Two-phase shock wave swing link movable-teeth compound transmission speed reducer

A movable tooth compound, shock wave technology, applied in the direction of gear transmission, transmission, belt/chain/gear, etc., can solve the problem of easy gluing failure of movable tooth transmission, reduced heat generation of movable tooth transmission, and increased transmission ratio of reducer. It can achieve the effect of compact structure, reduce heat generation and temperature rise, and reduce input speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

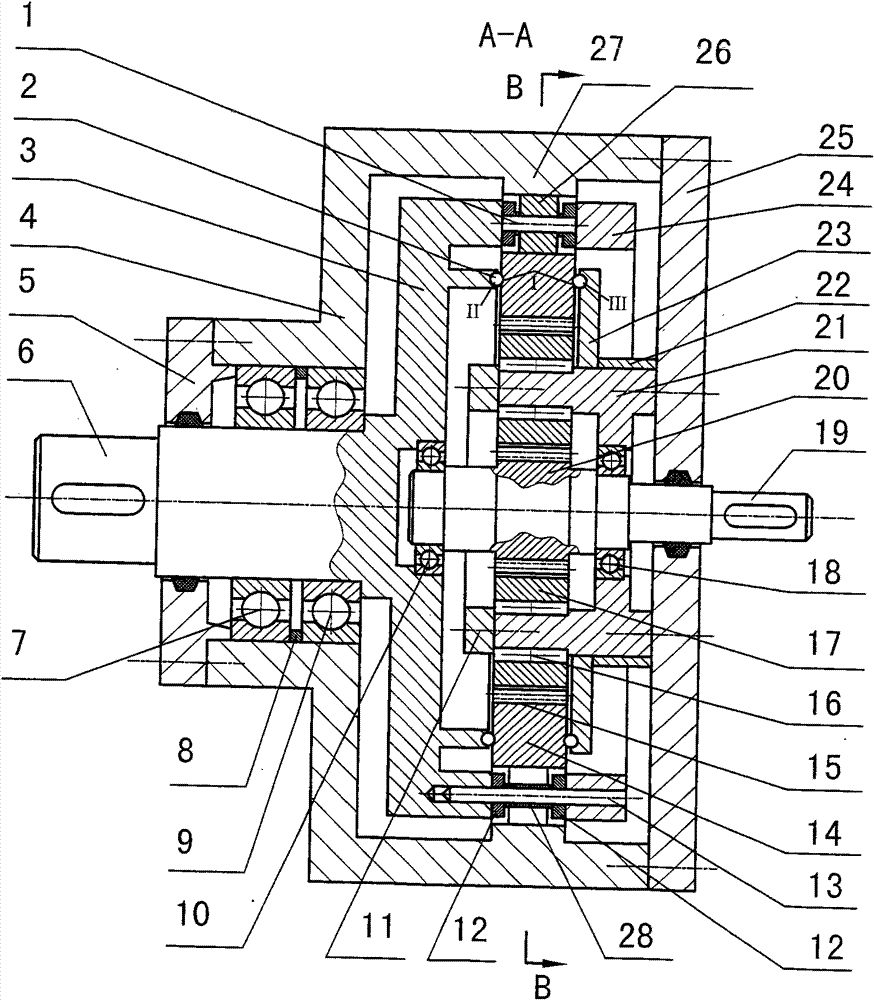

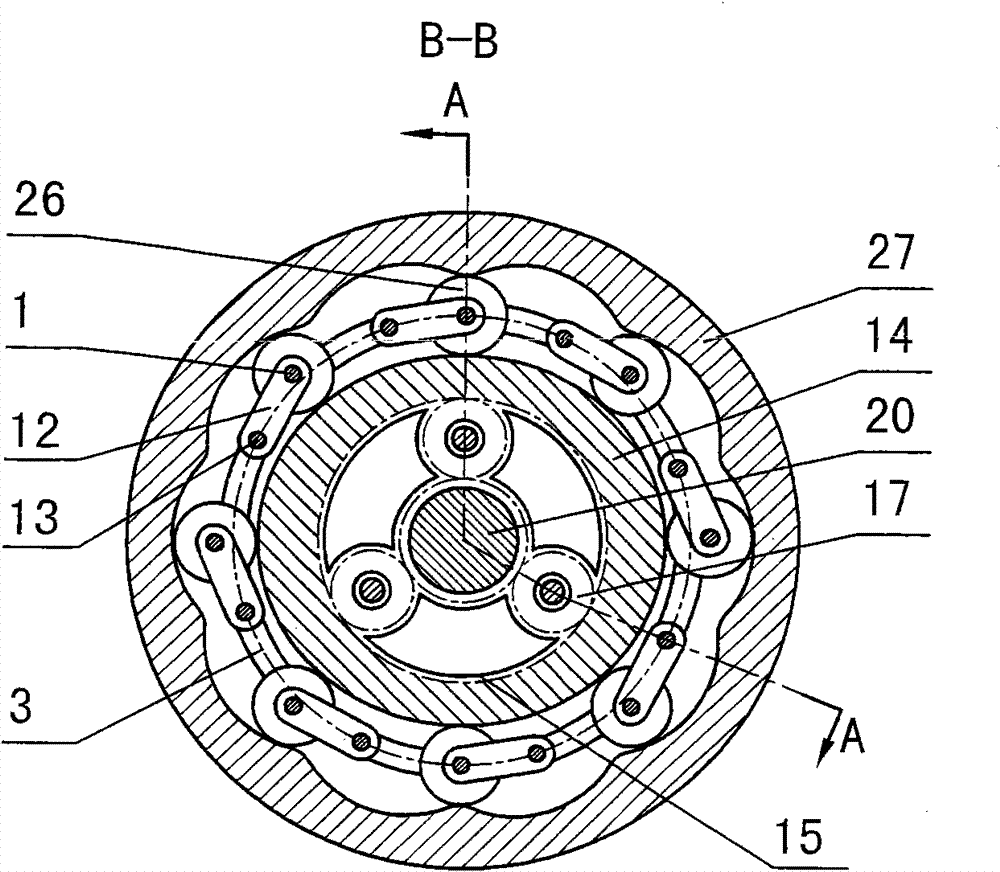

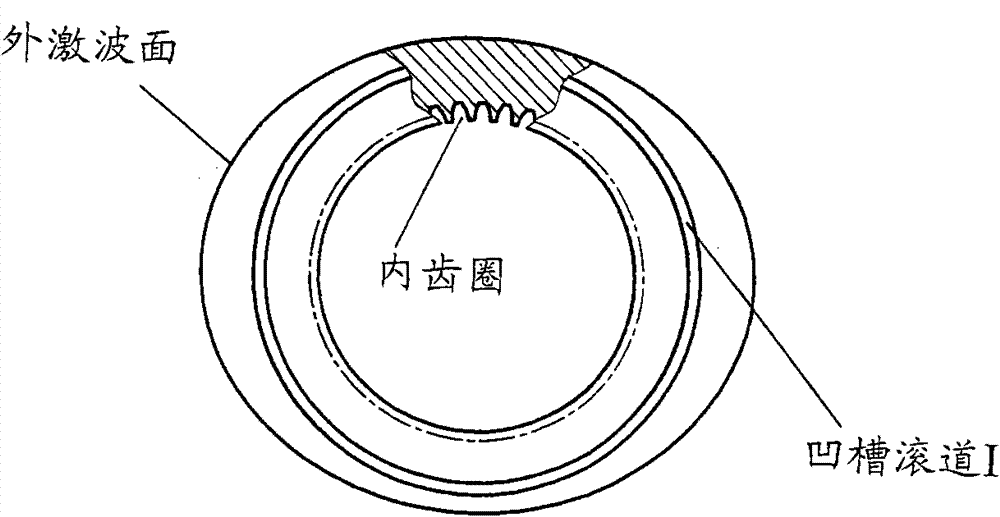

[0040] in figure 1 with figure 2 Among them, the dual-phase shock swing rod movable tooth compound transmission reducer is composed of movable tooth pin shaft (1), thrust ball bearing (2) (two-phase shock device axial positioning device), movable tooth frame (3), box body (4), bearing end cover (5), output shaft (6), rolling bearing (7), gasket (8), rolling bearing (9), (10), needle limit disk (11), swing lever (12) ), swing rod pin (13), dual-phase shock (14), internal gear (15), needle bearing (16), pinion (17), rolling bearing (18), input shaft (19), Input gear (20), pinion bracket (21), sleeve (22), thrust plate (23), floating plate (24), box cover (25), movable teeth (26), center wheel (27) and pendulum Rod pin shaft sleeve (28) and other components. A number of swing rod pins (13) (the number of swing rod pins is equal to the number of movable teeth) are evenly distributed in the circumferential direction, one end is fixed in the movable gear frame (3), the other end is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com