Device and method for processing counterbore of circuit board

A processing device and circuit board technology, applied in metal processing equipment, printed circuits, manufacturing tools, etc., can solve problems such as low processing efficiency, broken tool handle, reduced tool life, etc., and achieve convenient use and adjustment, increase stability, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

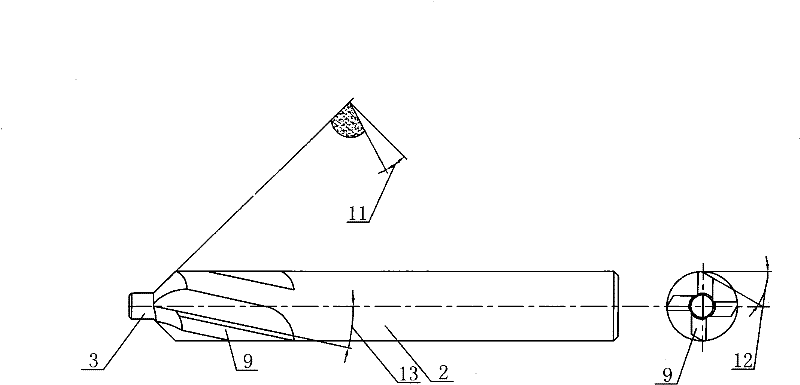

[0052] Embodiment 1: as figure 1 , image 3 and Figure 5 as shown, figure 1 Shown is a schematic diagram of the structure of the tapered countersink with an angle of 90°, and as Figure 5 Shown is a schematic diagram of the structure of the countersinking tool combined with the depth control device, in which the diameter of the tool holder 2 at the clamping end is changed from φ3.175mm to the same diameter as the drilling part, that is, the diameter of the drilling part is 8mm, and the tool holder The diameter is also 8mm; the diameter of the positioning guide post 3 is designed according to the customer's requirements, and the diameter of the counterbore hole 7 of the circuit board is the same, but the tolerance requirement is φd -0.05 -0.1 , the surface roughness reaches Guarantee better cooperation with the bottom hole 7 of the counterbore hole of the circuit board; the number of main / minor cutting edges 9 is increased from the normal 2 to 4, and at the same time, ...

Embodiment 2

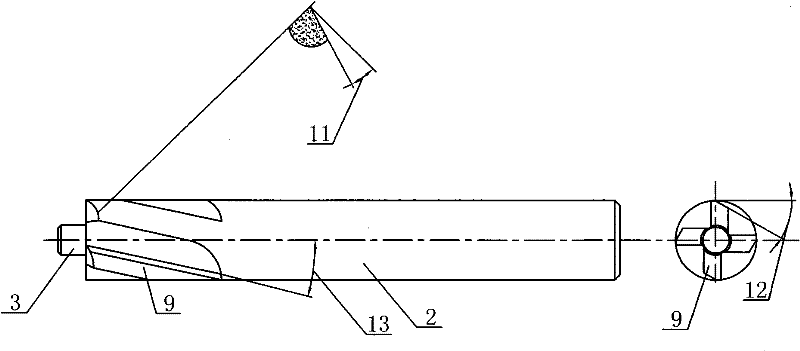

[0055] Embodiment 2: as figure 2 , Figure 4 and Figure 5 shown. figure 2 Shown is a schematic diagram of the structure of a flat countersink, that is, the cone angle changes from 90° to 180° (flat head). Figure 5 The schematic diagram of the structure of the countersink drilling and countersinking combined with the depth control device is shown. Since the structure of the clamping end shank 2 at the rear end of the countersink with different shapes is the same, the installation structure diagram of the flat countersink will not be drawn here ( Figure 5 The countersinking tool in the center has changed from a countersinking tool with a cone angle of 90° to a flat countersinking tool), the diameter of the cutting part and the diameter of the handle 2 at the clamping end are changed to the same as the customer’s final hole diameter, and the diameter of the positioning guide post 3 is based on customer requirements. Others The parameters such as the number of major and mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com