Near infrared spectrum and microscopic bacterial plaque area data fusion-based pork freshness non-destructive testing technology

An area and data technology, applied in the field of meat quality inspection system, can solve the problems of expensive equipment, complicated process, long detection time, etc., and achieve the effect of avoiding data deviation, accurate detection, simple detection structure and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

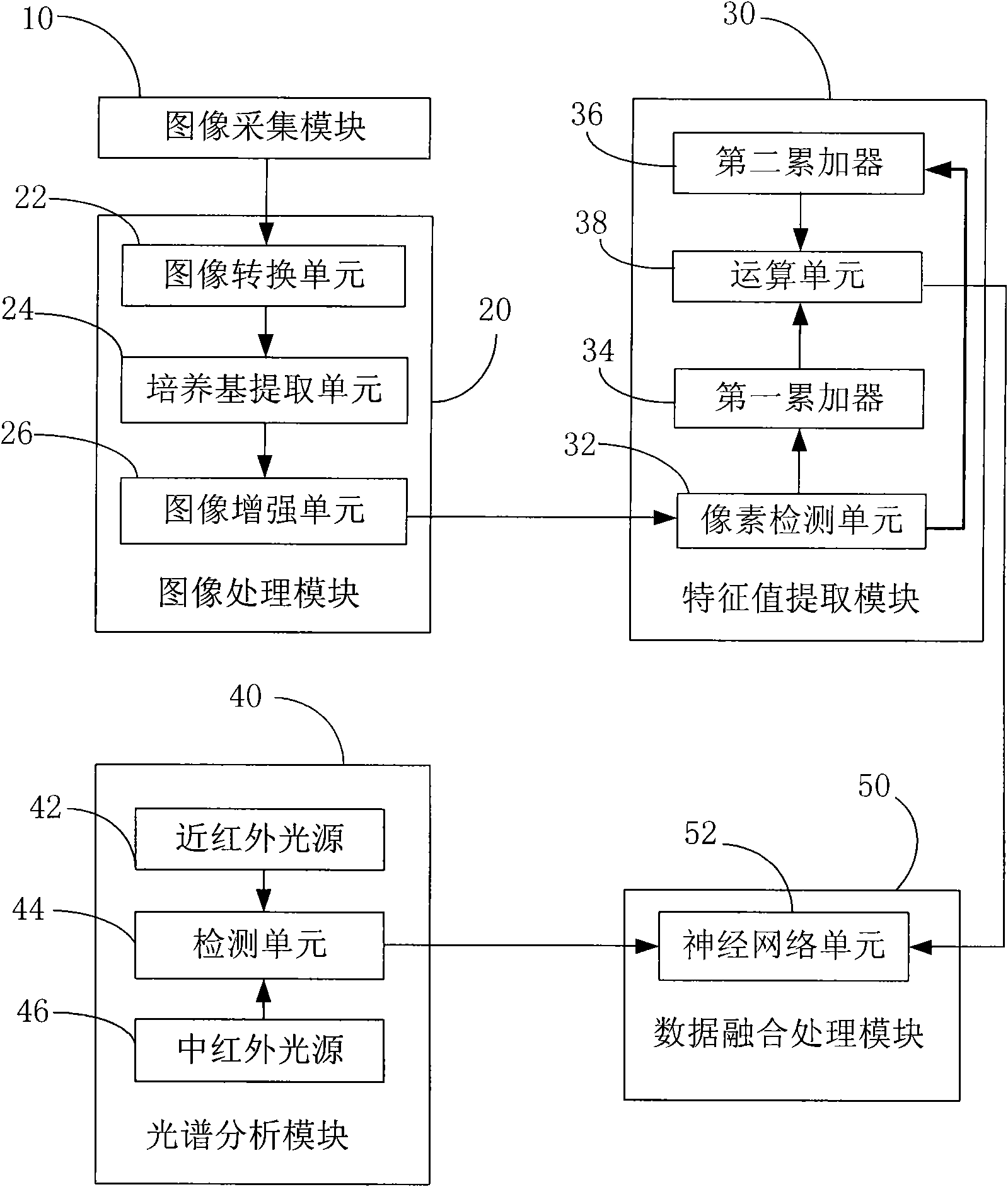

[0018] Please refer to Figure 1 to Figure 3 A preferred embodiment of the meat quality detection system 1 of the present invention includes an image acquisition module 10 , an image processing module 20 , a feature value extraction module 30 , a spectral analysis module 40 , and a data fusion processing module 50 . The image processing module 20 includes an image conversion unit 22 , a medium extraction unit 24 and an image enhancement unit 26 .

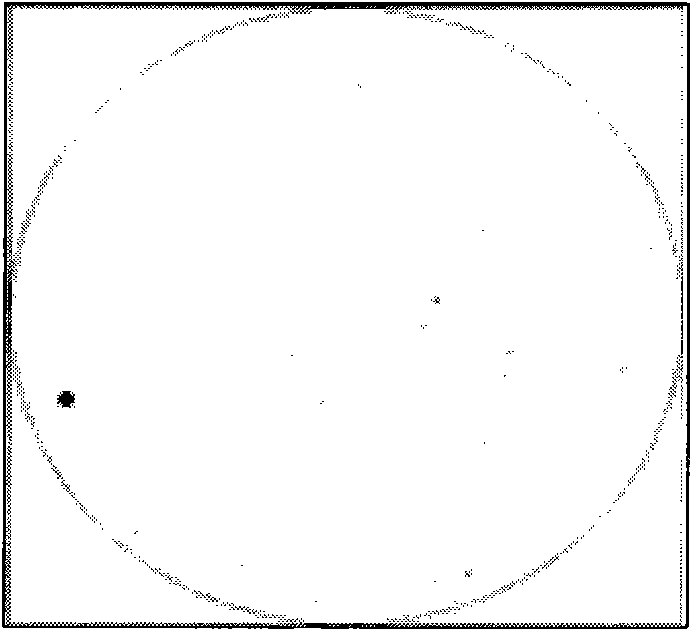

[0019] The image acquisition module 10 includes a CCD (Charge-coupled Device, charge-coupled device) microscope, which is used to collect images of adipose tissue in the meat sample to be tested, and the adipose tissue contains quality indicators characterizing the meat to be tested, That is, bacterial plaques of bacteria growing on the meat to be tested. During the specific operation, a sterilized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com