Method for detecting large-caliber aspheric optical element by utilizing three-coordinate measuring machine

A three-coordinate measuring machine and spherical optics technology, which is applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve problems that affect the detection accuracy of optical components, long cycles, errors, etc., and achieve the effect of improving the accuracy of three-coordinate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1, detect caliber by the method of the present invention The process of aspheric mirror:

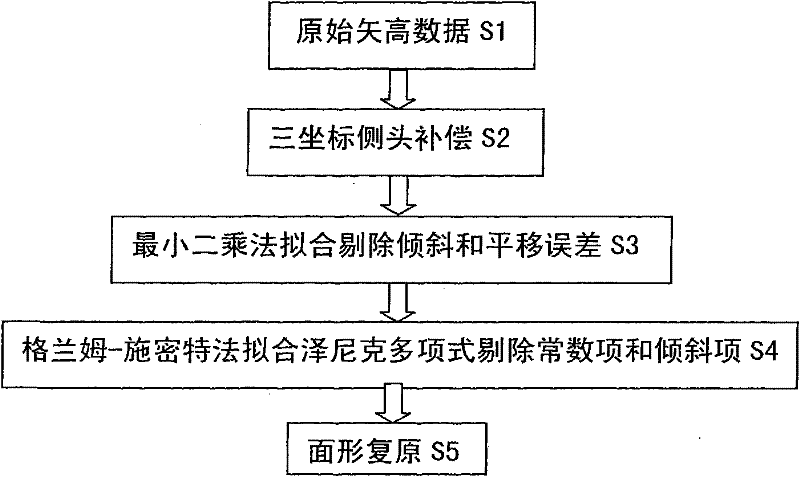

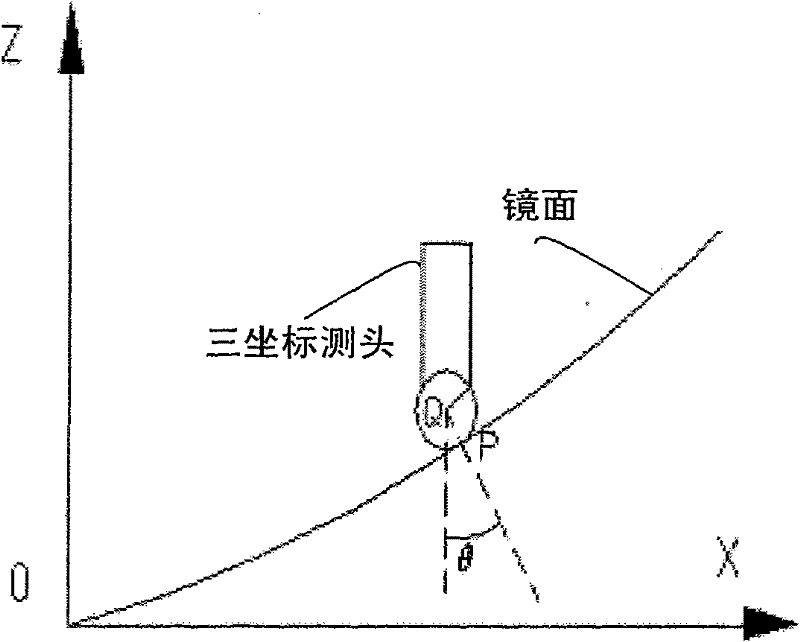

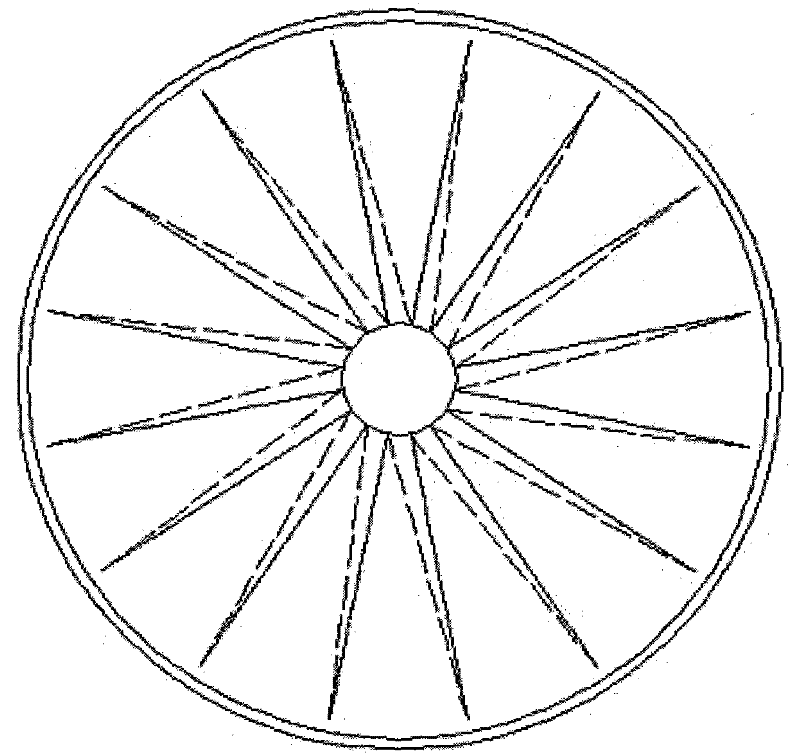

[0025] (1) if figure 1 The flow chart of data processing for detecting large-aperture aspheric optical elements with a three-coordinate measuring machine is shown, according to image 3 The measurement route shown measures 16×45 measurement points on the full aperture of the aspheric mirror, and obtains Figure 4 The surface height loss diagram shown, Figure 4 The middle abscissa is the diameter of the aspheric mirror, and the vertical coordinate is the height loss data of the aspheric mirror along the diameter direction. It can be seen that a total of 8 diameter lines and 16 radius lines have been measured, so there are a total of 16×45 measurement points in the full aperture, but this The detection graph is not intuitive, use the measurement point to draw the surface plan, such as Figure 5 It shows that the horizontal and vertical coordinates are the coordinate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com