New compound semiconductor and producing method thereof, and solar cell and thermoelectric conversion element using the same

A technology of solar cells and thermoelectric conversion, applied in the direction of oxide conductors, sulfide conductors, semiconductor devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

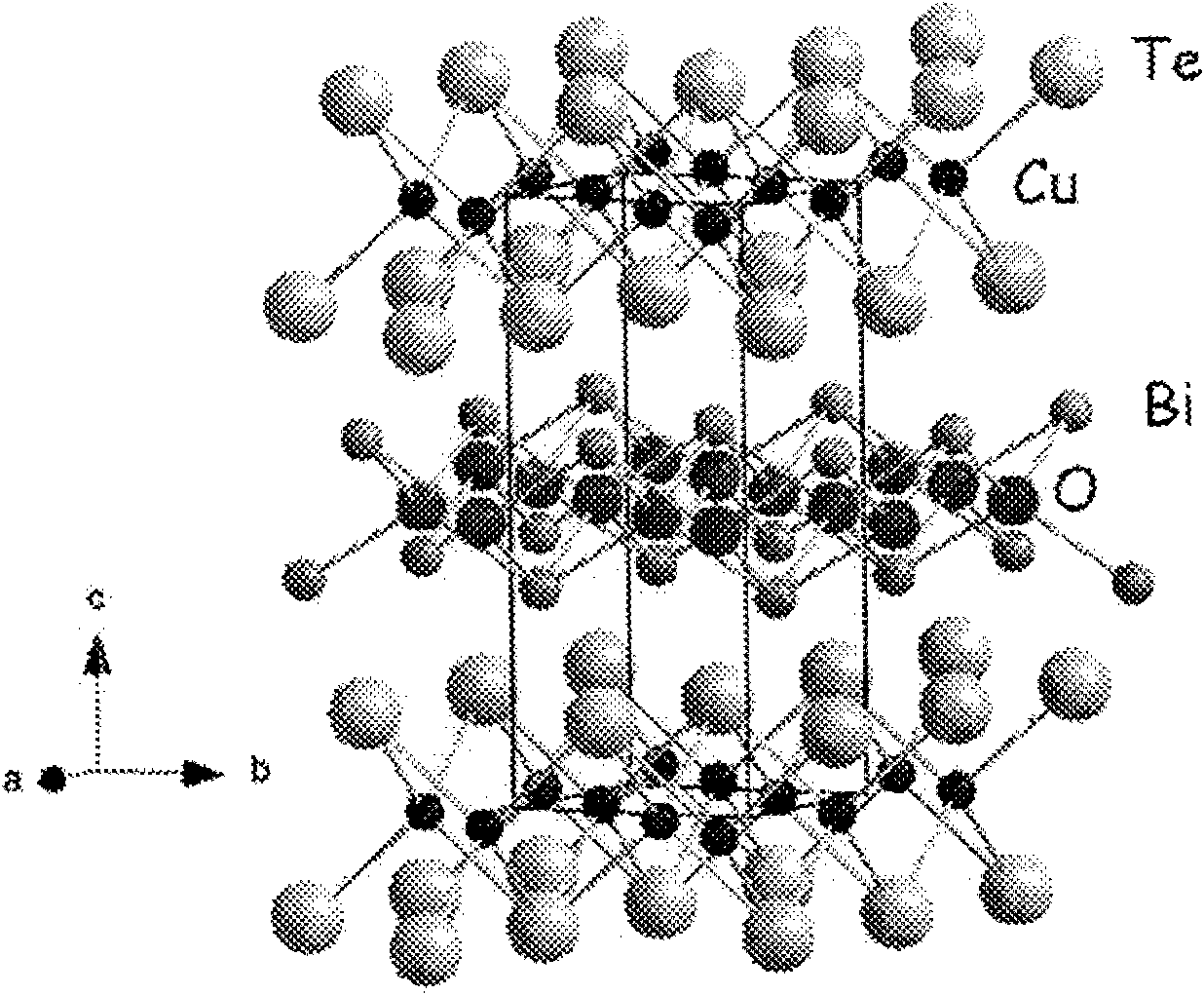

[0068] BiCuOTe

[0069] To prepare BiCuOTe, 1.1198 g of Bi 2 o 3 (Aldrich, 99.9%, 100 mesh), 0.5022g of Bi (Aldrich, 99.99%, <10m), 0.4581g of Cu (Aldrich, 99.7%, 3m) and 0.9199g of Te (Aldrich, 99.99%, about 100 mesh ), and then heated in a vacuum quartz tube at 510 °C for 15 hours to obtain BiCuOTe powder.

