Method for the production of permanent magnets and a permanent magnet

A manufacturing method and technology of permanent magnets, which are applied in the manufacture of permanent magnets, inductors/transformers/magnets, magnetic objects, etc., can solve the problems of poor magnetic properties, low production efficiency, and troublesome disposal, and achieve strong corrosion resistance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

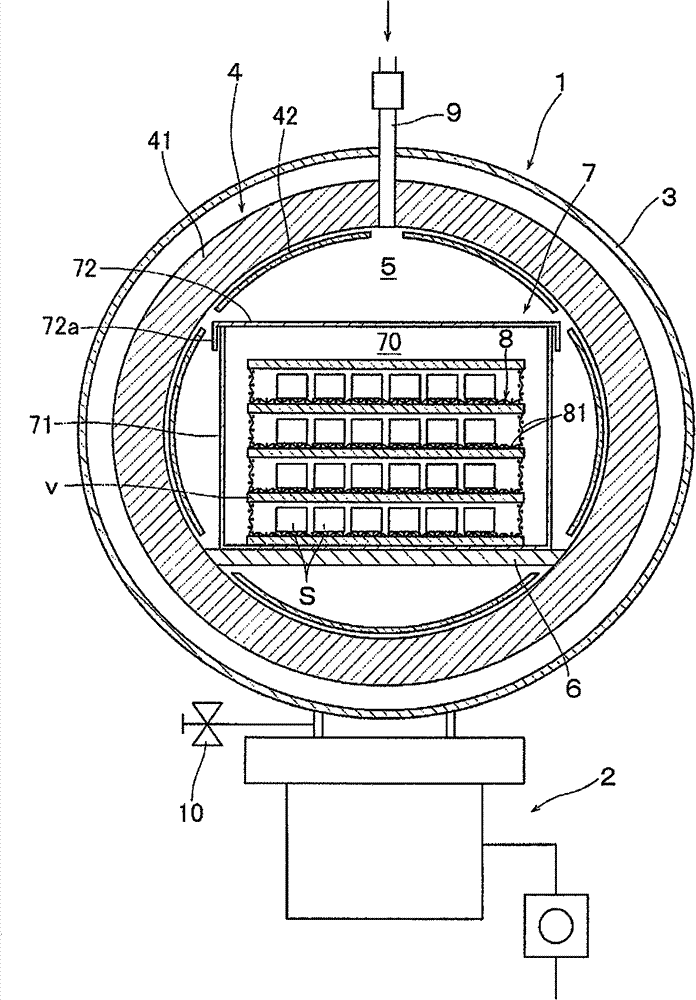

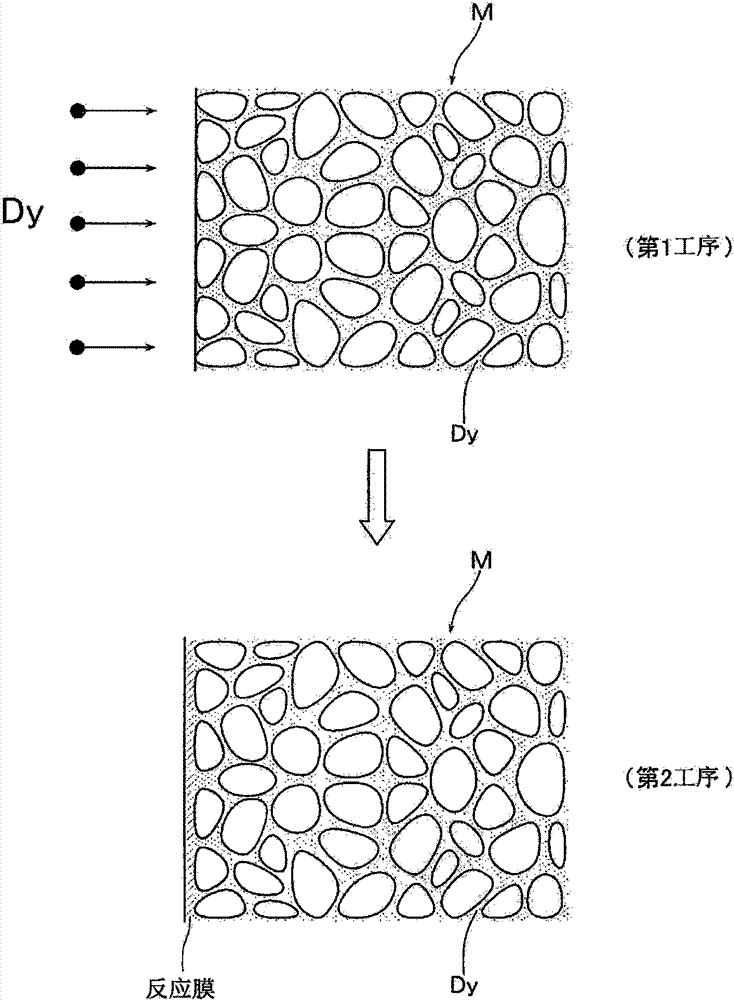

[0065] In Example 1, with figure 1 In the vacuum vapor treatment apparatus 1 shown in , the permanent magnet M is obtained by performing the first step and the second step on the sintered magnet S below. For the sintered magnet S, a commercially available 40H sintered magnet was purchased (composition ratio:

[0066] 28.5(Nd+Pr)-3Dy-0.05Co-0.05Cu-0.01Zr-0.05Ga-1.1B-Bal.Fe), processed into a cube of 10×10×10mm, and cleaned the surface.

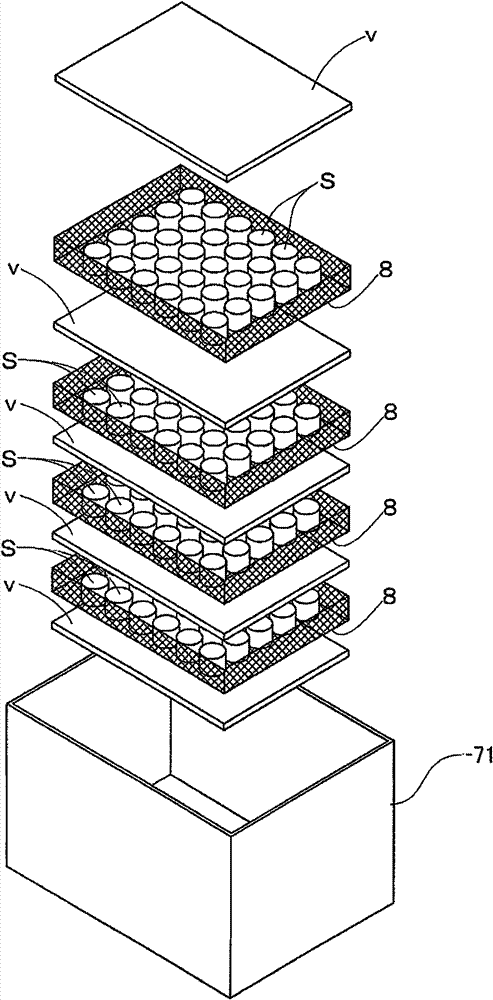

[0067] Next, use figure 1 The shown vacuum steam treatment apparatus 1 applies vacuum steam treatment to the sintered magnets S (five at a time) produced separately as described above. In this case, using 5 mm thick Dy (purity 99.5%) as the metal evaporation material v, a total of 5 g of Dy was