Manufacturing method of lithium-ion battery pack used for electric automobile

A technology for a lithium-ion battery pack and a manufacturing method, which is applied in the field of automobiles, can solve problems such as hidden dangers of safety, many batteries in series and parallel, unfavorable for mass production, etc., and achieves the effect of assembly safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be specifically described below in conjunction with the accompanying drawings.

[0024] First, perform 5 to 10 charge and discharge cycles on the lithium iron phosphate single battery 1 that needs to be assembled according to the same charge and discharge parameters, and then fully charge the single battery 1 and store it at 50°C to 80°C for 5 to 15 days. Aging treatment, the single battery 1 to be matched is selected according to the capacity change of a single battery within 5 to 10 charge-discharge cycles ≤ 1%, the capacity difference between individual batteries ≤ 2%, and the internal resistance difference of the battery after high-temperature aging is less than 3mΩ , the voltage difference is less than 3mV.

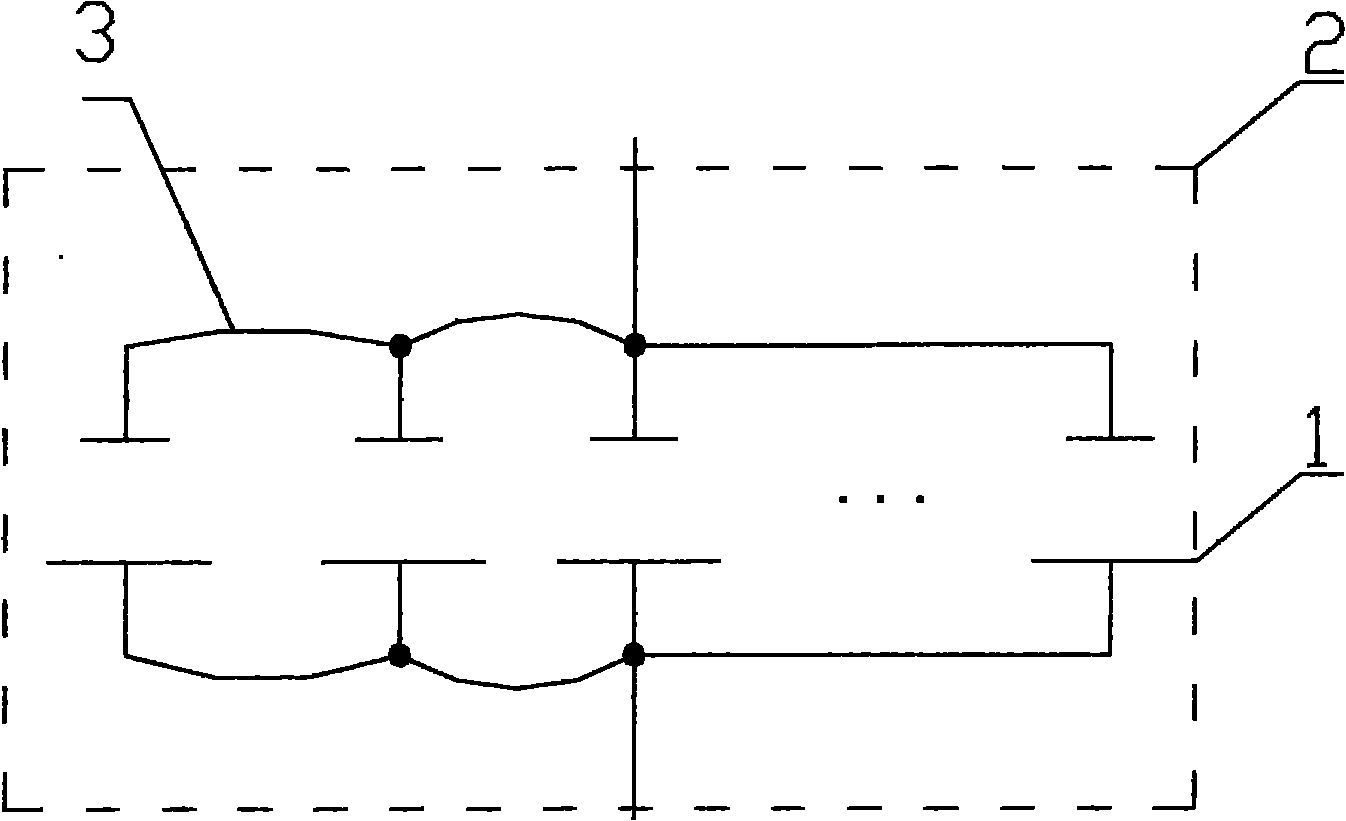

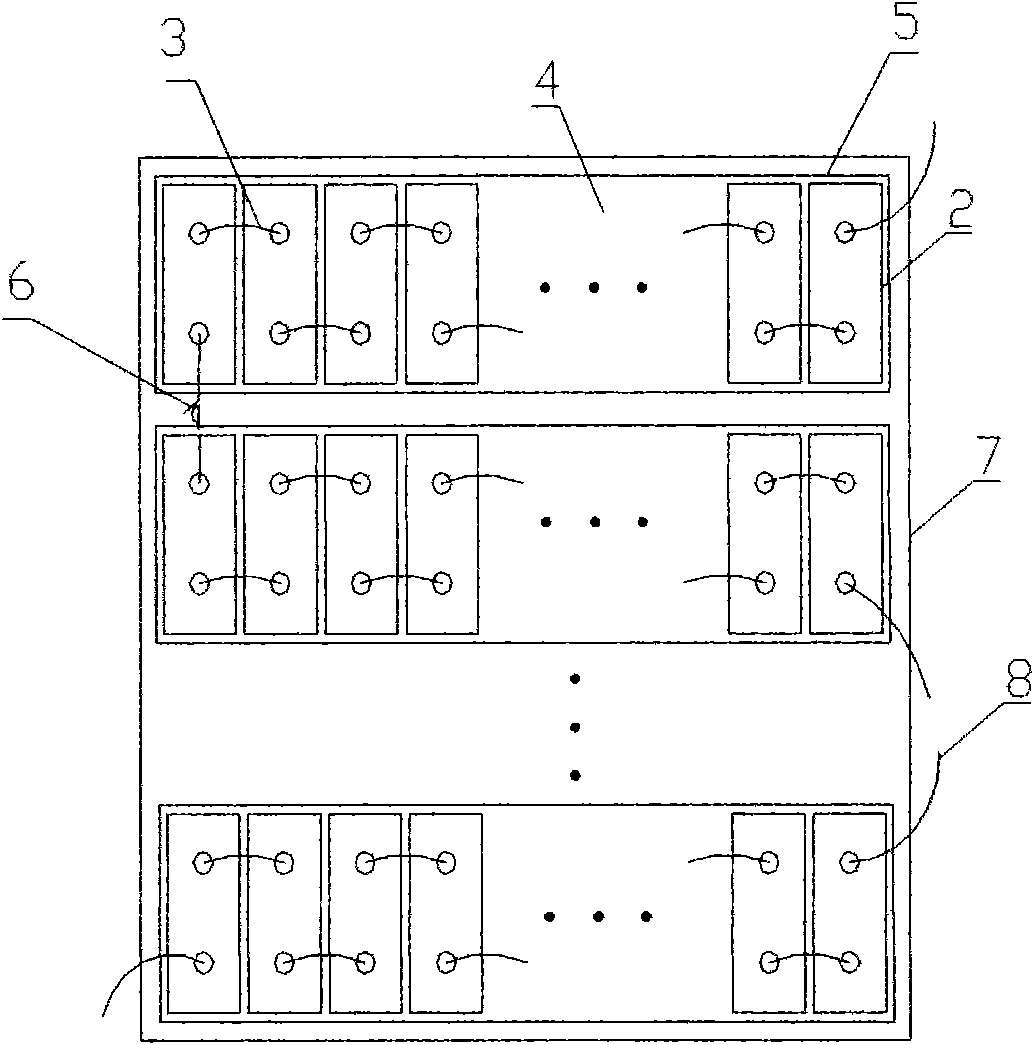

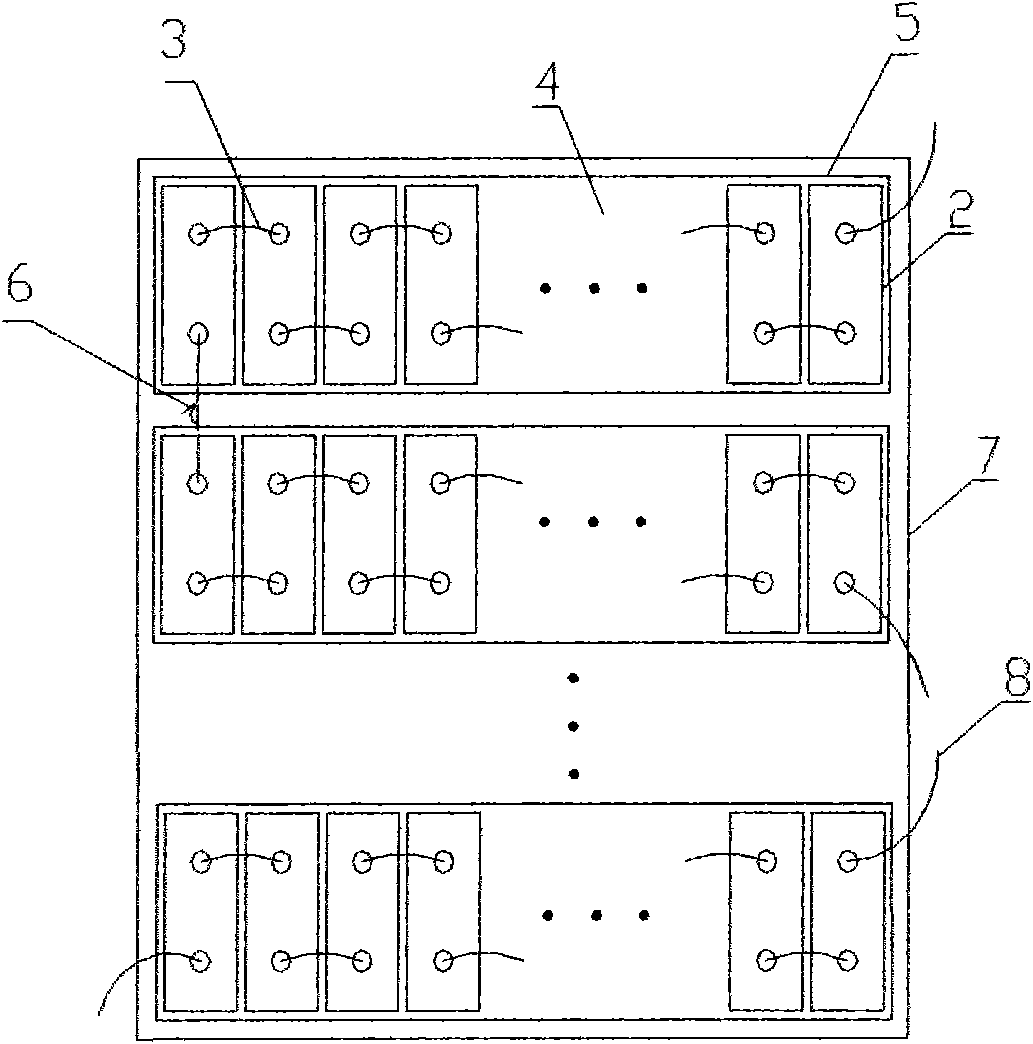

[0025] refer to figure 1 A plurality of single batteries 1 are connected in parallel to form a battery unit 2 by means of arc-shaped copper and nickel-plated copper connection plates 3 by means of spot welding or stop nut connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com