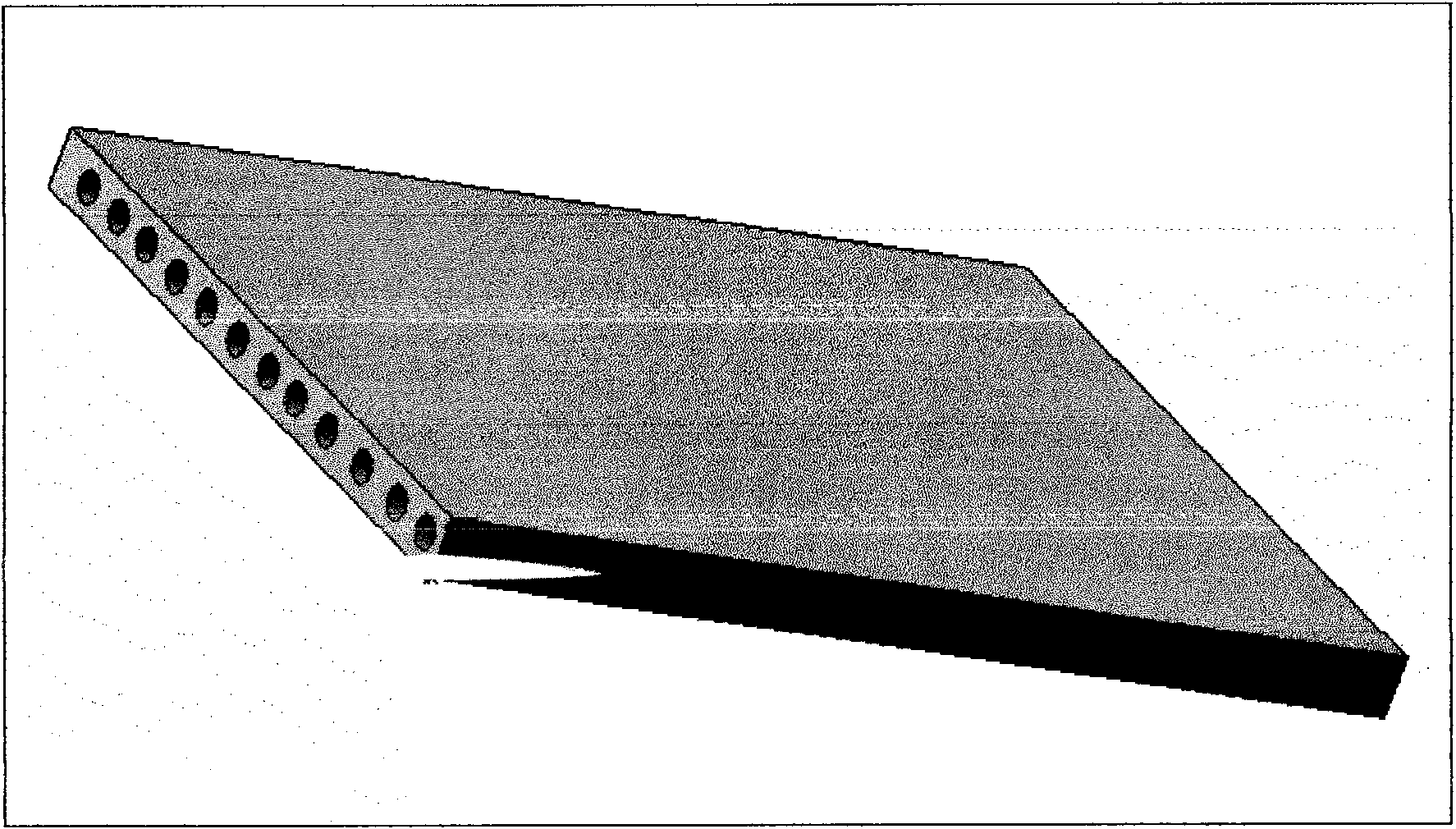

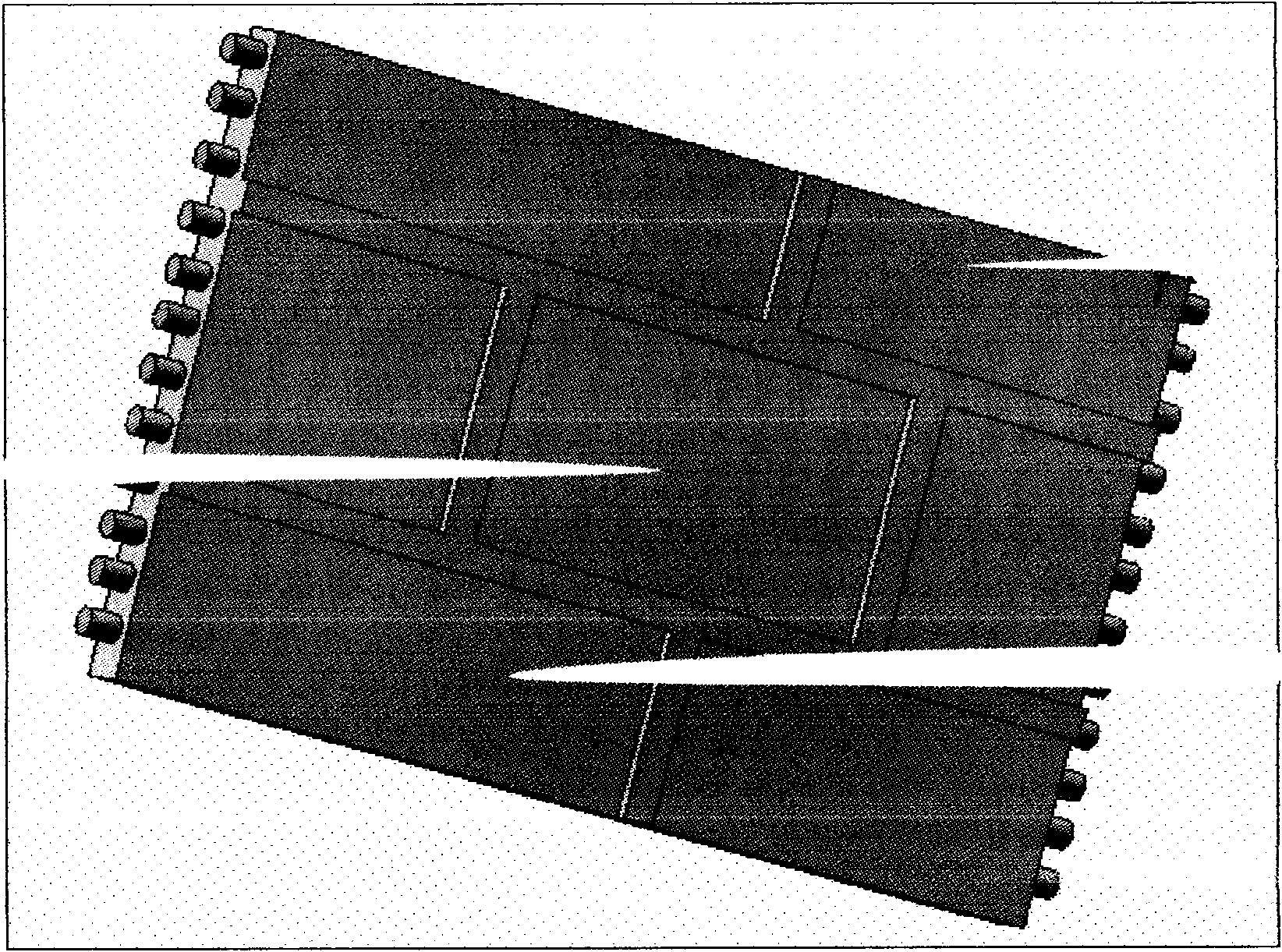

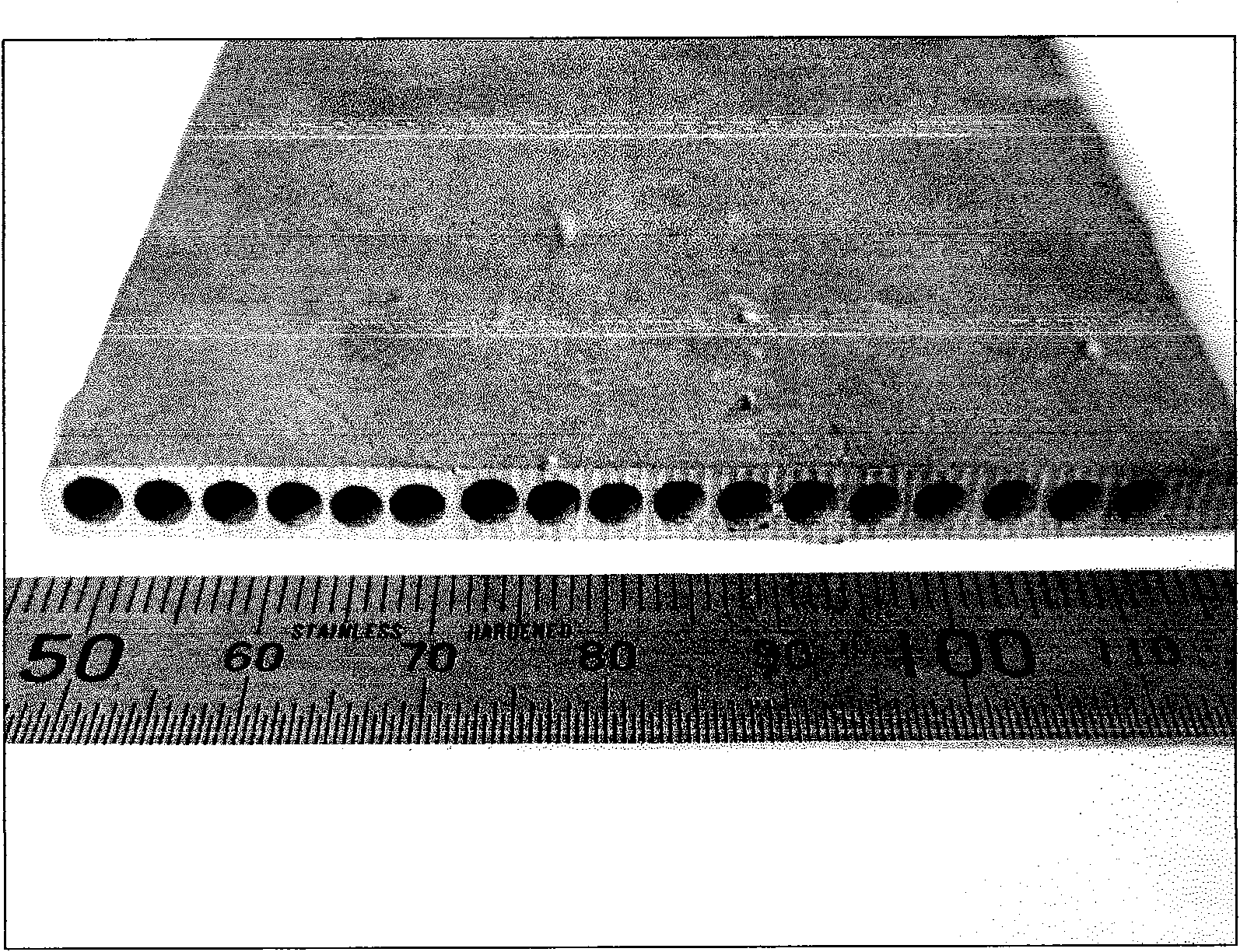

[0018] First select a high-purity quartz tube with a diameter of 3 mm, place the quartz tube in a mold, and prepare a wax model with a length of 200 mm, a width of 100 mm, and a height of 5 mm. The wall thickness of the wax model is 1 mm. The distance between the outer walls of the tube is 1 mm. One end of the quartz tube is a fixed end, and the other end is a free end. Platinum wires are used for positioning. Coating the wax model, the specific coating process is as follows: use 320 mesh corundum powder for the surface coating, silica sol as the binder, the powder-liquid ratio is 2:1, the air temperature is 25°C, the relative humidity is 50%, the first layer The drying time after the surface coating is 4 hours, the second layer of surface coating is 320 mesh corundum paint, the sanding material is 80 mesh fused corundum, the drying time is 8 hours, and the third layer is 200 mesh corundum paint , the sanding material is 60 mesh fused corundum powder, the drying time is 8 hou...

