Process for the recovery of oxidation catalyst using ion exchange resins

An exchange resin, cation exchange technology, applied in the direction of organic anion exchanger, organic cation exchanger, ion exchange, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

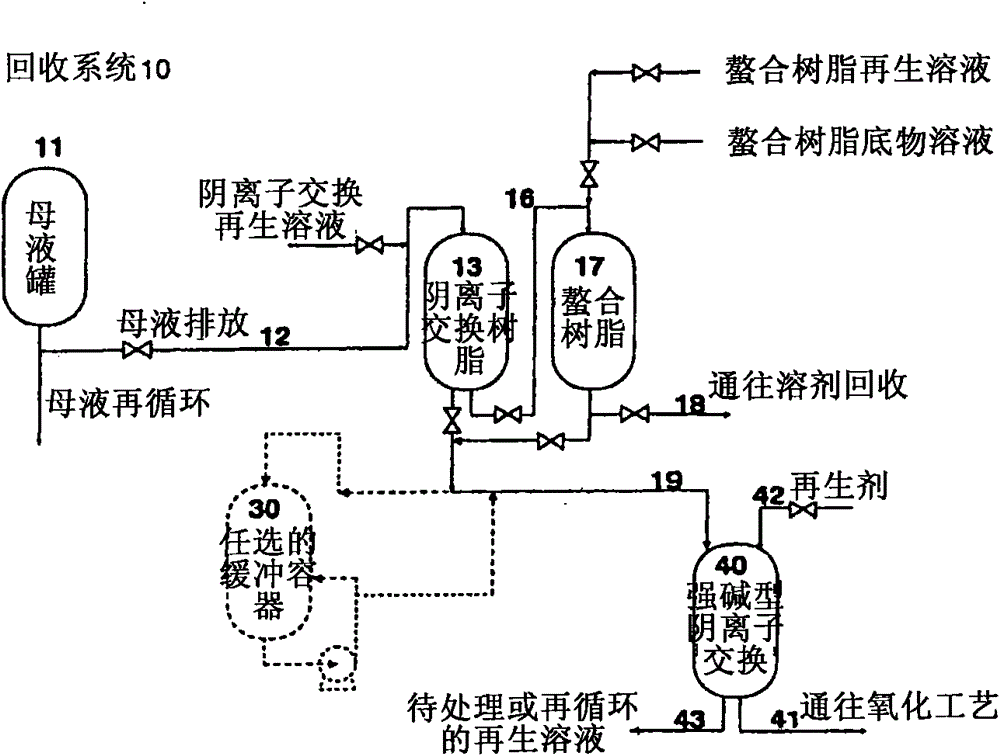

[0066] Connect columns A and C in series, something like figure 1 The structure shown in , where resin bed 13 is column A and resin bed 17 is column C. The feed stream to column A contained heavy metals and halogens, reaction solvents, oxidation reaction by-products and oxidation reaction intermediates, and corrosion products in the concentrations reported in Table 1. The feed stream was heated to 7OC. 500ml of glacial acetic acid was pumped through the two resin beds, then the stream to be tested was fed into the resin beds and recovered on the discharge side of the last bed. Keep the column jacket temperature constant during the test. After adsorption, the test stream was removed from the column by pumping glacial acetic acid through both beds. By using 100% water as the regenerant for column A, a solution consisting of acetic acid / HBr / water=90 / 4 / 6% by weight as the substrate for column C, and 100% aqueous solution as the The regeneration solution performs regeneration. ...

Embodiment 2

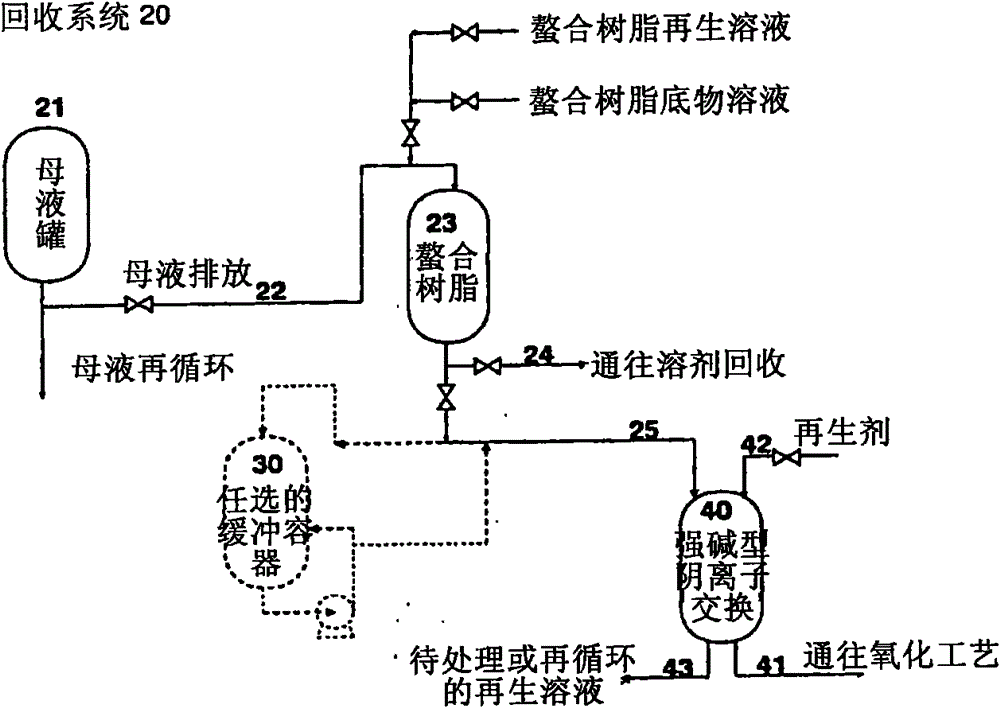

[0071] Except only testing column C, making the structure similar to figure 2 The procedure used in Example 1 was repeated except that column C was resin bed 23, as shown in . Regeneration was performed by using a solution consisting of acetic acid / HBr / water=90 / 4 / 6% by weight as a substrate for column C and 100% aqueous solution as a regeneration solution for column C. The relevant data are reported in Table 1.

Embodiment 3

[0073] Test column B such that the structure resembles figure 1 and figure 2 As shown in , where column B is the resin bed 40. Representing figure 1 and 2 The feed stream compositions for the compositions of streams 19 and 25 are reported in Table 1. 500ml of glacial acetic acid was pumped through the resin bed, then the stream to be tested was fed into the resin bed and recovered on the discharge side of the bed itself. The column jacket temperature was kept constant during the test. After adsorption, the test stream was removed from the column by pumping water through the bed. The relevant data are reported in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com