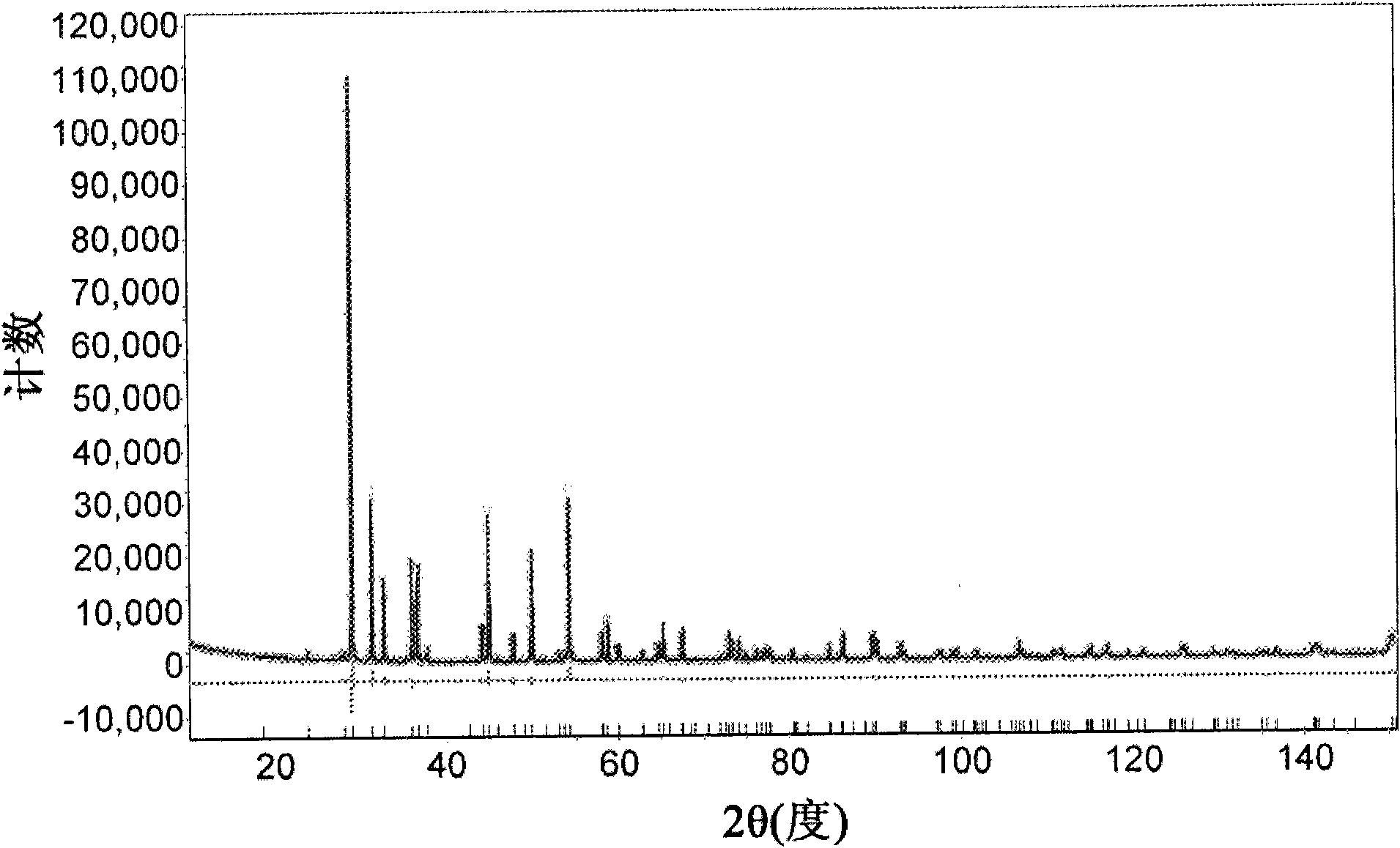

[0070] Cu X-ray tube ( 50kV, 40mA) to measure powder X-ray diffraction (XRD) data. The step size is 0.02 degrees.

[0071] The TOPAS program (R.W. Cheary, A. Coelho, J. Appl. Crystallogr. 25 (1992) 109-121; Bruker AXS, TOPAS 3, Karlsruhe, Germany (2000)) was used to determine the crystal structure of the obtained material. The analysis results are shown in Table 1 and figure 2 middle.

[0072] 【Table 1】

[0073] atom

Location

x

y

z

share

Beq

Bi

2c

0.25

0.25

0.37257(5)

1

0.56(1)

Cu

2a

0.75

0.25

0

1

0.98(3)

O

2b

0.75

0.25

0....

