Edible pig blood and industrial production method thereof

A production method and technology of pig blood, applied in application, food preparation, food science and other directions, can solve the problems of inferior products and unstable agglutination methods, and achieve the effect of prolonging the shelf life and improving the taste and flavor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

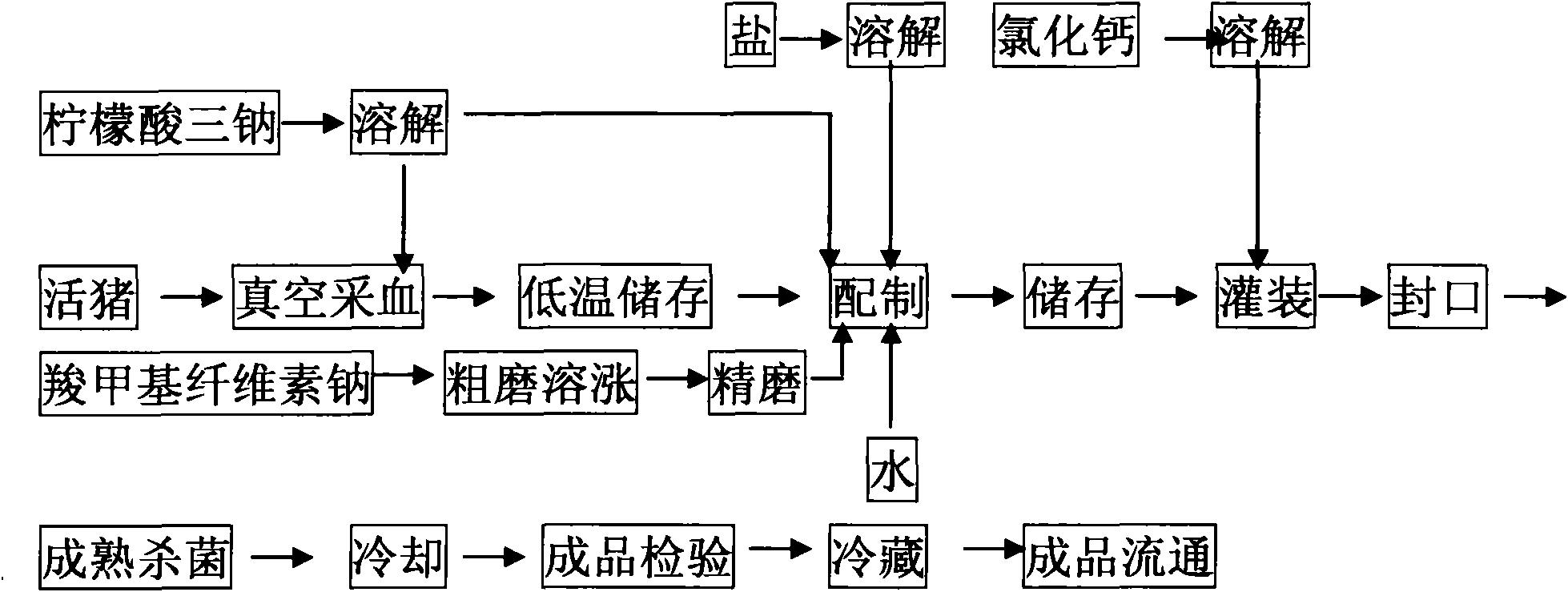

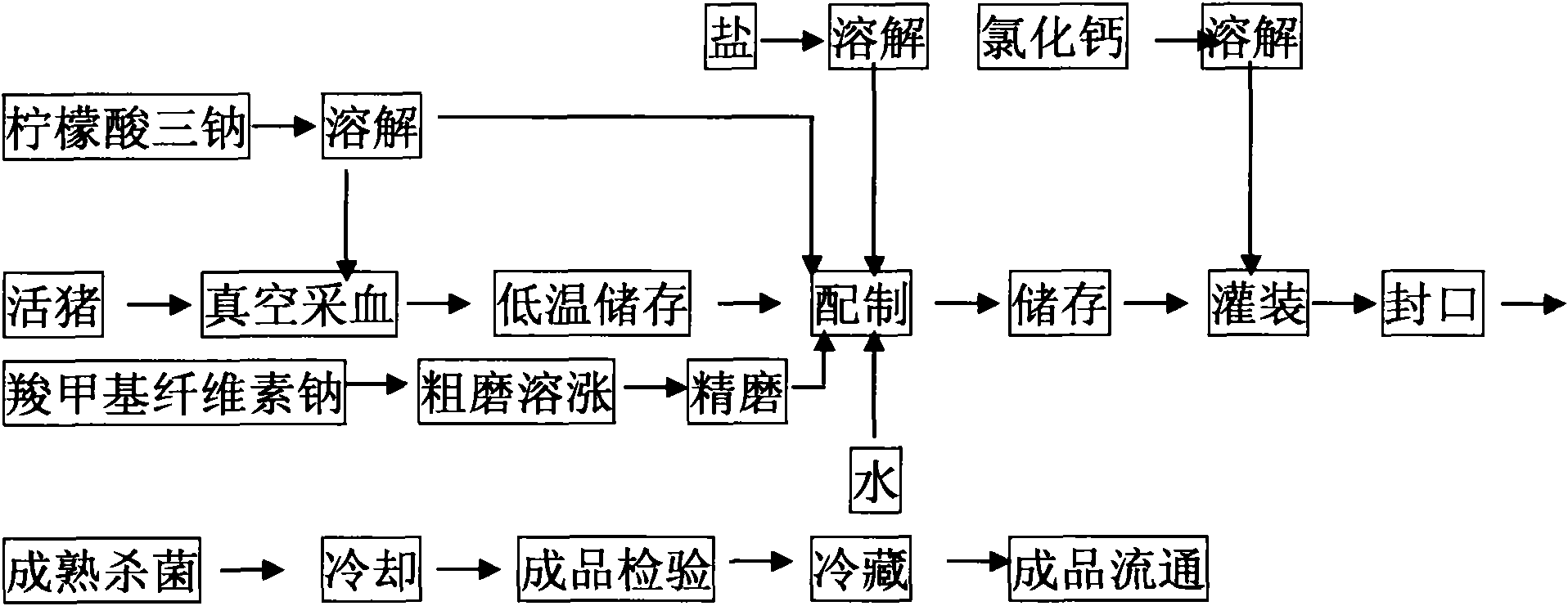

Method used

Image

Examples

Embodiment 1

[0049] 1) Pig blood, salt, trisodium citrate, sodium carboxymethylcellulose, calcium chloride and water are prepared in a weight ratio of 33:1:0.2:0.2:0.6:65.

[0050] 2) Preparation of 5% trisodium citrate: add trisodium citrate into water, stir well to dissolve, remove impurities with an 80-mesh sieve, and set aside.

[0051] 3) Vacuum collection of pig blood: when blood collection (blood collection speed 200mL / min), add trisodium citrate with a concentration of 5% to prevent coagulation of pig blood in the blood collection tube; immediately transport the collected pig blood to 0-4°C Cool in the warehouse, cool to below 15°C, and set aside.

[0052] 4) Preparation of sodium carboxymethyl cellulose: Add sodium carboxymethyl cellulose to water, use a colloidal film to coarsely grind it with a fineness of 20 grids to obtain a coarsely ground sol; swell the coarsely ground sol for 8 hours, and then use a colloidal film Grinding with a fineness of 10 grids to obtain a finely gro...

Embodiment 2

[0069] The difference between Example 2 and Example 1 is that in step 1), pig blood, salt, trisodium citrate, sodium carboxymethylcellulose, calcium chloride and water are mixed in a ratio of 50:0.5:0.1:0.1:0.3: 49 weight ratio stock.

[0070] All the other steps are the same as in Example 1.