placed on the bottom surface of a treatment box made of Ta, and a sintered magnet S was placed on the upper side of Dy. Gaskets made of it. Then the pressure in the vacuum chamber 3 reaches 10 -5 After Pa, the heating device 4 was operated, the temp...

Embodiment 2

[0072] In Example 2, with figure 1 In the vacuum vapor treatment apparatus 1 shown in , the permanent magnet M is obtained by performing the first step and the second step on the following sintered magnet S. As the sintered magnet S, a commercially available 45H sintered magnet was purchased (composition ratio:

[0073] 25.5(Nd+Pr+Ho)-3.5Dy-1Co-0.15Cu-0.15Ti-0.05Sn-0.95B-Bal.Fe), processed into a cube of 7×7×7mm, and cleaned the surface.

[0074] Next, use figure 1 The vacuum vapor treatment apparatus 1 shown in , applies vacuum vapor treatment to the sintered magnets S (10 pieces at a time) prepared separately as described above. In this case, using 0.5 mm thick Dy (purity 99.5%) as the metal evaporation material v, a total of 5 g of Dy was placed on the bottom surface of a treatment box made of Ta, and a sintered magnet S was placed on the upper side of Dy. Gaskets made of Ta. Then the pressure in the vacuum chamber 3 reaches 10 -4 After Pa, the heating device 4 was ope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com