Automatic modular anaerobic and aerobic fermentation device

A kind of aerobic fermentation and modular technology, applied in fertilization equipment, aerobic and anaerobic process treatment, chemical industry, etc., can solve the problems of inconvenient disassembly and installation, inability to change the construction scale, threats to the living environment, etc., and achieve cost reduction Small, prolonged heat supply time, efficient anaerobic fermentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

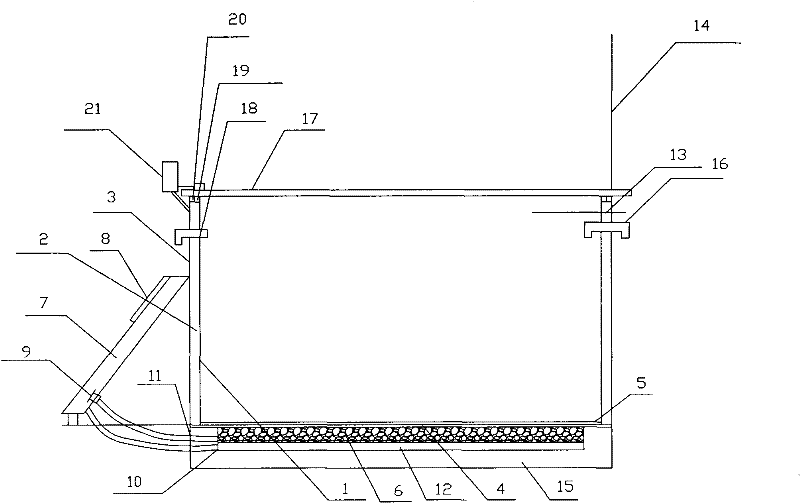

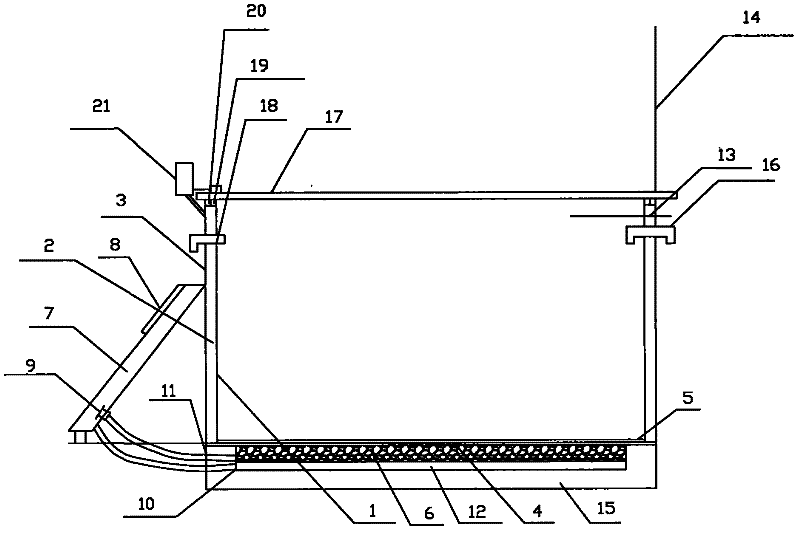

[0026] The schematic diagram of the strip pool-shaped self-powered modular anaerobic and aerobic fermentation device of the present invention is as follows figure 1 As shown, it includes an energy storage foundation tank 15, an above-ground fermentation tank body 1 spliced by formwork blocks, a solar collector 7, a photovoltaic power generation panel 8, and an axial flow fan 9, wherein the solar collector 7 is installed on a sunny On the one hand, the template block is engineering plastic or metal plate. The energy storage base tank 15 is equipped with a metal heat conduction plate 4 as the bottom plate of the above-ground fermentation tank body. The bottom of the energy storage base tank is provided with a hot air duct 12. 10 connectivity. A partition with an air outlet is arranged on the hot air duct, and a heat conduction medium 6 is arranged between the metal heat conducting plate and the partition with an air outlet, and the heat conduction medium is pebbles or coal ga...

Embodiment 2

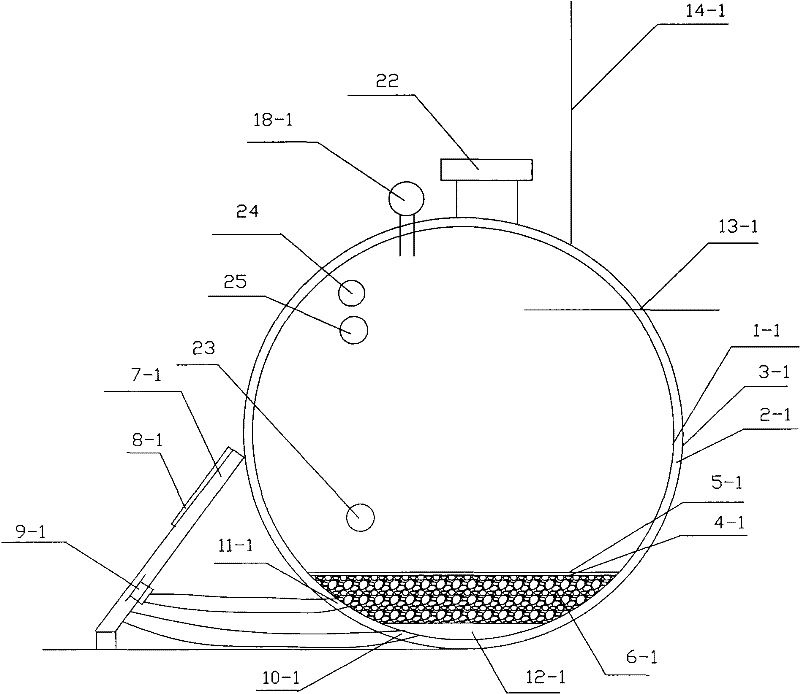

[0035] The schematic diagram of the round tank-shaped automatic power module type anaerobic and aerobic fermentation device of the present invention is as figure 2 As shown, it includes a round tank-shaped tank 1-1 spliced by formwork blocks, a solar collector 7-1, a photovoltaic power generation panel 8-1, and an axial flow fan 9-1. The splicing of two adjacent formwork blocks seal, the template block is engineering plastics or metal plate. The interior of the round pot-shaped tank body is divided into a fermentation room and an energy storage room by a metal heat conducting plate 4-1. An air inlet channel 12-1 is arranged in the energy storage room, and the hot air channel is corresponding to the energy storage room. The hot-blast air inlet 10-1 of the bottom of the round pot-shaped tank body at the position is communicated with. A partition with an air outlet is provided on the hot air duct, and a heat conduction medium 6-1 is provided between the metal heat conducting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com