Embodiment 2

[0078] BiCu 0.9 OTe

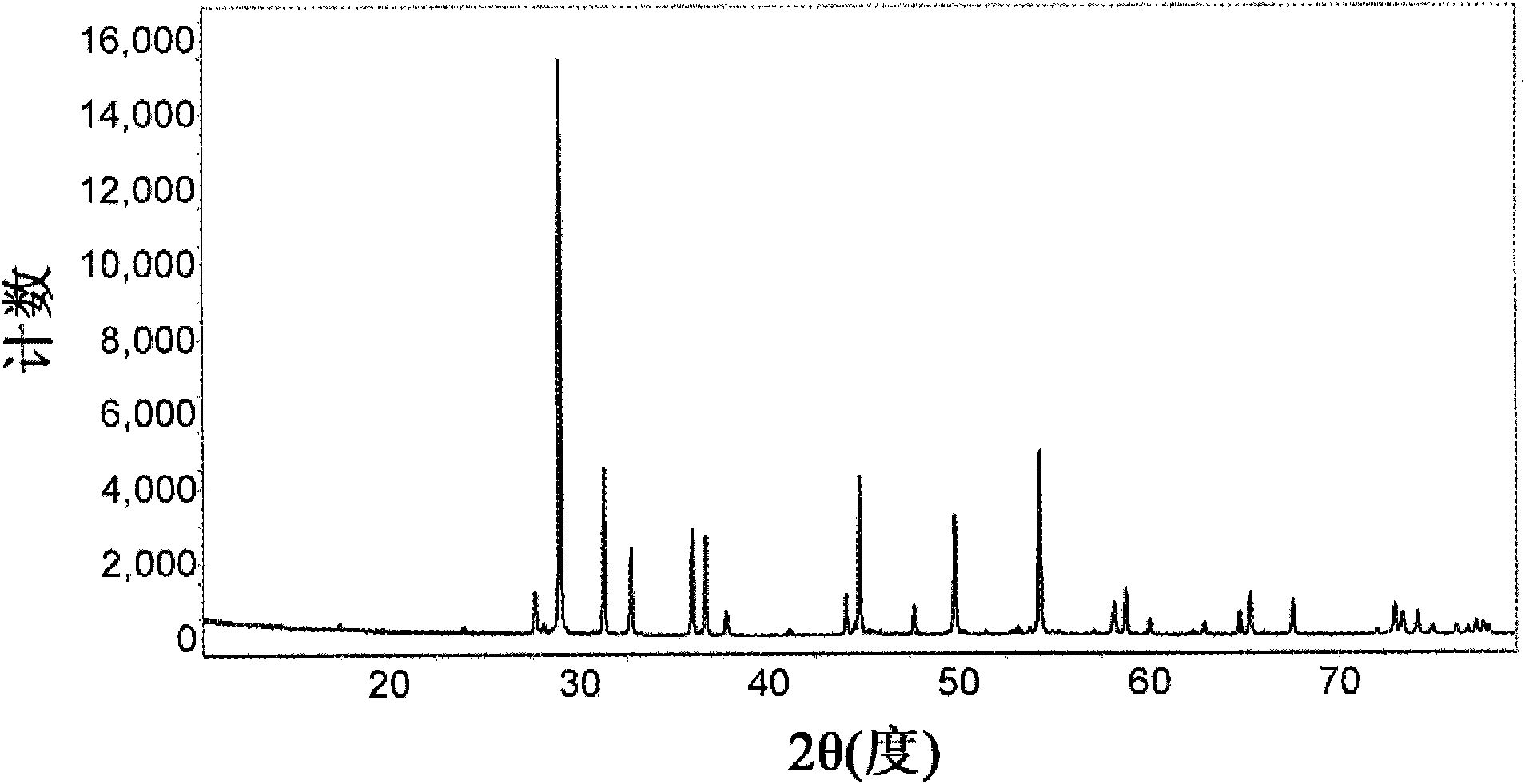

[0079] In order to prepare BiCu 0.9 OTe, 1.1371 g of Bi was thoroughly mixed by using an agate mortar 2 o 3 (Aldrich, 99.9%, 100 mesh), 0.51g of Bi (Aldrich, 99.99%, 0.9 OTe powder.

[0080] X-ray diffraction analysis of this sample was carried out in the same manner as in Example 1. like image 3 As shown, the material obtained in Example 2 was identified as BiCu 0.9 TeO.

Embodiment 3

[0082] Bi 0.98 Pb 0.02 CuOTe

[0083] To prepare Bi 0.98 Pb 0.02 CuOTe, by thoroughly mixing 2.5356 g of Bi using an agate mortar 2 o 3 (Aldrich, 99.9%, 100 mesh), 1.1724g of Bi (Aldrich, 99.99%, 0.98 Pb 0.02 CuOTe powder.

[0084] Cu X-ray tube ( 50kV, 40mA) to measure powder X-ray diffraction (XRD) data. The step size is 0.02 degrees.

[0085] The TOPAS program (R.W. Cheary, A. Coelho, J. Appl. Crystallogr. 25 (1992) 109-121; Bruker AXS, TOPAS 3, Karlsruhe, Germany (2000)) was used to determine the crystal structure of the obtained material. The analysis results are shown in Table 2 and Figure 5 middle.

[0086] 【Table 2】

[0087] atom

Location

x

y

z

share

Beq

Bi

2c

0.25

0.25

0.37225(12)

0.98

0.59(4)

Pb

2c

0.25

0.25

0.37225(12)

0.02

0.59(4)

Cu

2a

0.75

0.25

0

1

1.29(10)

O

2b

0.75

0.25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com