Technology for preparing ethylene and propylene by catalytically cracking byproduct C4 material in coal to olefine

A technology for catalytic cracking and coal-to-olefins, applied in physical/chemical process catalysts, hydrocarbon cracking to hydrocarbons, molecular sieve catalysts, etc. Economy and operability, the effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

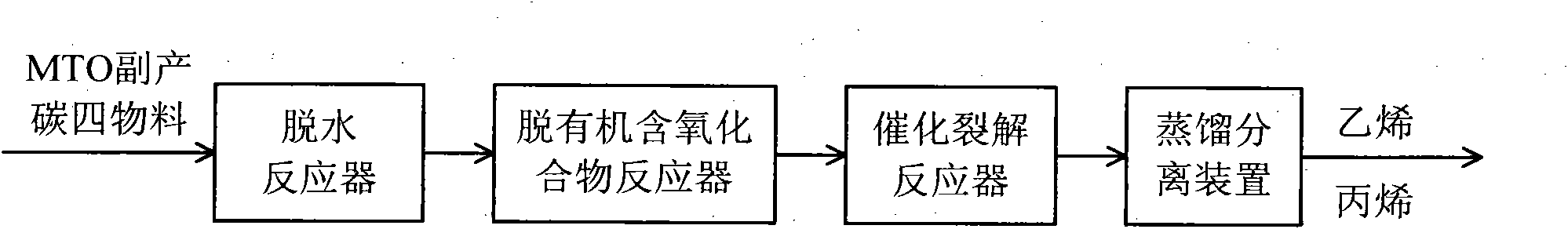

[0036] The technology of embodiment 1 MTO by-product C4 material catalytic cracking to produce ethylene and propylene

[0037] This embodiment provides a process for the production of ethylene and propylene by catalytic cracking of MTO by-product carbon four materials, and its process flow is as follows figure 1 shown.

[0038] The flow rate of the C4 material used in this embodiment is 10 tons / h, the n-butene concentration in the C4 material is 90%, the water content is about 300ppm, and the content of organic oxygen-containing compounds such as methanol and dimethyl ether is about is 800ppm, and the remainder is butane.

[0039]The technique provided in this embodiment comprises the following steps:

[0040] Step a: Make the MTO by-product carbon four material pass through a 20m 3 In the dehydration reactor of 3A molecular sieve, the water content in the C4 material drops from 300ppm to 50ppm, and the material A is obtained;

[0041] Step b: Make material A enter the rea...

Embodiment 2

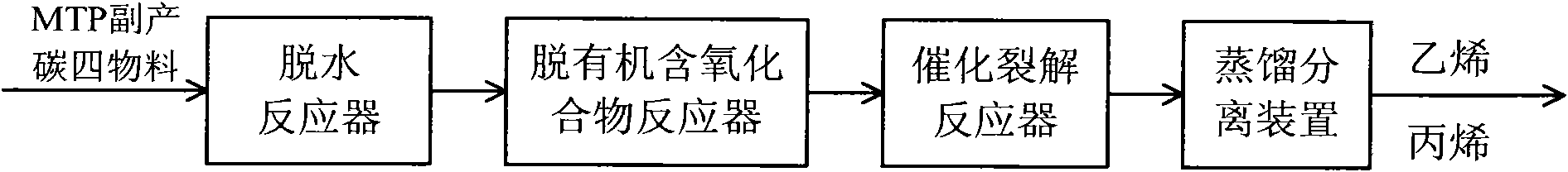

[0045] The technology of embodiment 2 MTP by-product C4 material catalytic cracking to produce ethylene and propylene

[0046] This embodiment provides a process for the production of ethylene and propylene by catalytic cracking of MTP by-product C4 material, and its process flow is as follows figure 2 shown.

[0047] The flow rate of the C4 material used in this embodiment is 5 tons / h. After the MTP by-product C4 material is subjected to conventional distillation or extractive distillation, the concentration of n-butene in it is 95%, and the water content is about 150ppm. The content of organic oxygen-containing compounds such as methyl ether is about 500ppm, and the rest is butane.

[0048] The technique provided in this embodiment comprises the following steps:

[0049] Step a: make the MTP carbon four material pass through the 8m 3 13X type molecular sieve dehydration reactor, the water content in the material is reduced from 150ppm to 50ppm, and the material A is obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com