Embodiment 2

[0020] First select a high-purity quartz tube with a diameter of 3 mm, place the quartz tube in a mold, and prepare a wax model with a length of 200 mm, a width of 100 mm, and a height of 5 mm. The wall thickness of the wax model is 1 mm. The distance between the outer walls of the tube is 1 mm. One end of the quartz tube is a fixed end, and the other end is a free end. Platinum wire is used for positioning. Coating the wax model, the specific coating process is as follows: the coating is made of 320 mesh corundum powder, the binder is silica sol, the powder-to-liquid ratio is 2:1, the air temperature is 25°C, and the relative humidity is 50%. The drying time after the surface coating is 4 hours, the second layer of paint is 320 mesh corundum paint, the sanding material is 80 mesh zircon powder, the drying time is 8 hours, the third layer is 200 mesh corundum paint, and the sanding material is 60 mesh zircon powder, drying time is 8 hours, the fourth to sixth layers of paint ...

Embodiment 3

[0022] First select a silica ceramic core with a core diameter of 3 mm and a length of 215 mm, place the core in a mold, and prepare a wax model with a length of 200 mm, a width of 100 mm, and a height of 5 mm. The wall thickness is 1 mm, the distance between the outer walls of the core is 1 mm, one end of the core is a fixed end, the length is 10 mm, the other end is a free end, and the length is 5 mm, the specific value of the gap between the free end in the radial and axial directions is: radial The diameter is 50 microns, the axial length is 2 mm, and the ceramic cores are positioned with tungsten-rhenium wires. After the wax model is prepared, the wax model is coated. The specific coating process is as follows: 320 mesh corundum powder is used for the surface coating, the binder is silica sol, the powder-liquid ratio is 2:1, the air temperature is 20 °C, and the relative humidity is 60%, the drying time of the first layer of surface coating is 4 hours, the second layer of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com