Method for synthesizing acetoacetate ester compound

A technology of acetoacetate and diacetoacetate, which is applied in the field of polymer chemical materials, can solve the problems of poor thermal stability of tert-butyl acetoacetate, achieve shortened reaction time, high reaction conversion rate, and mild synthesis method Effect

Inactive Publication Date: 2011-01-12

SUN YAT SEN UNIV

View PDF3 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Using tert-butyl acetoacetate to pyrolyze and synthesize acetoacetate compounds with more complex molecular structures is a new technology method with more reports today. The thermal stability of tert-butyl acetoacetate is relatively poor. By heating tert-butyl acetoacetate at high temperature, Decompose and remove tert-butanol to form ketene intermediate, and react with other alcohol materials that are relatively difficult to volatilize immediately to obtain acetoacetate. This method requires continuous high temperature conditions and the reaction time lasts for several hours.

Due to these deficiencies, these methods have relatively large limitations in the application of multifunctional acetoacetate compounds.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

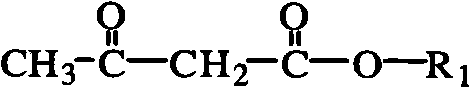

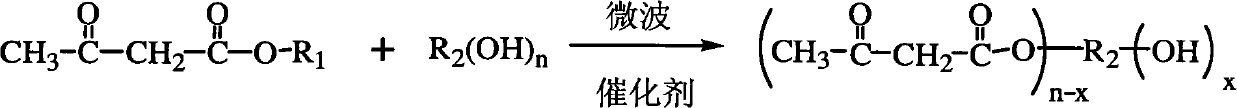

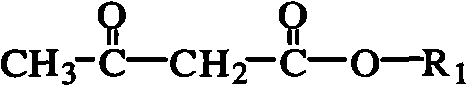

The invention belongs to the field of polymer materials, relating to a method for synthesizing acetoacetate ester modified polymer. The method comprises the following steps: taking polymer containing hydroxyl and micromolecule acetoacetate ester as raw materials, and performing reaction under the condition of microwave irradiation; and the equation is shown in the specification, wherein R2(OH)n is polymer containing multi-hydroxy. The invention synthesizes the polymer of which side chains or chain ends have a plurality of acetoacetate ester groups by the process of catalytic ester exchange. The synthetic method has the advantages of high efficiency, mild synthetic method and high safety. In addition, in the method, the catalyst can be added, thereby improving synthetic efficiency; the synthetic rate of the method is greatly improved compared with the prior art; and the reaction time is shortened to 2-30min.

Description

technical field The invention belongs to the field of macromolecular chemical materials, in particular to a method for quickly and easily synthesizing polyacetoacetate-based polymers / acetoacetate-based macromolecular compounds. Background technique Coatings, inks, adhesives, polymer composites and other industrial fields generally involve the cross-linking and polymerization of polymer materials to improve the mechanical properties and environmental tolerance of the materials, so that the materials have a certain protective effect and service life. Traditional crosslinking polymerization methods mainly include free radical polymerization crosslinking, isocyanate / polyol crosslinking, etc. Compounds based on the beta-dicarbonyl structure are due to the methylene (-CO-CH 2 -CO-) has considerable chemical reactivity, and can perform Michael addition with carbon-carbon double bonds of alpha, beta ring saturated structures such as acrylate under appropriate catalytic conditions, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08G65/48C08B3/08C08G63/91C08J3/28

Inventor 杨建文庞来兴曾兆华

Owner SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com