[0071] The parameters of the detected boxed pig blood products are as follows:

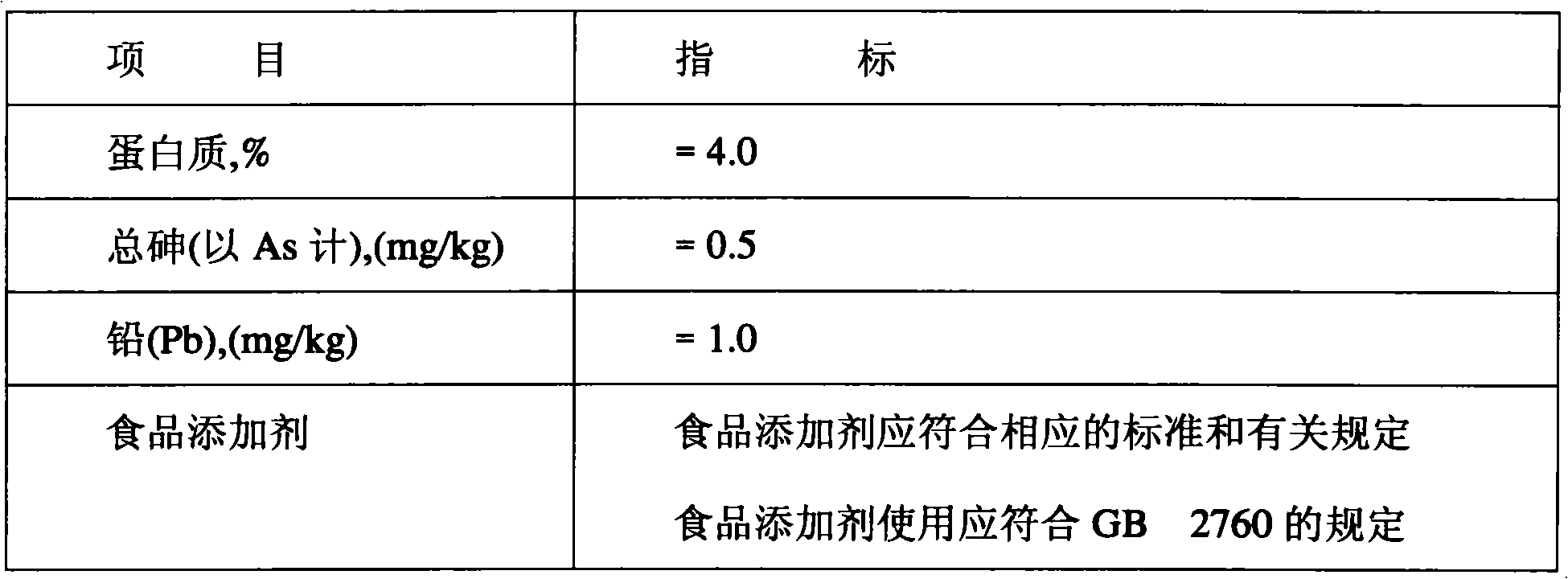

[0072] 1) Sensory indicators meet the requirements of Table 1;

[0073] 2) The physical and chemical hygiene indicators meet the requirements in Table 2;

[0074] 3) The microbial indicators meet the requirements in Table 3;

[0075] 4) Pig blood has a high water content and a fresh taste;

[0076] 5) After 15 days of storage at 0-4°C, only 3mL of water precipitates out, and the product quality is stable.

Embodiment 3

[0078] The difference between Example 3 and Example 1 is that in step 1), pig blood, salt, trisodium citrate, sodium carboxymethylcellulose, calcium chloride and water are mixed in a ratio of 40:0.8:0.15:0.15:0.5: 58.4 weight ratio to stock.

[0079] All the other steps are the same as in Example 1.

[0080] The parameters of the detected boxed pig blood products are as follows:

[0081] 1) Sensory indicators meet the requirements of Table 1;

[0082] 2) The physical and chemical hygiene indicators meet the requirements in Table 2;

[0083] 3) The microbial indicators meet the requirements in Table 3;

[0084] 4) Pig blood has a high water content and a fresh taste;

[0085] 5) After 15 days of storage at 0-4°C, only 4mL of water precipitated out, and the product quality was stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com