Sliding bearing of anode disc for high rotational speed

A technology of sliding bearings and rotating anodes, which is applied in the direction of sliding contact bearings, rotating bearings, bearings, etc., can solve the problem that the power of driving equipment can no longer be accepted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

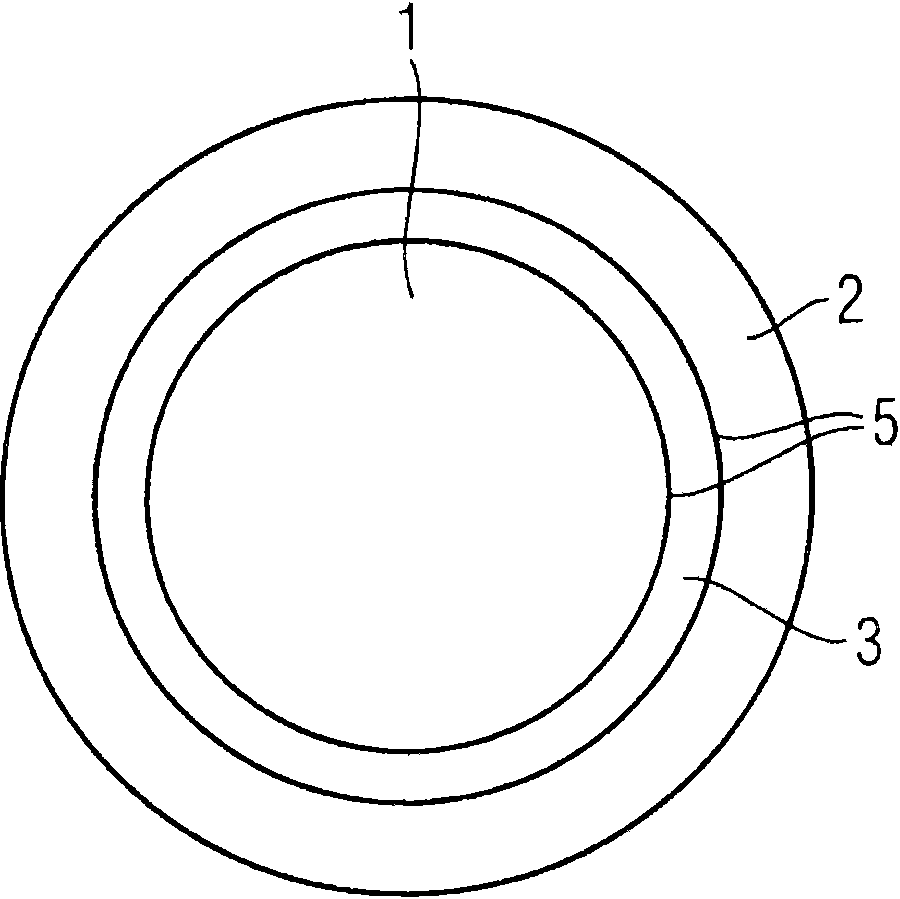

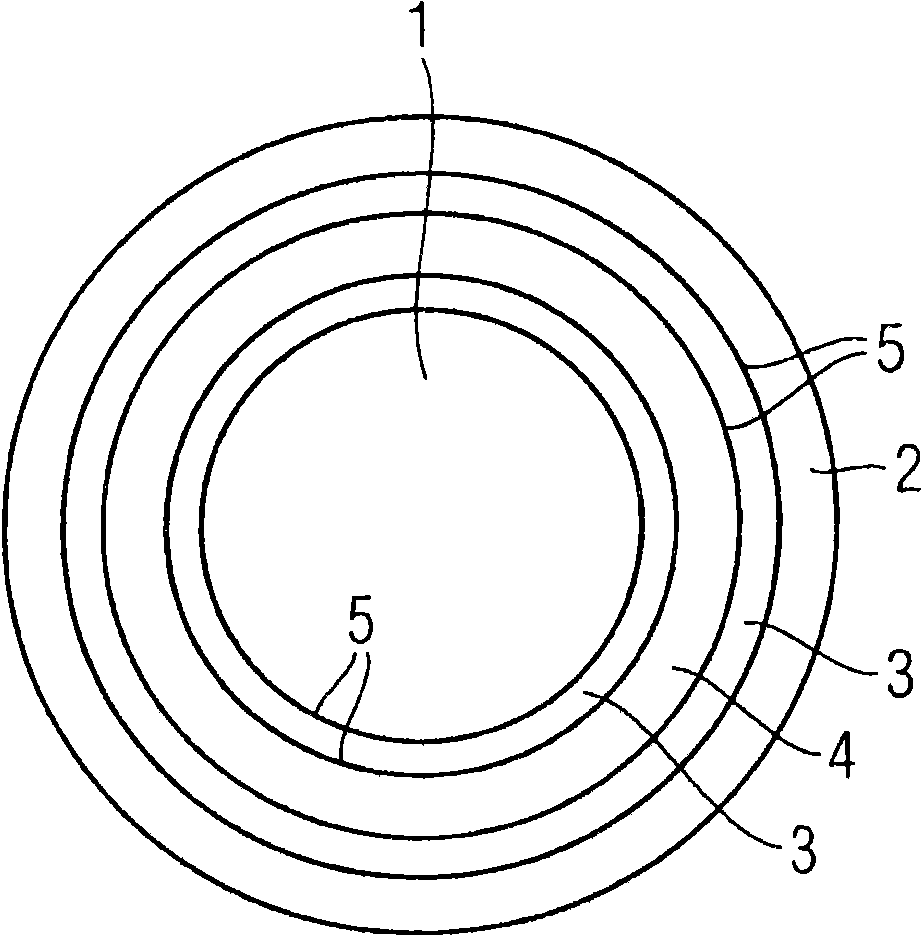

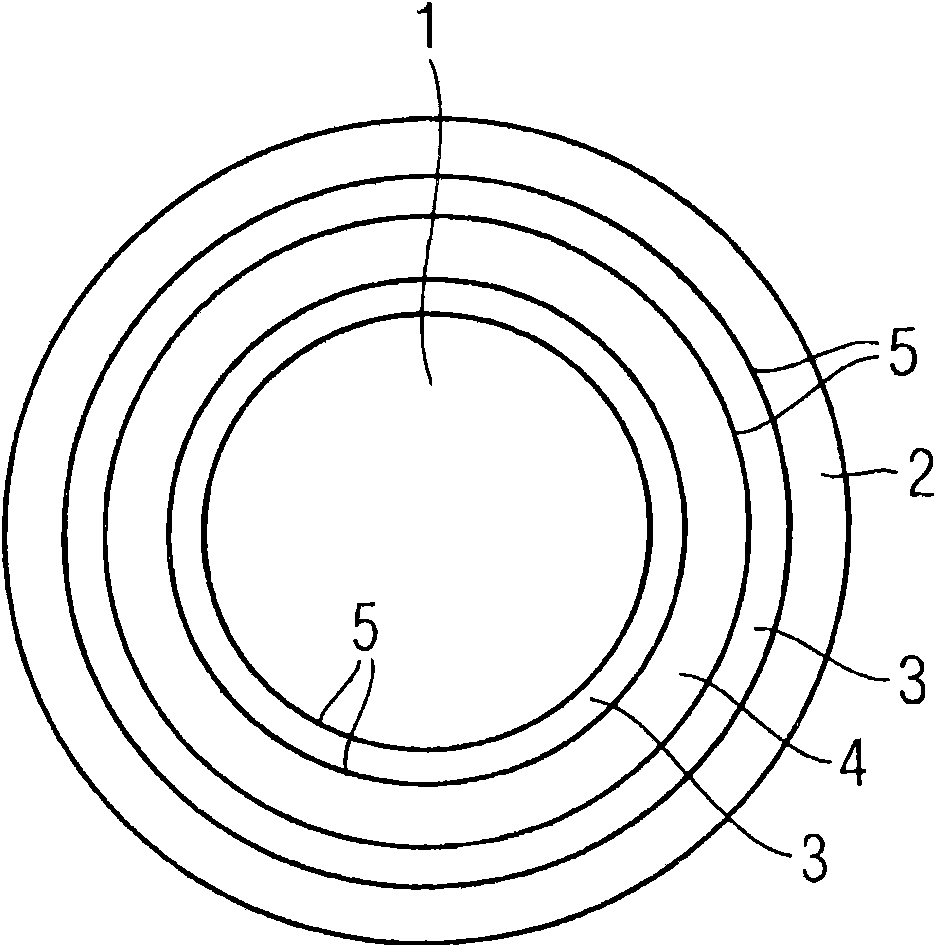

[0014] figure 1 A prior art slide bearing for an anode disk is shown in cross section. The slide bearing is formed by a bearing shell 2 and an inner shaft 1 mounted in the bearing shell 2 . The inner shaft 1 forms, for example, a stationary bearing part, while the bearing shell 2 forms a movable bearing part. An anode disc is fixed on the rotatable bearing bush 2 . The inner shaft 1 is fixedly connected to an x-ray tube housing and can be cooled from the inside.

[0015] Between two concentrically arranged bearing parts 1, 2 there is a bearing gap 3 formed by the bearing bearing surfaces 5 of the two bearing parts 1, 2, for example with a gap width of about 20 microns, which is filled with A liquid metal such as gallium-indium-tin. The rotational speed-dependent wear in the bearing gap 3 limits the rotational frequency for the anode disk to below 200 Hz. A major advantage of plain bearings is the large-area contact between the bearing shell 2 and the inner shaft 1 by mean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com